Section 22: HEATING AND AIR CONDITIONING

PA1553

43

FIGURE 48: DISCHARGE AND SUCTION CAPS

* Fill the compressor with refrigerant through

connector’s suction port raising the pressure

to at least 0.5 Mpa (70 psi).

* Check the compressor for leaks using a leak

detector.

NOTE

Never leave the compressor upside down for

longer than 30 seconds. This is because the

oil inside the compressor will enter the

cylinders, causing liquid compression which

will damage the compressor’s suction and

delivery valves.

10.12 TIGHTENING TORQUES

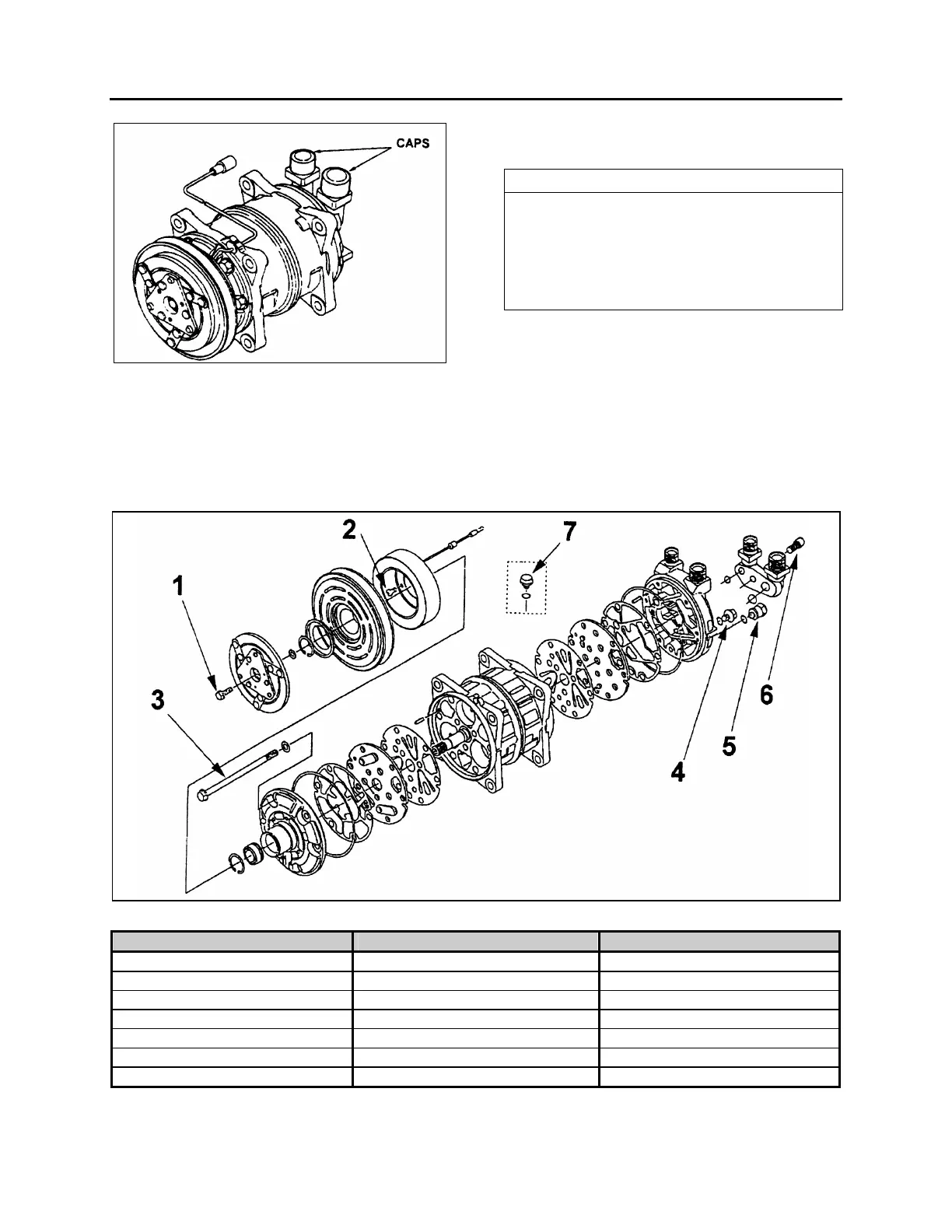

FIGURE 49: TIGHTENING TORQUES

PART THREAD SIZE TIGHTENING TORQUE

1. Bolt Armature M6 x 1.0 12 - 14 Nm (8.7 - 10.1 Lbf-Ft)

2. Field Coil Screw M5 x 0.8 4 - 6 Nm (2.9 - 4.3 Lbf-Ft)

3. Body Bolt M8 x 1.25 20 – 24 Nm (14.5 – 17.3 Lbf-Ft)

4. Oil Drain Plug M8 x 1.25 13 – 15 Nm (9.4 – 10.8 Lbf-Ft)

5. Pressure Relief Valve 3/8 – 24UNF 13 – 15 Nm (9.4 – 10.8 Lbf-Ft)

6. Connector Bolt M8 x 1.25 20 – 24 Nm (14.5 – 17.3 Lbf-Ft)

7. Oil Filler Plug M8 x 1.25 13 – 15 Nm (9.4 – 10.8 Lbf-Ft)

Loading...

Loading...