Section 26: XLII SLIDE-OUT

PA1553

16

slide-out level. The distance between the top

of the horizontal member under the slide-out

and the slide-out under panel must be

21mm (13/16” approximately).

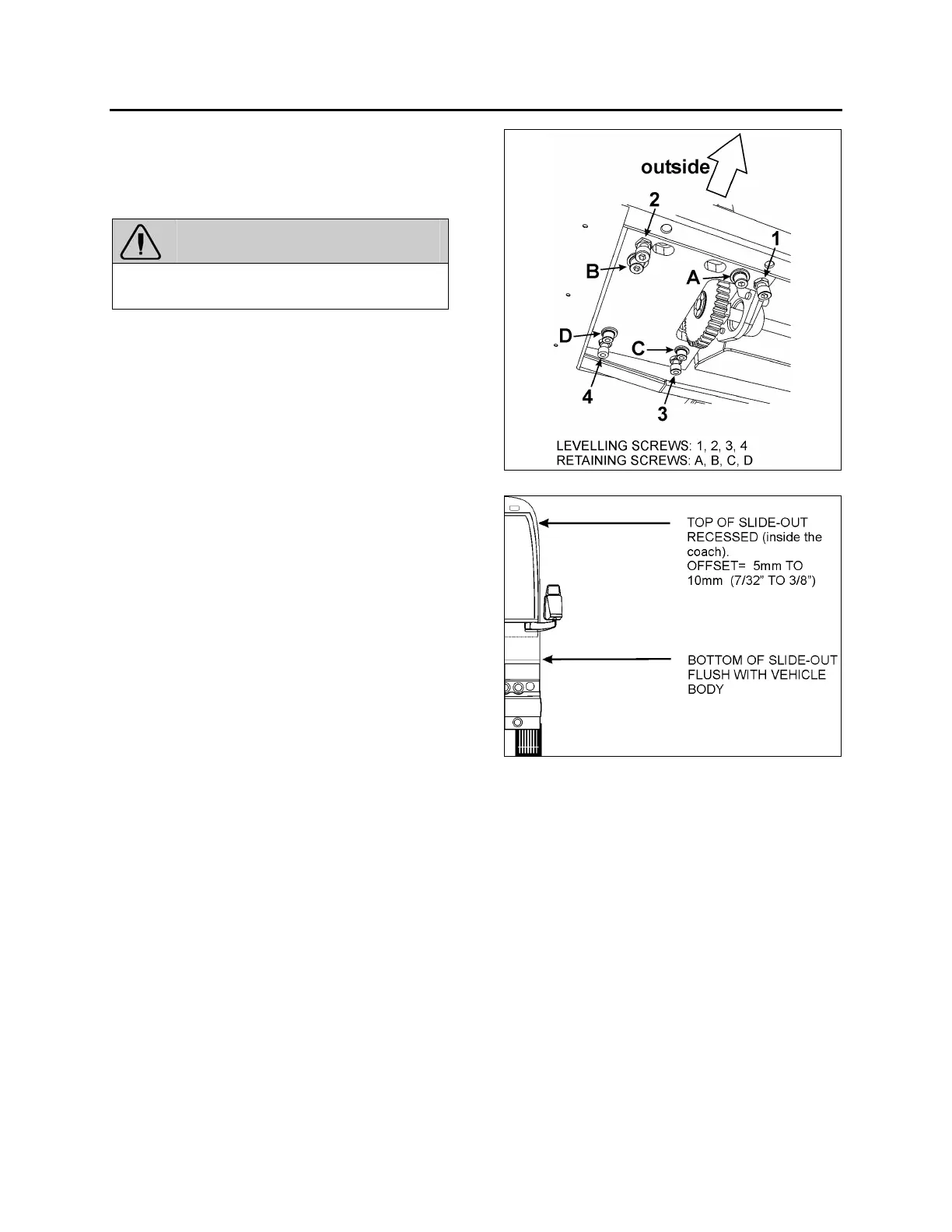

WARNING

Never unscrew completely retaining screw A,

B, C, D or the slide-out may tip inside.

To raise the linear bearing support plate, turn

levelling screw 1 & 2 clockwise. Slightly and

gradually, loosen the retaining screws A & B as

the support plate elevates, but keep the retaining

screws tighten.

To lower the linear bearing support plate, turn

screw 1 & 2 counterclockwise. As the support

plate goes down, maintain the retaining screw A

& B tighten.

4. Loosen retaining screws C & D. Unscrew

leveling screw 4. Now, the support plate

should be resting on levelling screw 1, 2 & 3.

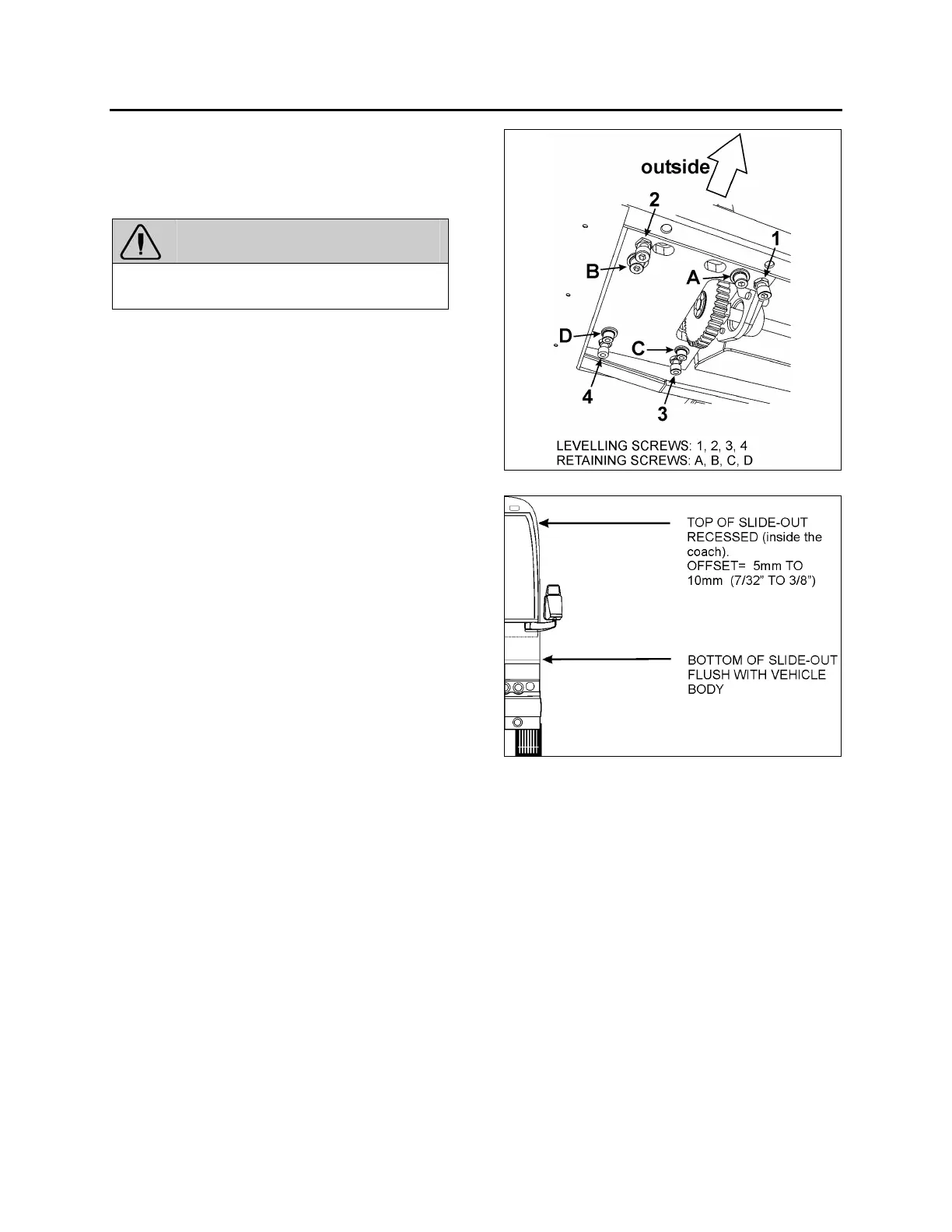

5. Using levelling screw 3, adjust the tilt in

order to have the top of the slide-out

recessed between 5mm and 10mm (7/32"

and 3/8") (see FIGURE 23).

6. When proper tilt is attained, tighten leveling

screw 4 so that it comes into contact with the

support plate.

7. Loosen slightly levelling screw 3 and then

tighten it so it is perfectly in contact with the

support plate. Make sure screws 1, 2, 3 & 4

are in contact with the support plate.

8. Loosen retaining screw A & B.

9. Using a crisscross pattern, tighten

progressively (3 rounds) the retaining screw

A, B, C & D to a torque of 50 ft-lb.

10. Assure that the levelling screw 1, 2, 3 & 4

are firmly leaning on the support plate and

then firmly tighten the jam nuts.

11. Verify that the tilt is still properly adjusted

(between 7/32" and 3/8").

FIGURE 22 : SLIDE-OUT LEVELING

FIGURE 23: TILT ADJUSTMENT

12 RAIL

Rail and linear bearing system provide precise

frictionless linear movement together with high

load carrying capacity and high stiffness. These

standardized equipments are fully

interchangeable.

To prevent corrosion, an electrolytic black film

treatment is performed to the rail. Do not strike

the rail with metal tools, this could damage the

treatment.

After the rail is mounted to the slide-out base, a

cap is used to cover the bolt hole to prevent

foreign matters from clogging up the hole or from

entering into the ball slide. The cap for the bolt

hole is made of synthetic resin which is superb

in its resistance to oil and wear.

Loading...

Loading...