Section 22: HEATING AND AIR CONDITIONING

PA1553

42

6. Charge the system with the proper amount

of refrigerant through the service port near

the check valve using recommended

charging procedures.

7. Remove the hoses.

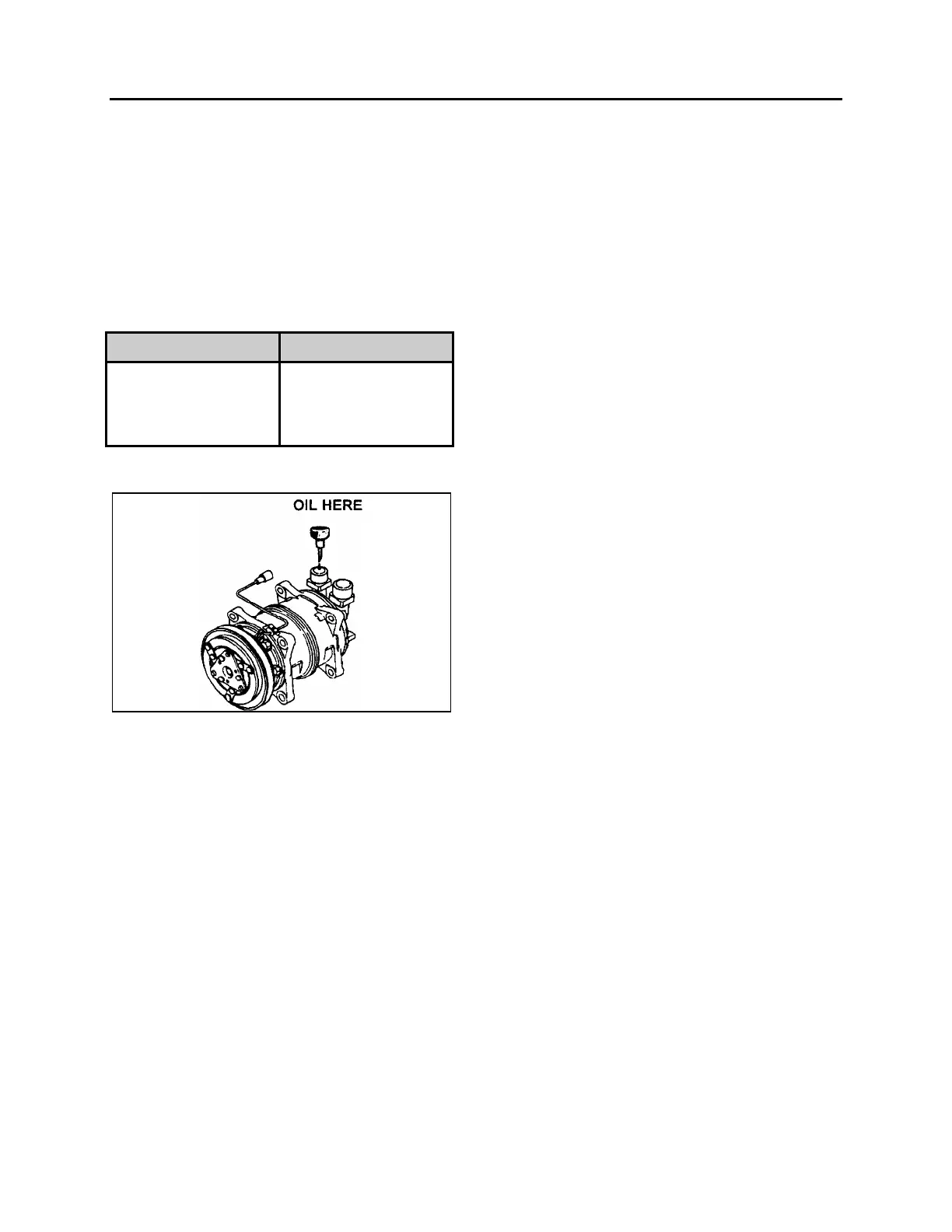

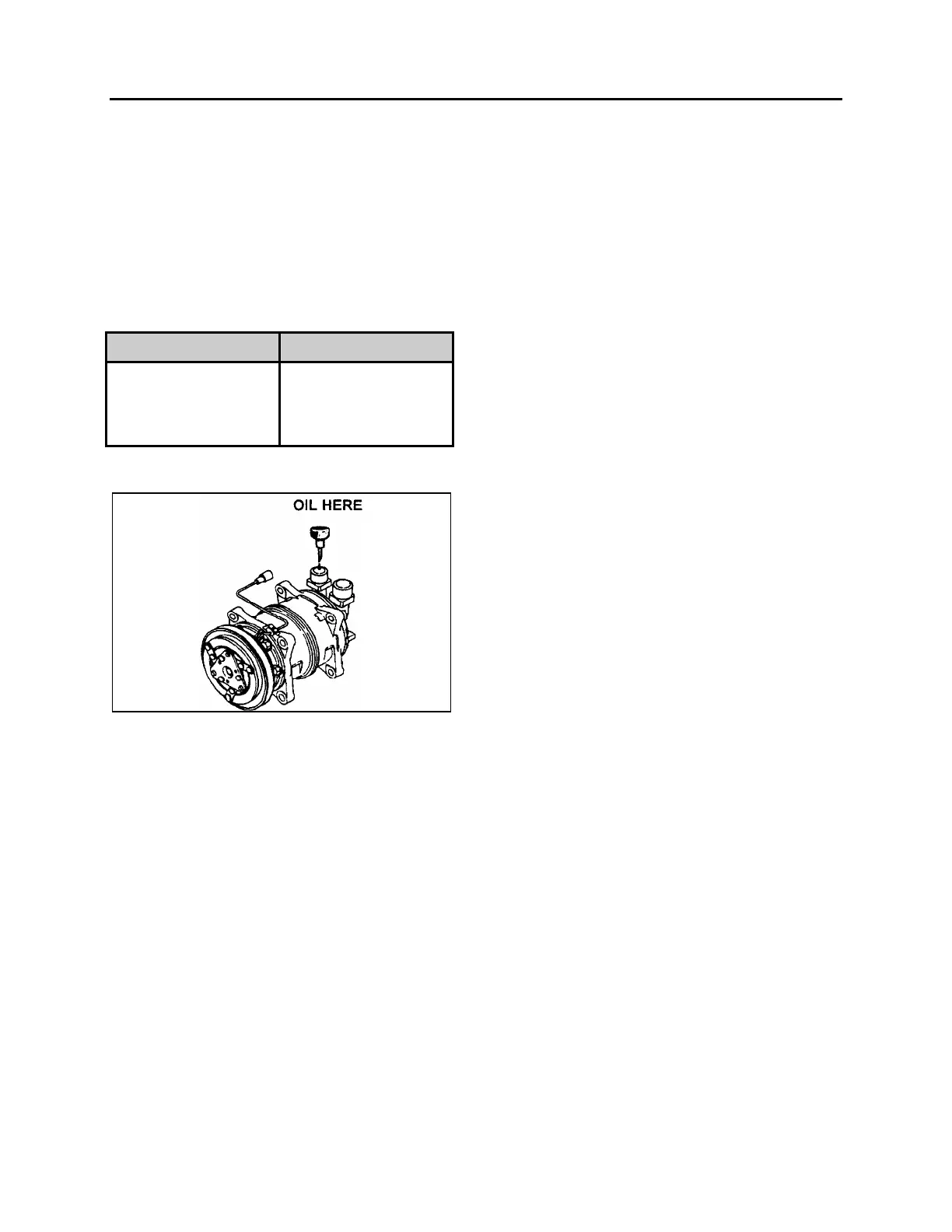

10.7 OIL ADDITION

The chart below shows the approximate amount

of oil to be added to the system when replacing

a component.

Component replaced Typical amount of oil

Evaporator

Condenser

Filter-Dryer

50 cm³ (1.7 ozs)

30 cm³ (1.0 ozs)

10 cm³ (0.3 ozs)

The amount of oil recovered with the refrigerant

recovery should be added at the same time.

FIGURE 47: ADDING OIL AFTER REPLACING A

COMPONENT

10.8 COMPRESSOR OIL CONTAMINATION

Unlike engine oil, no cleaning agent is added to

the compressor oil. Even if the compressor is

run for a long time, the oil never becomes turbid

as long as there is nothing wrong with the

compressor or its method of use. Inspect the

extracted oil for any of the following conditions:

* Dirt in the oil.

* Change to a varnish color.

* Presence of foreign substance, metal

shavings, etc. in the oil. When the oil

extracted from the compressor is as

described above, replace the oil as follows:

1. Clean the interior of the system with

approved method.

2. Replace the filter-dryer.

3. Supply with new oil as specified in

paragraph 10.6: “COMPRESSOR OIL

CHANGE”.

10.9 OIL RETURN OPERATION

There is a close affinity between oil and

refrigerant. During normal operation, part of the

oil recirculates with the refrigerant in the system.

Therefore, when checking the amount of oil in

the system or replacing any system component,

the compressor must be run in advance to

ensure return. This procedure is as follows:

* If the amount of refrigerant in the system has

decreased, charge to the proper amount.

* Start the engine and select fast idle.

* Set the fan speed to full air/full A/C and let

run for 20 minutes.

10.10 OIL CHECK INTERVAL

Unlike engine oil, it is not necessary to

frequently check or change the compressor oil.

However, it is necessary to check and replenish

or replace the compressor oil in the following

cases:

* Whenever the compressor, evaporator,

condenser or filter-dryer is replaced.

* Whenever refrigerant has leaked from the

system, evaluate the amount of oily spot.

* Whenever refrigerant is suddenly released

from the cooling cycle, replenish the

compressor (180 ml) plus 150 ml.

* Whenever any oil-related problems occur in

the cooling cycle.

10.11 LEAK TEST PROCEDURE WITH

COMPRESSOR REMOVED

When a compressor is repaired, it must be

checked prior to installation.

* Install the discharge and suction caps to the

connector.

Loading...

Loading...