Section 26: XLII SLIDE-OUT

PA1553

10

CAUTION

Make sure the keyless bushing is tightened to

125 lb-ft before moving the slide-out. Refer to

section 5.4.1 for torque wrench settings.

5.3 REAR SLIDE-OUT SHAFT

PINION REPLACEMENT

The procedure is similar to the front slide-out

shaft pinion replacement. Gain access to the

mechanism from under the bed structure. Refer

to section 5.2.

5.4 KEYLESS BUSHING

The keyless bushings need a specific tightening

torque value to ensure proper pinion transmitting

torque. They also need specific tools to be

tightened.

To tighten or loosen the keyless bushing, use

those specific tools:

- crowfoot wrench 1 ½";

- torque wrench;

- combination wrench 1 ¾";

- pipe wrench;

- drive extension 5";

- socket 1 ½".

5.4.1 Installation

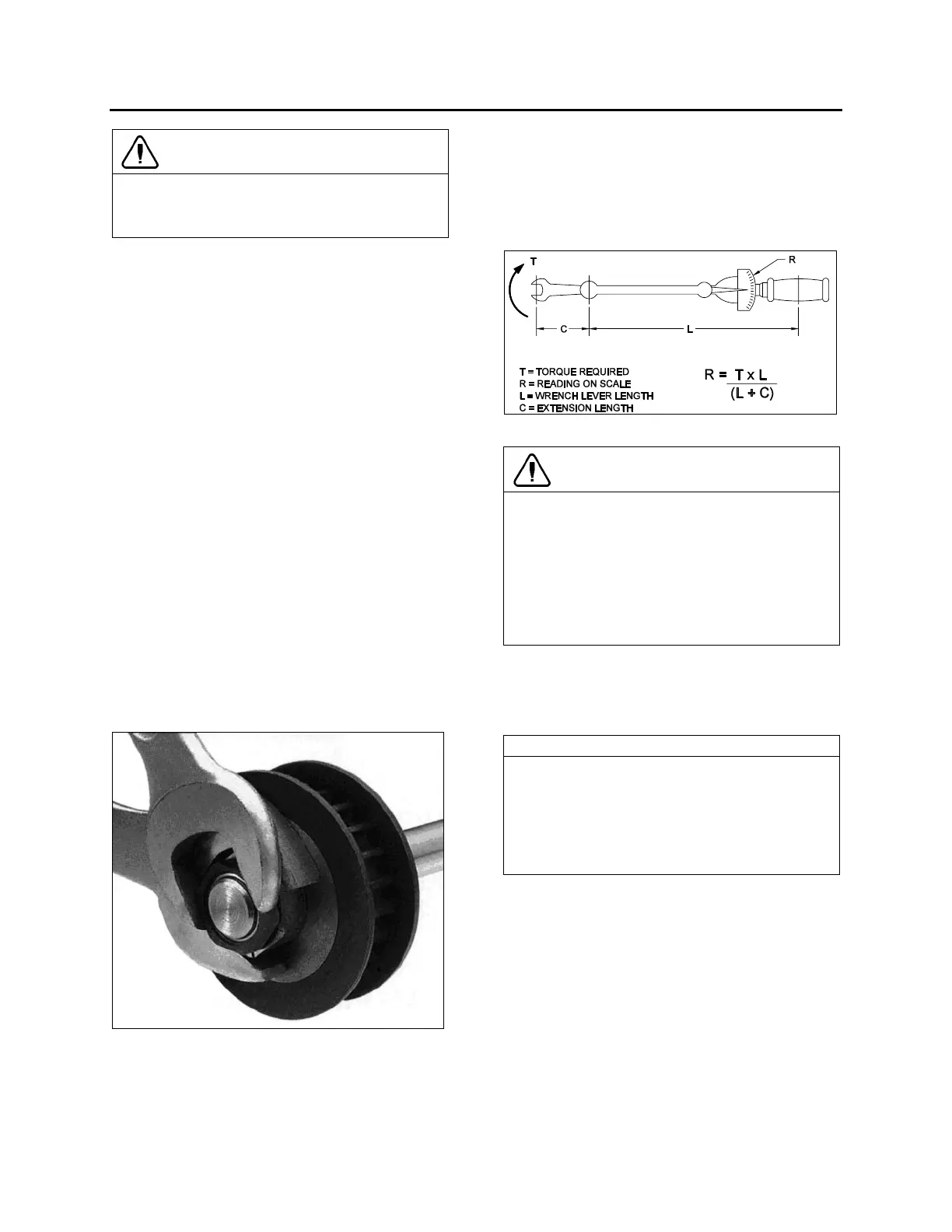

FIGURE 14 : KEYLESS BUSHING TIGHTENING

To tighten the keyless bushing, use a special

open-end wrench to retain the yellow part and

another wrench to tighten the black part. Figure

20 shows how to tighten the keyless bushing.

When tightening, make sure the pinion does not

move or rotate.

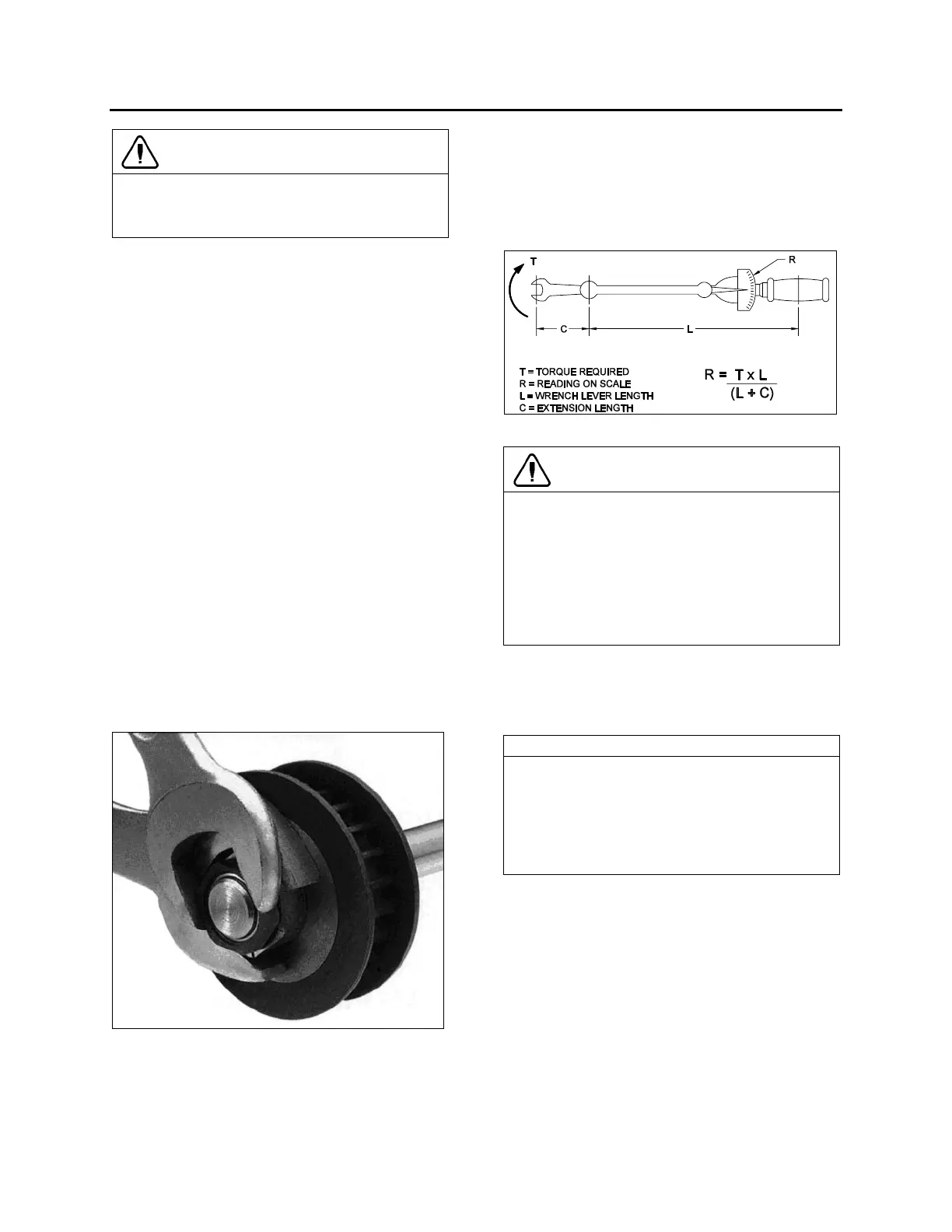

FIGURE 15 : TORQUE WRENCH FORMULA

CAUTION

Make sure all keyless bushings are tightened

to 125 lb-ft before moving the slide-out. A

lower torque value may cause the bushing to

slip on the shaft, and a higher torque value

may break the bushing. The torque may need

to be recalculated depending of the wrench

size. Refer to figure 15 for wrench size

compensation.

Take note that when the keyless bushing nut is

tightened, the pinion moves about 1/16" to 3/32"

toward the slide-out center.

NOTE

On the front slide-out, the driver side keyless

bushing is not accessible for tightening or

removal unless you remove the front left

wheel. If the slide-out has been removed, this

keyless bushing should be tightened before

reinstalling the slide-out.

Loading...

Loading...