Section 12: BRAKE AND AIR SYSTEM

PA1553

7

Change cartridge every 100,000 miles (160 000

km) or once every two years, whichever comes

first. The air dryer may be purged for mainte-

nance purposes using the remote drain valve

located in the engine compartment and

accessible through the engine compartment

R.H. side door. The valve is positioned over the

battery assembly, close to the door hinge or

close to the L.H. side of door opening depending

on type of vehicle (Fig. 2). The air filter/dryer has

a built-in governor to maintain the system

between 108 psig and 123 psig.

Maintenance and repair information is supplied

in the maintenance information annexed to this

section.

7.1 AIR FILTER/DRYER PURGE TANK

A tank is supplied to purge the air filter/dryer to

remove moisture and contaminants.

8. AIR LINES

Copper piping, nylon-reinforced tubing, and

flexible hoses are used to connect the units in

the pneumatic system, including air brake

system, suspension system and accessory

systems such as the entrance door, fresh air

damper cylinder, air horns, etc. Furthermore, the

nylon tubing is color coded to ease identification.

Refer to the following table for the complete

color identification code. Service instructions for

each type of air line are also provided under the

applicable headings.

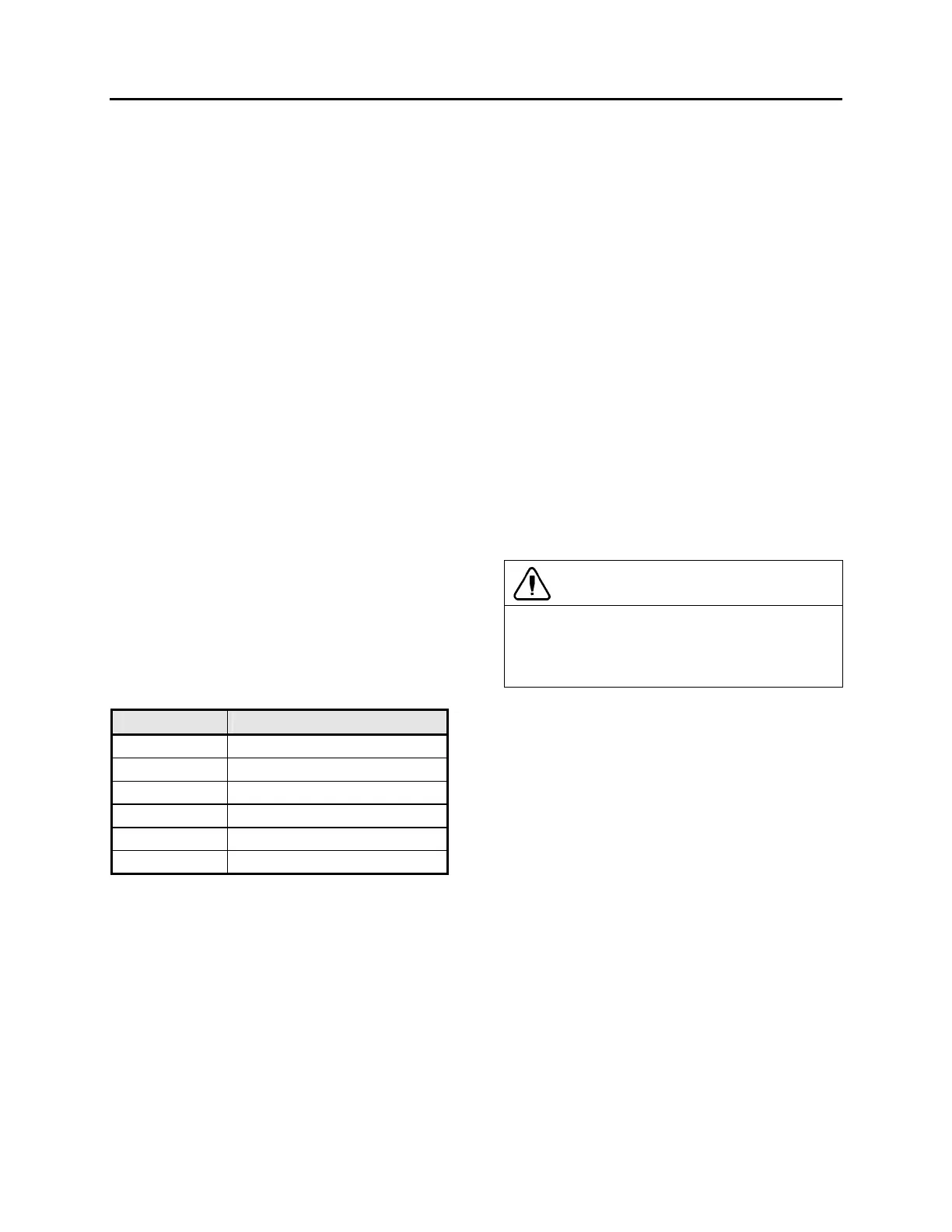

Color Circuit

Red Secondary

Green Primary and Delivery

Yellow Parking Brake

Blue Suspension

Black Accessory

Brown Trailer Brake

8.1 COPPER PIPING

A heat dissipation copper piping assembly is

used to dissipate the heat coming from the

compressor before it enters the air filter/dryer.

Connections should be checked for leakage at

least every 6,250 miles (10 000 km) or twice a

year, whichever comes first. Tighten or replace

when necessary. When replacing copper piping,

the parts must be free of burrs, copper cuttings,

and dirt. Blow out piping with compressed air.

Any such particles will destroy sealing seats in

air control units. Also, new piping must be the

same size as the old one.

8.2 FLEXIBLE HOSES

A flexible hose is used normally where it is

impractical to use copper or nylon tubing due to

constant flexing during operation, such as brake

chamber hoses. Hose connections should be

tested for leakage at least every 6,250 miles

(10 000 km) or twice a year, whichever comes

first and tightened or replaced if necessary. Any

hose which is chafed, worn or kinked should be

replaced.

Teflon-braided stainless steel hoses used in the

engine compartment must be replaced only with

similar hoses.

8.3 NYLON TUBING

Nylon tubing is used for air lines in areas where

usage of this material is suitable. Nylon tubing is

flexible, durable, and weather resistant. When

replacing an air line, use nylon tubing only

where it has been used previously.

Nylon air lines must never be routed in areas

where temperature could exceed 200

o

F (93

o

C).

CAUTION

Nylon air lines should be used to replace

existing nylon lines only, and must comply

with the color identification code to ease

pneumatic system troubleshooting.

8.4 AIR LINE OPERATING TEST

If any trouble symptom such as slow brake

application or slow brake release indicates a

restricted or clogged air line, disconnect the

suspected tube or hose at both ends and blow

through it to clear the passage.

Inspect tubing and hose for partial restriction

that may be caused by dents or kinks. If such a

condition is found, the tubing or hose should be

replaced.

8.5 AIR LINE LEAKAGE TEST

With air system fully charged and the brakes

applied, coat all tubing and hose connections

with a soapy solution to check for air leakage.

No leakage is permitted. Leakage can

sometimes be corrected by tightening the

connection. If this fails to correct the leakage,

new fittings, nylon tubing, copper tubing,

teflon-braided stainless steel and flexible hoses

must be installed as applicable.

Loading...

Loading...