Section 6: ELECTRICAL

PA1553

46

CAUTION

When replacing the alternator on the vehicle,

ensure that an alternator with the proper drive

ratio is used. Installation of an alternator with

any other drive ratio will result in severe and

costly damage to the alternator and engine.

7.8.4 Alternator Reassembly

Reassembly is the reverse of disassembly.

NOTE

When tightening the outside nut on the “DC”

output terminal, torque the nut to 30- 35 lbf-ft

(41-47 Nm). The lower nut should be

supported while doing so.

When reinstalling diodes, tighten to a torque of

9-11 lbf-ft (12-15 Nm).

7.8.5 Output check

When removed from the engine, the alternator

may be checked without circulating oil on a test

bench, providing the output is limited to 100

amperes or less. The alternator may be bench

tested without circulating oil at outputs

exceeding 100 amperes, as long as the period

of operation is limited to less than 15 seconds.

CAUTION

Operating the alternator at outputs greater

than 100 amperes without adequate oil

circulation for periods exceeding 15 seconds,

will cause the alternator to overheat, resulting

in damage to the winding and diodes.

If the alternator is to be operated at an output

greater than 100 amperes for longer than 15

seconds, circulating oil must be provided. SAE

30 engine oil must be applied to the connection

on the diode end cover at a pressure of 35 psi

and at a temperature of 60

o

F to 220

o

F (16

o

C to

104

o

C). This will provide an oil flow of about one

gallon per minute.

To check the alternator on a test bench, make

electrical connections as shown in figure 24.

Make sure the negative battery terminal is

connected to the alternator frame.

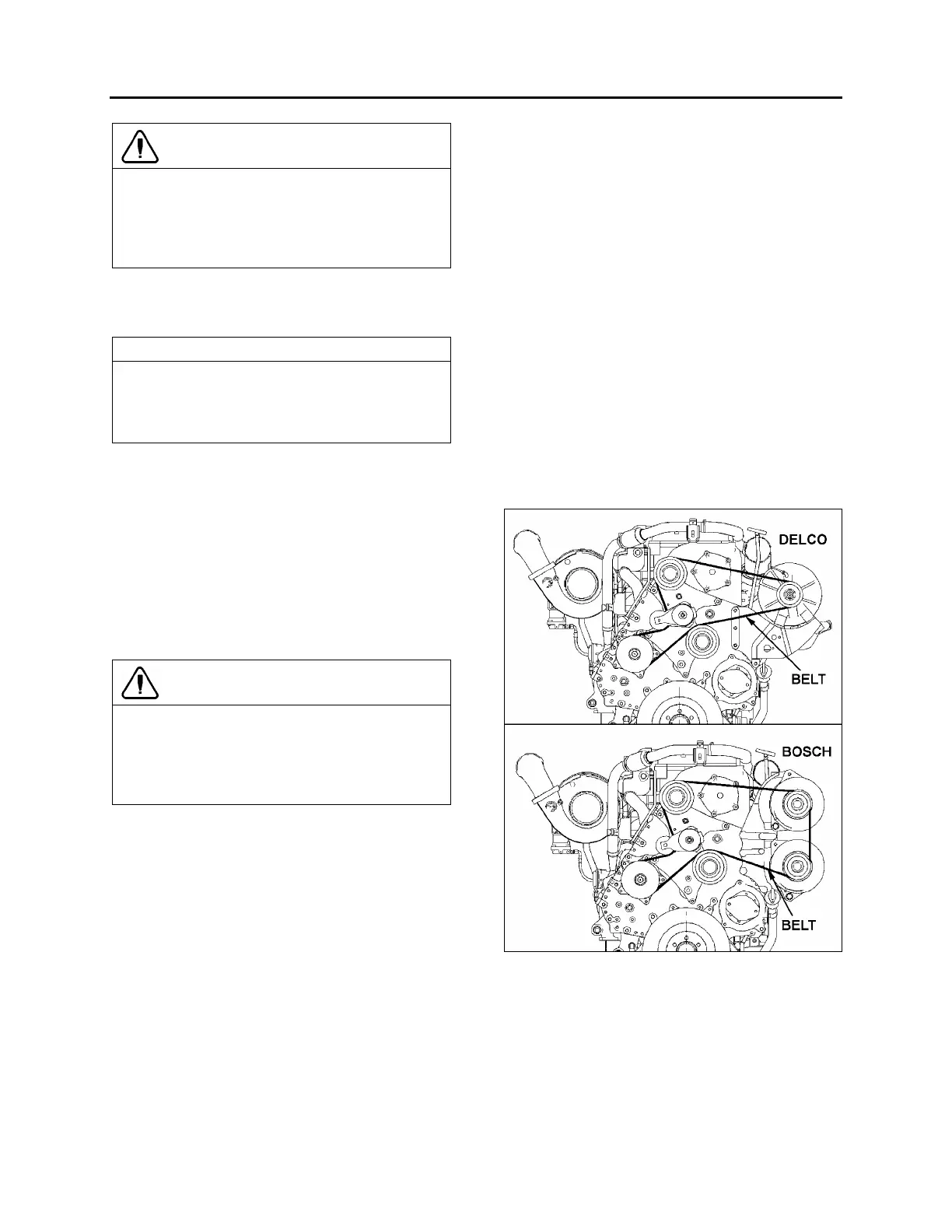

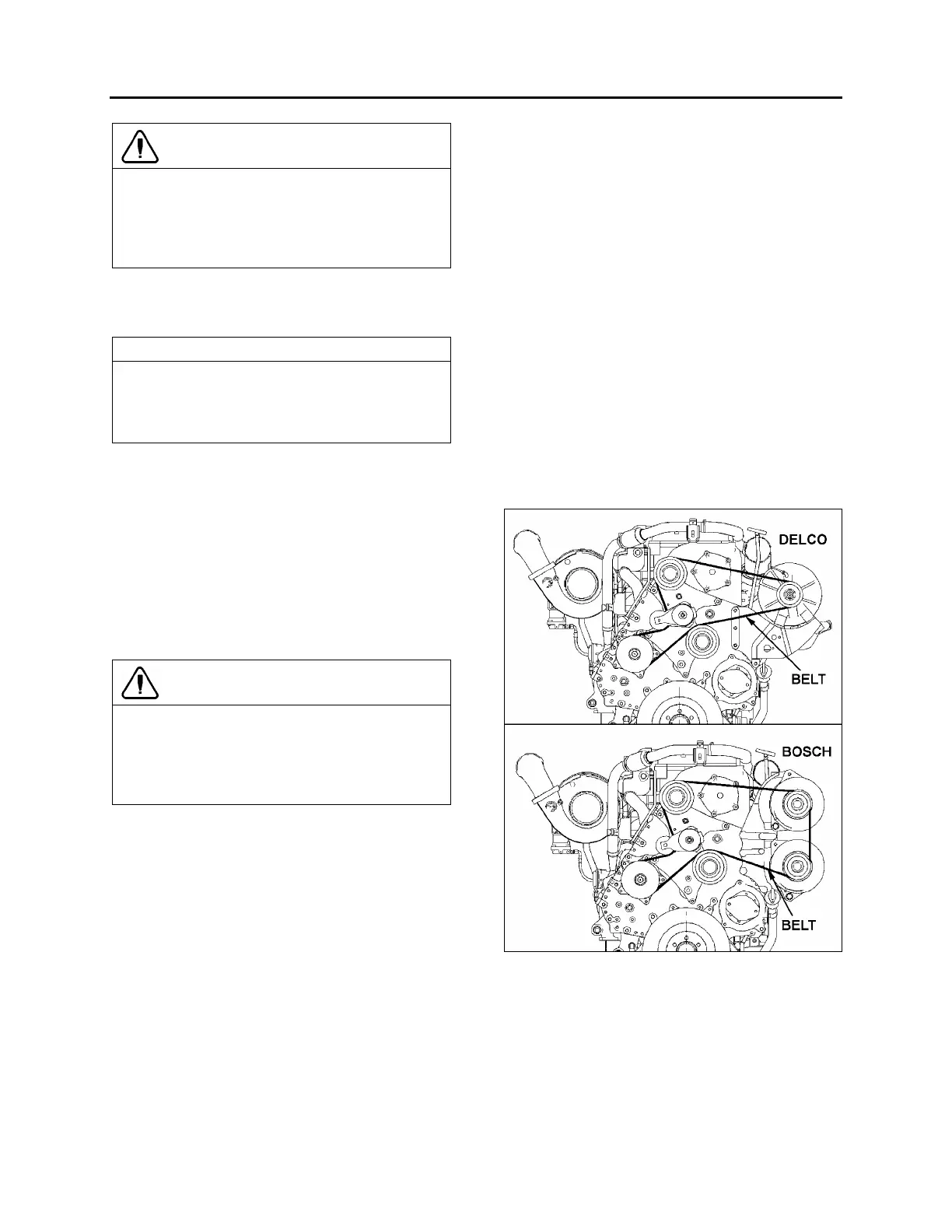

7.9 ALTERNATOR DRIVE BELT

Removal

1. Insert a ¾‘’ socket drive into the tensioning

arm opening (Fig. 31).

2. Twist the tensioning arm to slacken belt.

3. Remove belt.

Installation

Installation of the alternator drive belt is the

reverse of removal.

7.9.1 Adjustment

Correct belt tension is required to maximize belt

life. The tensioning arm maintains proper belt

tension, no adjustment is required.

Check for wear and proper tension every 6,250

miles (10 000 km) or twice a year, whichever

comes first.

FIGURE 31: ALTERNATOR DRIVE BELT 06509

8. VOLTAGE REGULATOR (DELCO)

The 24 volt regulator used with Delco alternator

is located in the engine compartment R.H. side

area.

The transistor regulator illustrated in figure 32 is

an assembly mainly consisting of diodes,

capacitors, resistors and transistors. These

Loading...

Loading...