Section 05: COOLING SYSTEM

PA1553

6

4. COOLANT

4.1 COOLANT LEVEL VERIFICATION

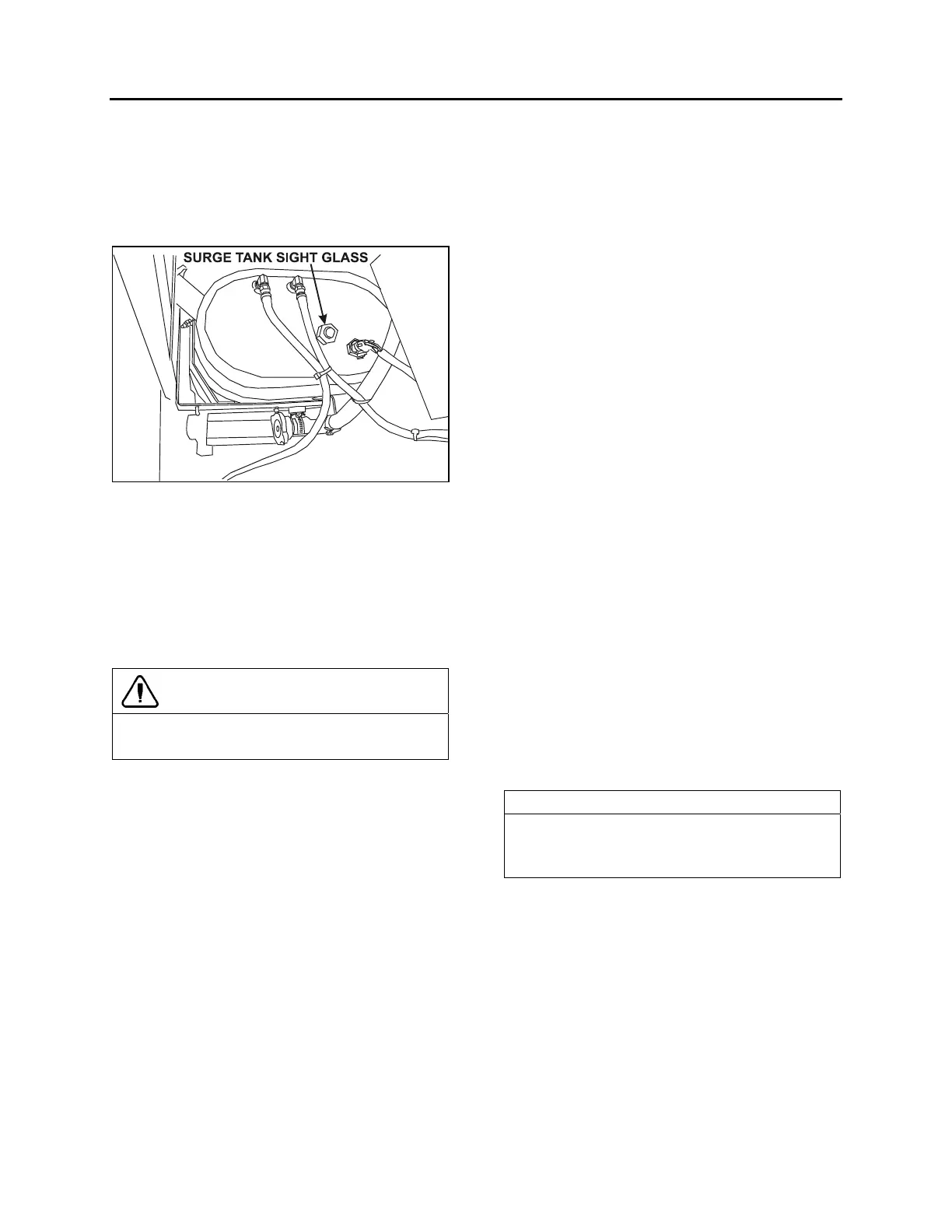

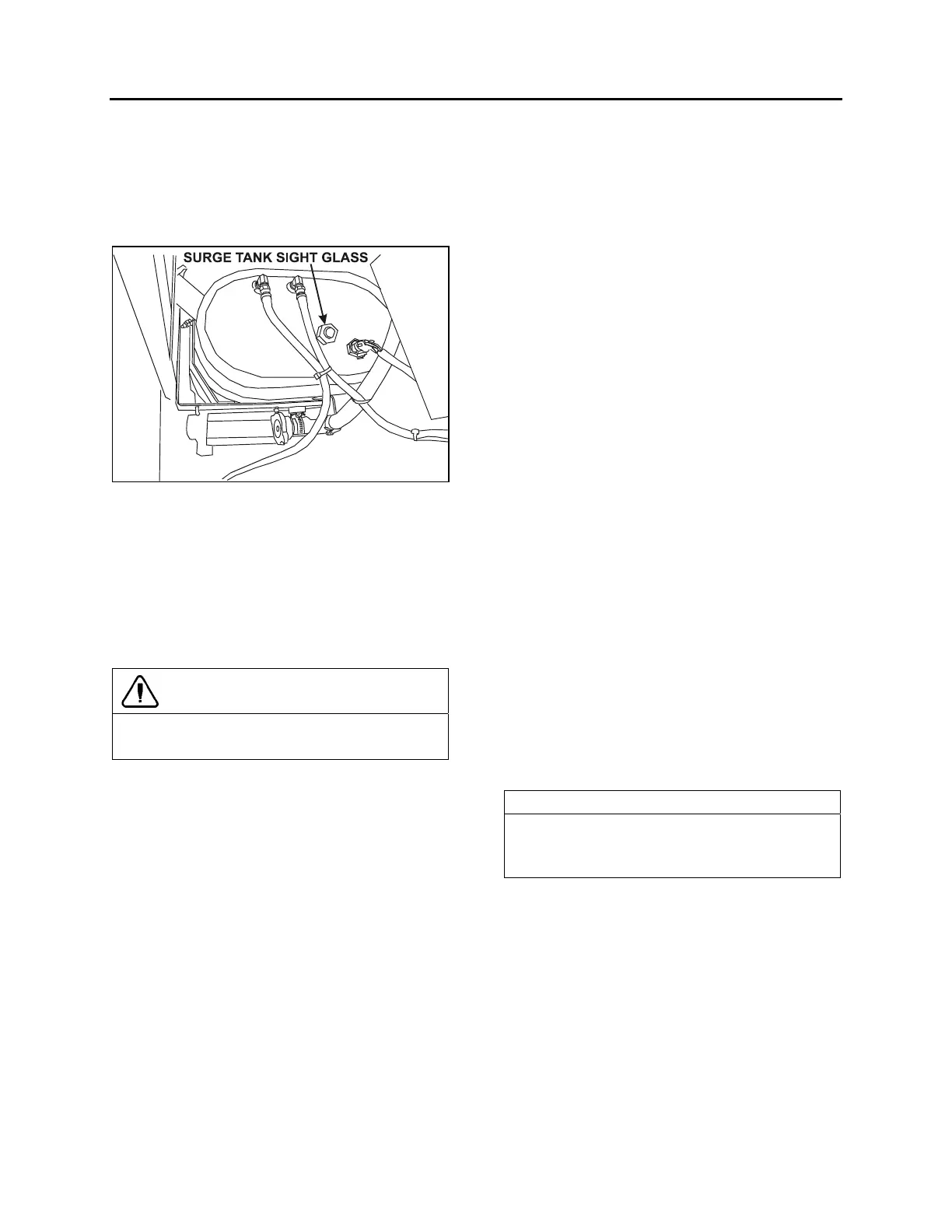

Coolant level is correct when cold coolant is

visible through the surge tank sight glass

(Fig. 4). If coolant level is low, fill cooling system.

FIGURE 4: SURGE TANK SIGHT GLASS 05094

4.2 COOLANT LEVEL SENSOR

This warning device consists of a fluid level

probe mounted on the surge tank. The probe

sends a signal to the ECM to indicate coolant

level. If the coolant level drops below the probe,

the "Check Engine" light flashes and a

diagnostic code is registered (see section 01"

ENGINE").

CAUTION

Do not run engine with the “Check Engine”

light flashing.

The level probe is mounted on the R.H. side of

the surge tank while the electronic module is

mounted inside the rear electric junction box.

4.3 THAWING COOLING SYSTEM

If the cooling system becomes frozen solid,

place the coach in a warm area until the ice is

completely thawed. Under no circumstances

should the engine be operated when the cooling

system is frozen, as it will result in engine

overheating due to insufficient coolant.

Once thawed, check engine, radiator and

related components for damage caused by

expansion of frozen coolant fluid.

4.4 COOLANT REQUIREMENTS

The coolant provides a medium for heat transfer

and controls the internal temperature of the

engine during operation. In an engine having

proper coolant flow, some of the combustion

heat is conveyed through the cylinder walls and

the cylinder head into the coolant. Without

adequate coolant, normal heat transfer cannot

take place within the engine, and engine

temperature rapidly rises. Coolant must

therefore be carefully selected and properly

maintained.

Select and maintain coolant in order to meet the

following basic requirements:

o Provide for adequate heat transfer.

o Provide protection from cavitation damage.

o Provide a corrosion and erosion resistant

environment within the cooling system.

o Prevent formation of scale or sludge

deposits in the cooling system.

o Be compatible with the cooling system hose

and seal materials.

o Provide adequate freeze protection during

cold weather operation.

Combining suitable water with reliable inhibitors

satisfies the first five requirements. When freeze

protection is required, a solution of suitable

water and antifreeze containing adequate

inhibitors will provide a satisfactory coolant fluid.

Ethylene glycol-based antifreeze is

recommended for use in Series 60 engines. The

cooling system capacity is 24 US gal (91 liters).

NOTE

In general, antifreeze does not contain

adequate inhibitors. For this reason,

supplemental coolant additives are required.

For a complete overview of engine coolants

used with Detroit Diesel Engines, refer to

"Coolant Selections" For Engine Cooling

Systems Guide at the end of this section

(#7se298).

4.5 COOLING SYSTEM RECOMMENDATIONS

Always maintain cooling system at the proper

coolant level. Check daily.

The cooling system must be pressurized to

prevent localized boiling of coolant. The system

must be kept clean and leak-free. The filler and

Loading...

Loading...