Section 13: WHEELS, HUBS & TIRES

PA1553

2

1. WHEELS

When the vehicle is provided with stud-mounted

wheels, wheel studs and nuts on the left side of

the vehicle have left-hand threads whereas

those on the right side have right-hand threads.

If equipped with hub-mounted wheels, all studs

and nuts have right-hand threads. Aluminum-

polished wheels are installed on the vehicle and

are mounted with radial tubeless tires.

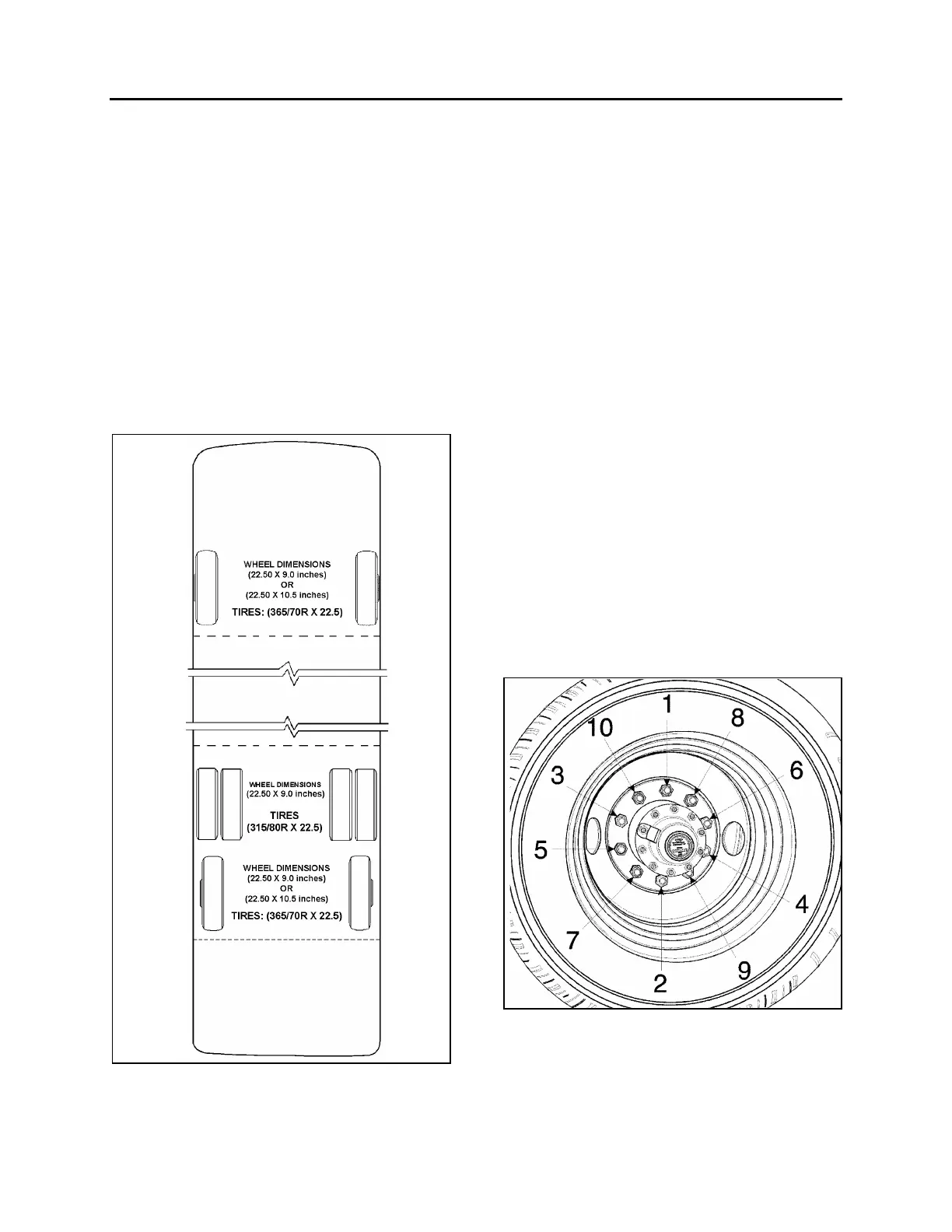

Drive axle wheel dimensions are 22.50 X 9.0

inches (571.5 X 228.6 mm) for 315/80 R 22.5

tires while front and tag axle wheels may either

be 22.50 X 9.0 inches (571.5 X 228.6 mm) or

22.50 X 10.5 inches (571.5 X 266.7 mm) for

365/70 R 22.5 tires. Dura-Bright coating on

aluminum wheels is optional.

FIGURE 1: WHEEL ARRANGEMENT 13037

2. WHEEL MAINTENANCE

Wheel maintenance consists of periodic

inspections. Check all parts for damage and

make sure that wheel nuts are tightened to the

proper torque. In the case of a new vehicle, or

after a wheel installation, stud nuts should be

tightened every 100 miles (160-km) for the first

500 miles (800-km) to allow setting in of

clamping surfaces.

Wheel studs and nuts must be kept free from

grease and oil. No lubricant whatsoever should

be used. Cleanliness of the wheel and its rotor

mating surfaces is important for proper wheel

mounting.

However, for hub mounted wheels, it is

recommended to add some rust protection

lubricant on the pilot diameter of the hub (to

facilitate future removal).

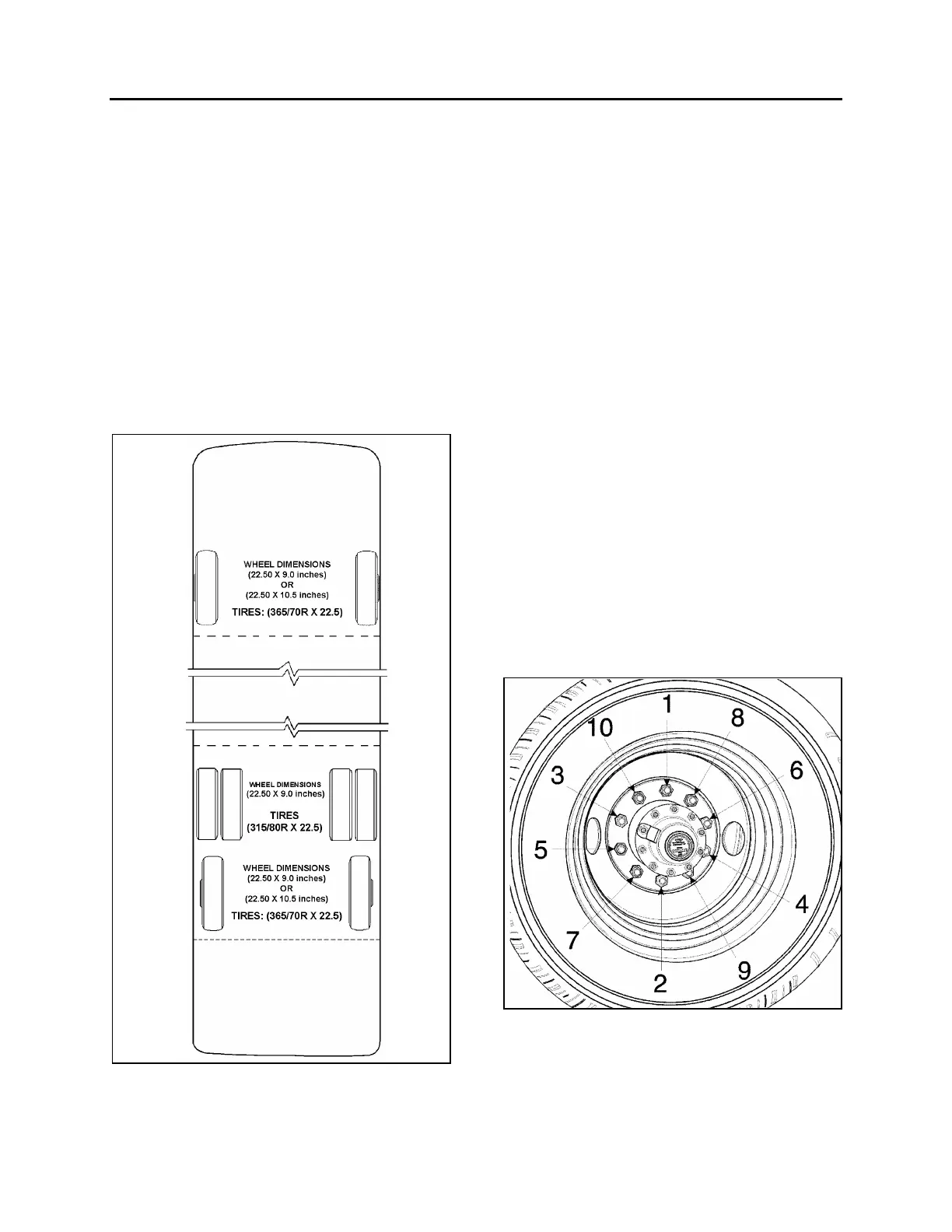

It is also important that wheel stud nuts be

tightened alternately on opposite sides of the

wheel. Refer to Figure 2 for the suggested

tightening sequence.

2.1 INSPECTION

Tighten stud nuts progressively as shown in

Figure 2. The final tightening should be done

with a torque wrench. Tighten stud nuts to 450 -

500 lbf-ft (610 - 680 Nm) for aluminum wheels.

FIGURE 2: TIGHTENING SEQUENCE 13018

Loading...

Loading...