Section 22: HEATING AND AIR CONDITIONING

PA1553

21

4. Check compressor oil level to ensure

compressor is not overcharged with oil.

Sometimes a significant amount of oil is

pumped out of the compressor to other

parts of the system when a compressor

fails. This oil will return to the replacement

compressor when it is started, causing an

overcharge of oil in the sump of the

replacement compressor. In this case, it is

important that the oil level be adjusted to

the proper level.

5. Withdraw a sample of the compressor oil and

check its color, odor, and acidity, using

instructions supplied above. If the oil is

contaminated, change the oil and filter dryer,

and repeat the procedure until the system is

clean.

8.7.3 Clean-out After Major Compressor

Failure

1. Reclaim the refrigerant into a refrigerant

bottle through a filter dryer to filter out

contaminants.

2. Remove the failed compressor and repair it if

possible.

3. Install new or repaired compressor.

4. Change the filter dryer.

5. Circulate clean R-134a or nitrogen with the

reclaimer to clean out many of the

contaminants collected in the coil valves,

TXV (Thermal Expansion Valve), solenoid

valves, check valves, and any other

mechanical component that may have

collected contaminants.

6. Evacuate and charge the system normally.

7. Run the unit for 8 hours and monitor the

pressure drop across the filter dryer. Also

check the liquid line dryer for signs of

restriction. If the pressure drop across the

filter dryer exceeds 12 to 14 psig (82,75 to

96,5 kPa) with a 40°F (5°C) evaporator coil

temperature, stop the unit and change the

liquid line and suction line filter dryer. After 4

or 5 hours of operation, stop the unit and

replace the filter dryer.

8. After 8 hours of operation, stop the unit and

remove a sample of the compressor oil and

check its color, odor, and acidity, using

instructions supplied above. If the oil is

contaminated, replace the oil and repeat step

7. If the oil is not contaminated, change the

filter dryer again and replace the moisture-

liquid indicator.

9. After approximately 7 days of operation,

recheck the compressor oil for cleanliness

and acidity.

9. CENTRAL HVAC SYSTEM – AIR

CONDITIONING COMPONENTS

9.1 COMPRESSOR (CENTRAL SYSTEM)

9.1.1 Belt Replacement

DANGER

Turn the ignition key switch to the “Off”

position. For greater safety, trip circuit

breakers CB1 & CB2 and set the engine

starter selector switch in engine compartment

to the “Off” position.

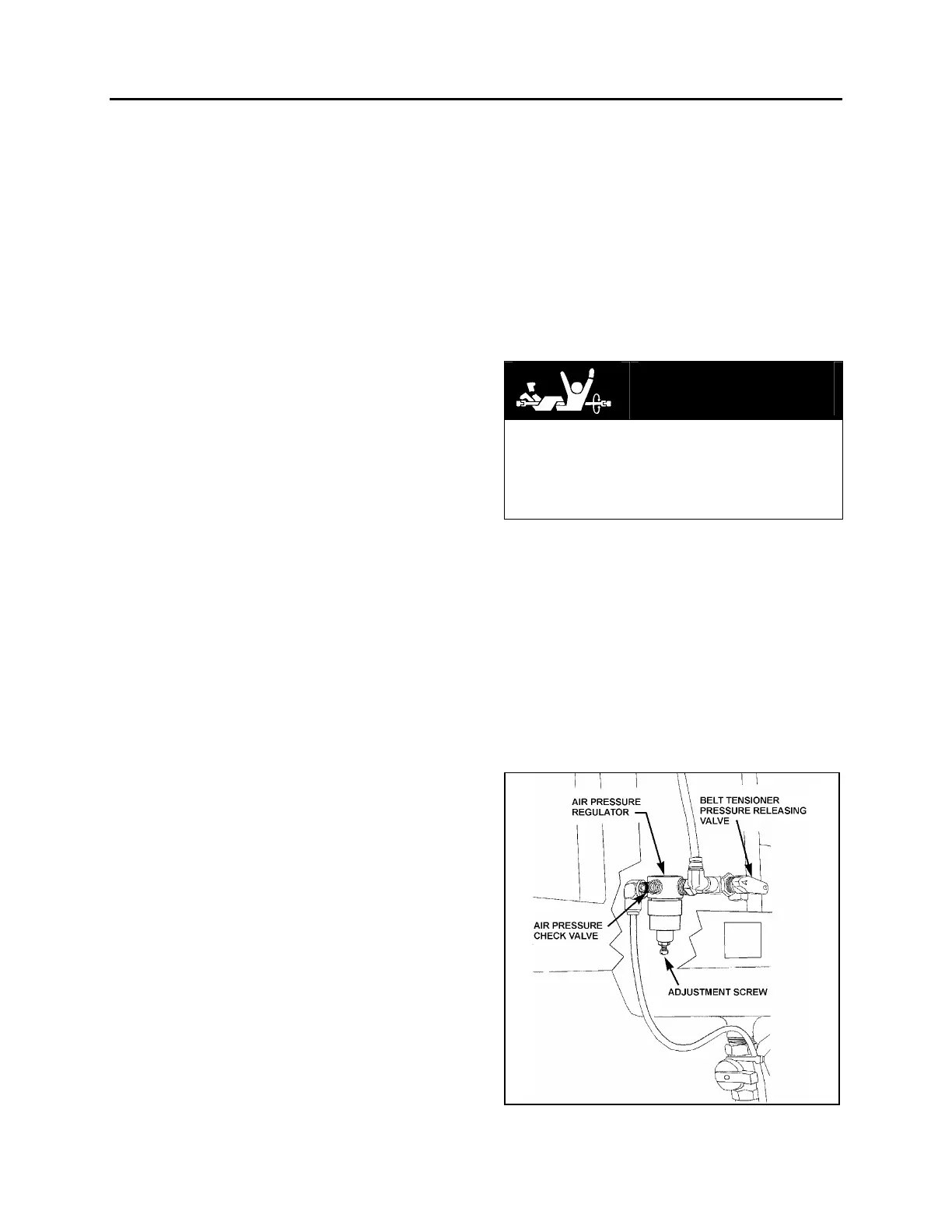

1. Open engine compartment rear doors and

locate the belt tensioner pressure releasing

valve (Fig. 18), mounted above the engine

R.H. side door next to the air pressure

regulator, then turn handle clockwise in

order to release pressure and tension on

belts.

2. Slip the old belts off and the new ones on.

3. Reset belt tensioner pressure releasing

valve (Fig. 18) to 45 psi (310 kPa) to apply

tension on the new belts as explained in

Section 12.

FIGURE 18: AIR PRESSURE REGULATOR 12200

Loading...

Loading...