Section 05: COOLING SYSTEM

PA1553

14

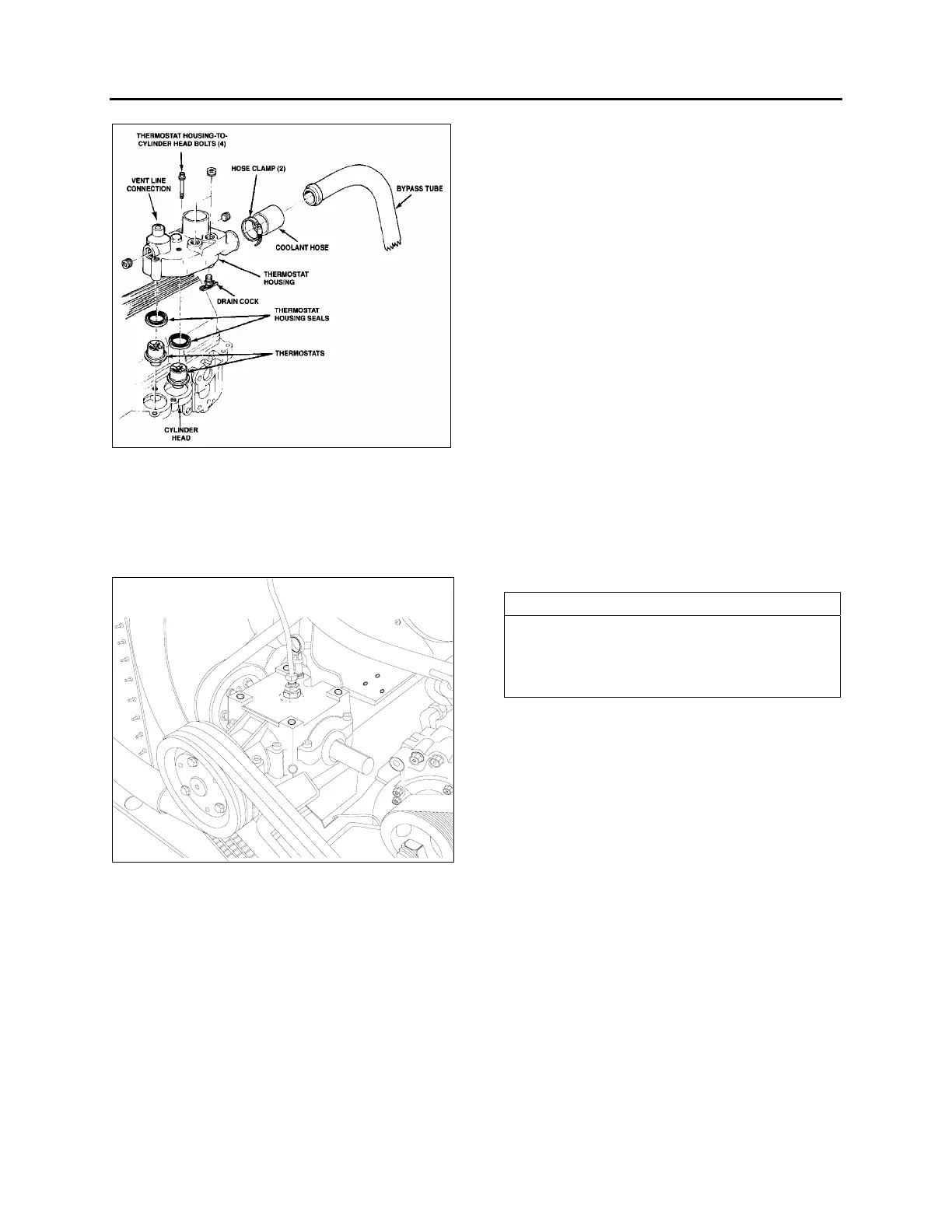

FIGURE 14: THERMOSTAT AND RELATED PARTS 05034

11. FAN GEARBOX

The radiator fan is belt driven from the engine

crankshaft pulley through a standard gearbox,

which is designed with two output shafts.

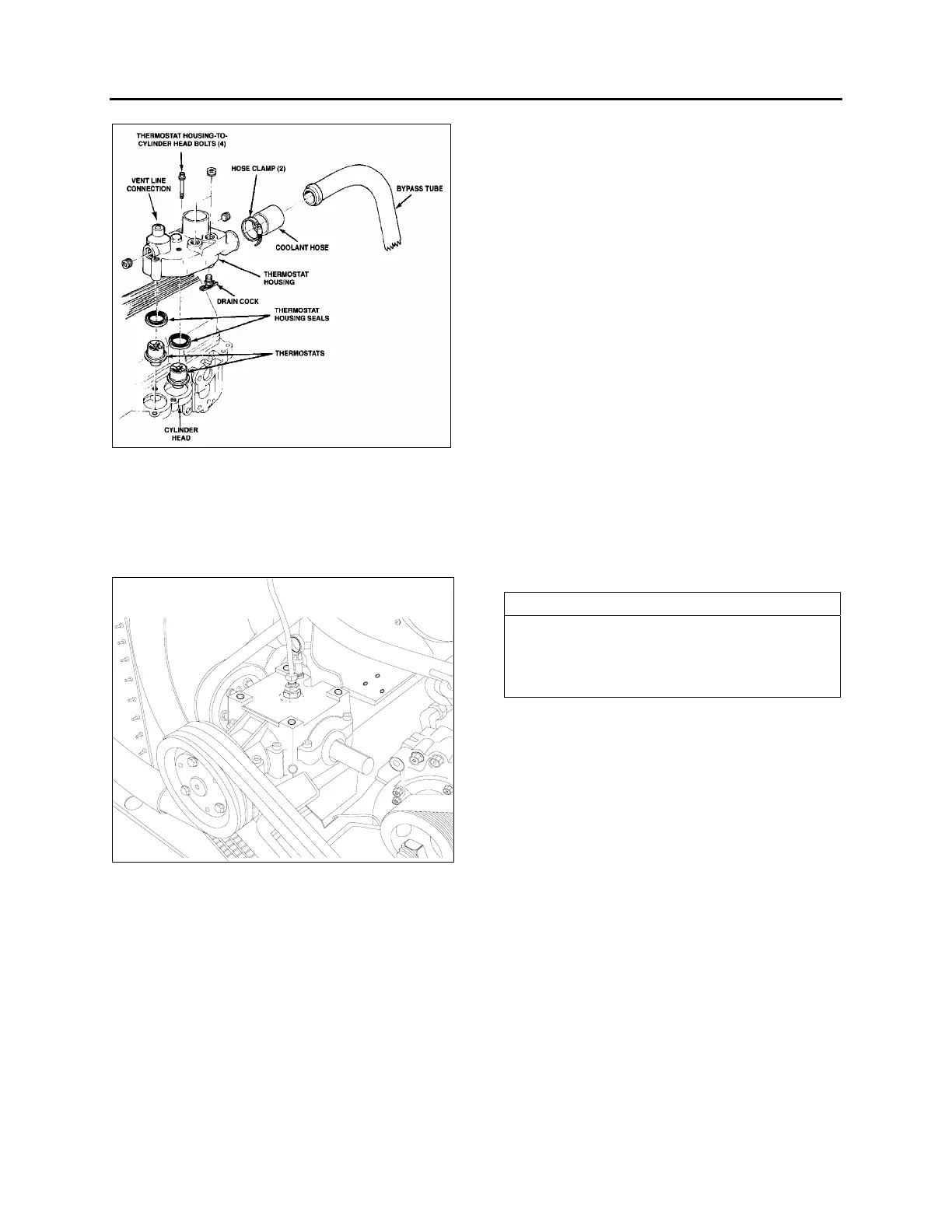

FIGURE 15: FAN GEARBOX 05062

11.1 MAINTENANCE

Change the gearbox oil at 3,000 miles (4,800

km) and subsequently every 50,000 miles

(80,000-km) or once a year, whichever comes

first.

11.2 OIL CHANGE

1. Stop engine and make sure that all engine

safety precautions have been observed.

2. Remove the drain plug located underneath

the gearbox case.

3. Drain gearbox.

4. Replace drain plug.

5. Remove the dipstick located on top of

gearbox and wipe with a clean rag (Fig. 15).

6. Adjust level to ″Full″ mark using Mobil SHC

630 (Prévost #180217) synthetic oil.

7. Insert dipstick in gearbox case, then remove

again to check mark.

8. Reinsert the dipstick.

12. RADIATOR FAN BELT REPLACEMENT

Locate the belt tensioner pressure-releasing

valve (Fig. 16), then turn handle counter-

clockwise in order to release pressure in belt

tensioner air bellows, thus releasing tension on

belts.

Remove existing belts (3″V″belts & 1 Poly) from

fan assembly and replace with new ones.

Turn the pressure-releasing valve clockwise to

its initial position to apply tension on the new

belts.

NOTE

For proper operation of the belts, adjust the

air bellows tensioner pressure regulating

valve (located next to control valve) to 45 psi

(310 kPa).

12.1 BELT TENSION ADJUSTMENT

The regulator is located in the engine

compartment behind the belt tension pressure

releasing valve panel. Turn the screw located

under the regulator assembly to change the

tension pressure. Check proper pressure using

the pressure check valve (Fig. 16).

Use Belt Tension Gauge #68-2404 to measure

tension of engine belts. For proper operation of

air tensioners, adjust upper tensioning bracket

to provide a ¼" (7 mm) gap between stopper

and bracket under normal pressure of 45 psi -

310 kPa. Refer to figure 16 for more information.

Loading...

Loading...