Section 22: HEATING AND AIR CONDITIONING

PA1553

29

safe. A color indication of light blue to light violet

indicates the caution range of moisture level.

For positive protection, the drying of the system

should be continued until the color of the

element turns to deep blue.

The liquid refrigerant is readily visible through

the center opening of the moisture element

where the presence of bubbles indicates a

shortage of refrigerant or restriction in line.

Moisture is one of the main causes of chemical

instability or contamination in air conditioning

systems. If moisture is present, it can corrode

the valves, condenser and evaporator coils,

compressor and other components causing a

malfunction and eventual failure of the system.

Uncontrolled moisture in the system can result

in very expensive multiple component replace-

ments if not corrected at an early stage. The

moisture indicator permits an early detection of

moisture in the system and when corrected by a

desiccant charge, system contamination is

greatly minimized.

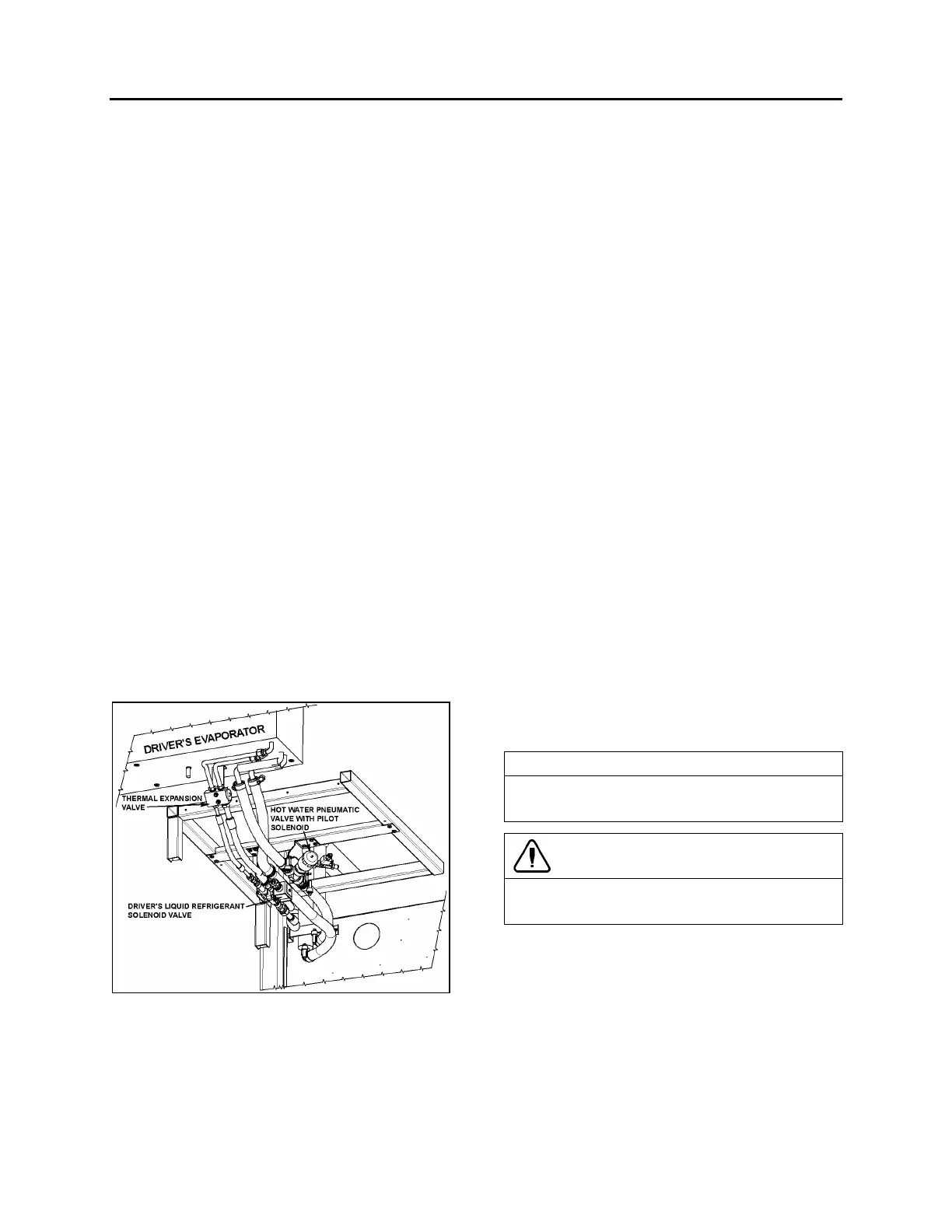

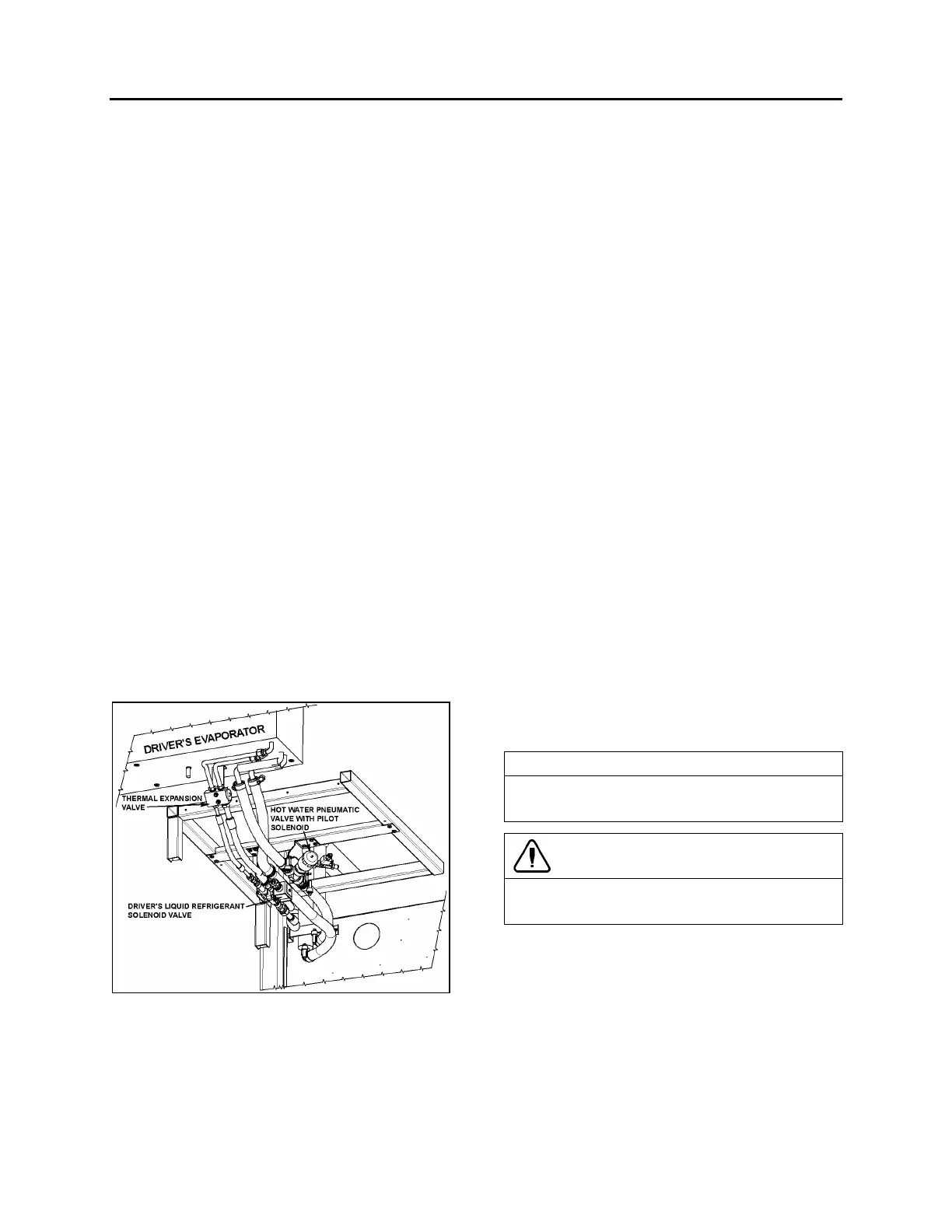

9.7 LIQUID REFRIGERANT SOLENOID

VALVE

The flow of liquid refrigerant to the driver’s and

main evaporators is controlled by a normally-

closed solenoid valve (Refer to fig. 31 & 32).

The driver’s liquid refrigerant solenoid valve is

located on the ceiling of the spare wheel and tire

compartment and is accessible through the

reclining bumper.

FIGURE 32: DRIVER'S LIQUID REFRIGERANT

SOLENOID VALVE

22181

9.7.1 Manual Bypass

This type of solenoid valve is equipped with a

manual operating stem. The 3/16" square stem

located on the bonnet is exposed when the seal

cap is removed. To manually open valve, turn

stem ½ turn counterclockwise. To manually

close valve, turn stem clockwise until tight

against seat. Manual stem must be in closed

position for automatic electric operation.

9.7.2 Coil Replacement

1. Disconnect connector from the coil

connector.

2. Take out the retaining screw at the top of

the coil housing. The entire coil assembly

can then be lifted off the enclosing tube.

3. Place the new coil and yoke assembly on

the enclosing tube. Lay data identification

plate in place.

4. Insert the coil retaining screw, rotate

housing to proper position and tighten screw

securely.

5. Connect connector from coil connector.

9.7.3 Valve Disassembly

1. Remove the coil as stated previously.

2. Pump down the system as stated earlier in

this section.

3. Remove the four socket head screws which

hold the body and bonnet together (Fig. 33).

4. Carefully lift the bonnet assembly off (upper

part of the valve) so that plunger will not fall

out. The diaphragm can now be lifted out.

NOTE

The above procedure must be followed before

brazing solder-type bodies into the line.

CAUTION

Be careful not to damage the machined faces

while the valve is apart.

9.7.4 Valve Reassembly

1. Place the diaphragm in the body with the

pilot port extension up.

2. Hold the plunger with the synthetic seat

against the pilot port.

3. Make sure the bonnet O-rings are in place.

Lower the bonnet assembly over the

plunger, making sure that the locating

Loading...

Loading...