Section 26: XLII SLIDE-OUT

PA1553

14

8 JAW COUPLING

8.1 MAINTENANCE

Inspect the jaw couplings to check if there is

backlash between the key and the keyway. Also,

check the spider condition. Check that the

clamping screws are tight.

8.2 REPLACEMENT &

ADJUSTMENT

1. The slide-out must be retracted.

2. Disengage the jaw coupling: loosen the

clamping screw on each clamping hub. If

required, rotate the motor shaft extension as

described in the manual override procedure

(section 18) to get to the clamping screws.

3. Separate both clamping hubs.

NOTE

It may be necessary to loosen the blue flange

bearings to move the shaft out of the way.

4. Clean and degrease the hub bore and the

shaft.

5. Push the new clamping hubs onto the shaft

(pinion side).

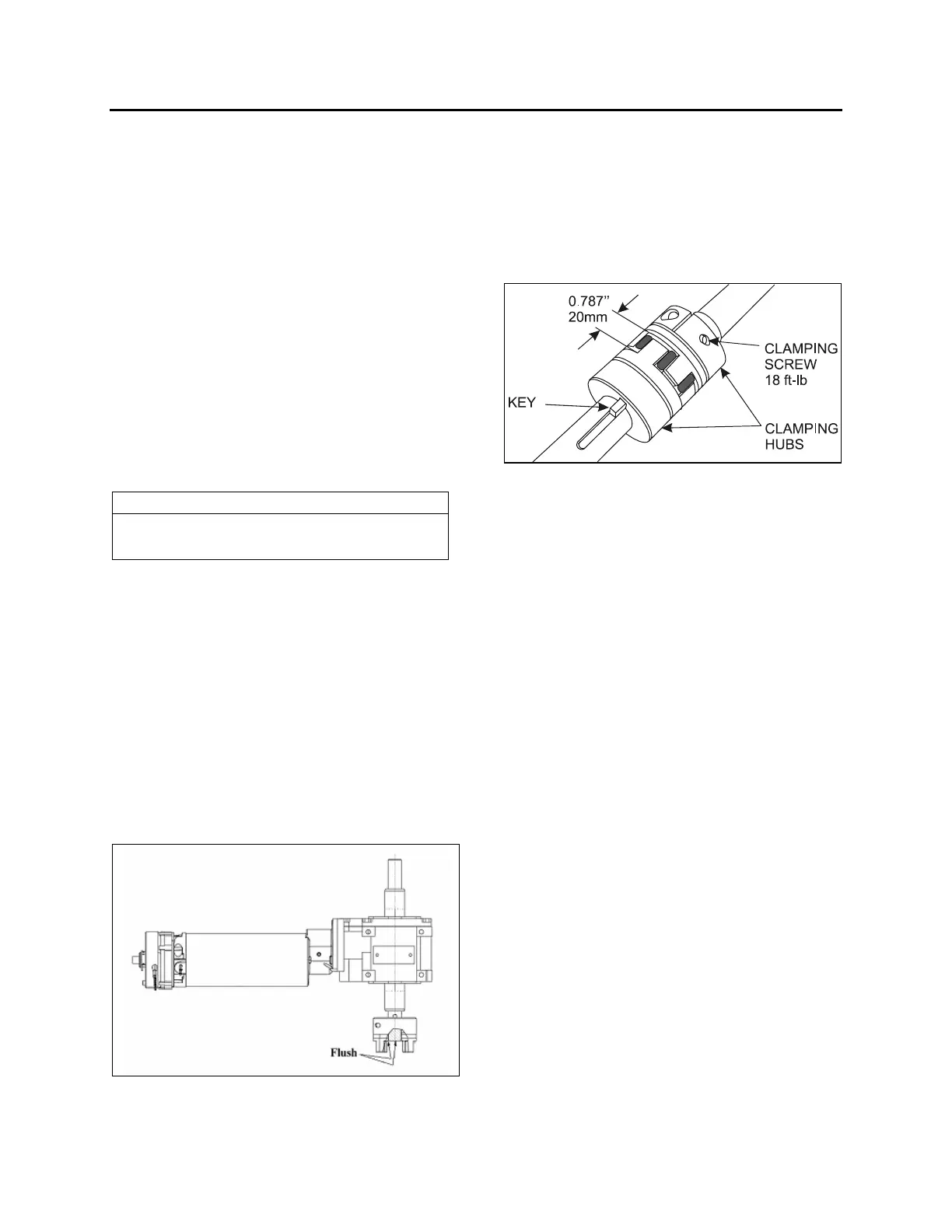

6. Install a clamping hub on one of the gearbox

shaft (opposite side of gearbox mounting

bolts) flush with the shaft extremity (FIGURE

19). Tighten the clamping screw to a torque

of 18 lbf-ft.

7. Install the second clamping hub on the

gearbox shaft. Position the clamping hubs

so that they are flush with the shafts

extremity (see FIGURE 19).

FIGURE 19: CLAMPING HUB POSITION ON GEARBOX

SHAFT

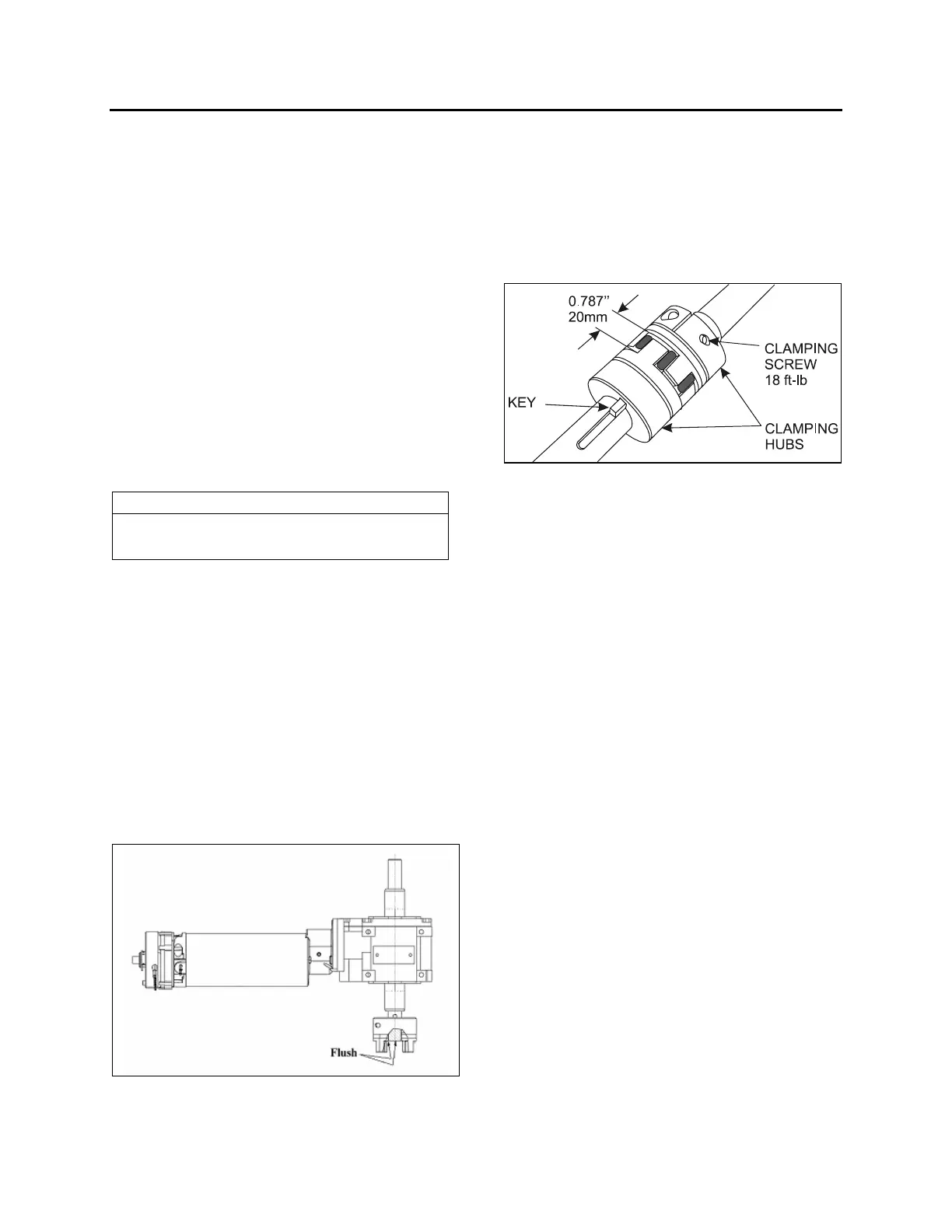

8. Reconnect the clamping hubs with the

spider. Leave a gap of 20mm (0.787inch)

between each clamping hubs as shown on

FIGURE 20. Use the motor hexagonal

socket output shaft to align the keyways.

9. Tighten clamping screws to a torque of 18

lbf-ft.

FIGURE 20: JAW COUPLING

9 FLANGE BEARING

There are two different types of flange bearing

on the slide-out mechanism (FIGURE 13). Their

purpose is to maintain the shaft in position while

permitting rotation. The gray flange bearings are

fixed to the linear bearing support plate and are

not adjustable. The blue flange bearings are

fixed to a support with oblong holes permitting to

raise or lower the flange bearing as the linear

bearing support plate level is being adjusted.

The flange bearings are pre-lubricated and no

subsequent lubrication is required due to the

very low extending and retracting speed of the

slide-out system.

10 LOCKING COLLAR

The locking collar locks the shaft and the flange

bearing together using friction. Once locked, it

permits no axial translation of the shaft and

prevents rotation of the shaft into the flange

bearing bore.

10.1 INSTALLATION

Slide the locking collar along the shaft up to the

flange bearing (FIGURE 13). Turn the locking

collar clockwise while maintaining it pressed

against the flange bearing. Knock the collar with

a punch to lock it in place, there is a cavity on

the collar made for that purpose. Tighten the set

screw.

Loading...

Loading...