38

5

Dura-Bright

®

surface treated

wheels cleaning

and maintenance

(continued)

d. Clean your Alcoa Dura-Bright

®

wheels using the above procedures as frequently

as required to maintain their appearance. Typical road soils, grime and brake dust trap

moisture, which can cause corrosion over a period of time. These must be removed

regularly. To assist in the removal of excessive dust, dirt and road grime, the use of warm,

high-pressure water with a mild detergent is recommended. The surface of Alcoa

Dura-Bright

®

wheels will be damaged, discolored or removed if abrasives, abrasive

brushes, steel wool, scouring pads or strong chemicals (such as acids or lye-based

products) are used to clean the wheel. DO NOT USE the Alcoa Aluminum Care System

on Dura-Bright

®

wheels at any time during their service life.

4. Once in service, Dura-Bright

®

wheels can become nicked or scratched by road

debris and/or mechanical damage. If this occurs, continue to follow the normal washing

and cleaning instructions provided above. The surface of an Alcoa Dura-Bright

®

wheel

is designed to limit cracking and peeling if nicked or scratched while in service.

5. Even as durable as Dura-Bright

®

wheels are, the mounting area can become

scratched, marred or discolored when mounted against another wheel, hub or drum.

The use of a wheel mounting surface guard, such as Alcoa DiscMates™, is highly

recommended. The use of the Alcoa Hub Cover System on Alcoa Dura-Bright

®

wheels

will also assist in limiting such damage and help maintain the appearance of your

Alcoa Dura-Bright

®

wheels.

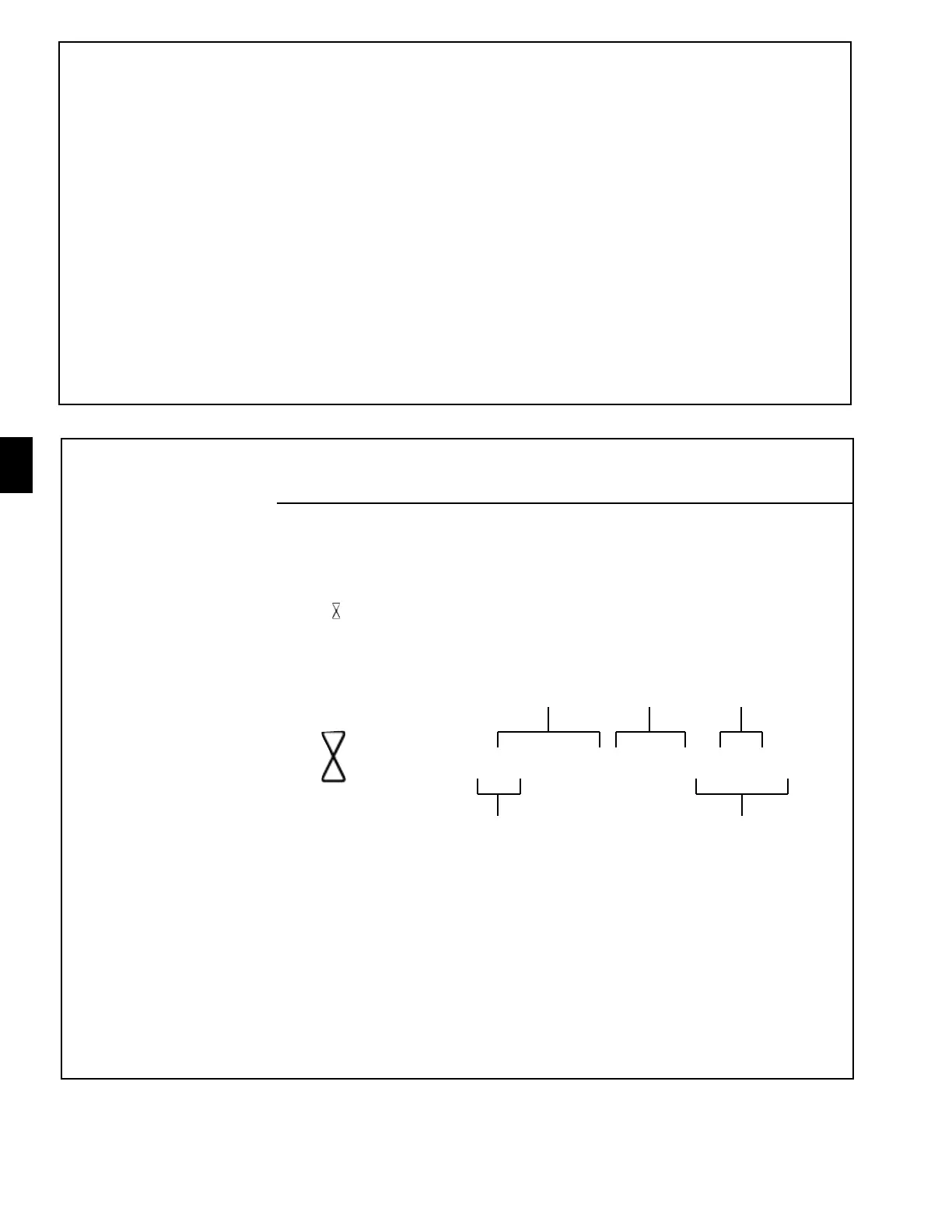

Identification

5-9

Alcoa wheel identification

Since 1977, all Alcoa aluminum disc wheels have been identified with a stamp that shows

the wheel load rating, maximum inflation pressure, date of manufacture, part number,

wheel description and DOT marking designation.

Prior to June 1996, all Alcoa heavy duty truck wheels had the Alcoa identification

symbol on the outside of the disc near the hand hole in line with the valve location.

This marking was phased out on heavy duty truck wheels manufactured after June 1996.

All Dura-Bright

®

surface treated wheels are designated by the letters “DB” following the

part number such as 883620DB.

Note: Dura-Bright

®

wheels produced after November 2002 have Alcoa wheel part

numbers ending with “DB” (earlier wheels have part numbers ending in a 4 or 7) with

bead seat diameters measured in 0.5-inch increments. Not all Alcoa wheels are available

with the Dura-Bright

®

surface treatment.

All Dura-Flange

®

wheels are designated by the letters “DF” following the part number

such as 883620DF.

Date of Manufacture

Month/Day/Year

(prior to 2000, some wheels

may have only Month/Year)

Wheel Description

ALCOA ® FORGED

MADE IN U.S.A.

Wheel Load Rating

(Pounds)

FMVSS 120

Designation

Maximum

Inflation Pressure

PART NO 883623

MAX LOAD 7300 LB. MAX PSI 120

082297

T—DOT

22.5X8.25 15° DC

Loading...

Loading...