Section 26: XLII SLIDE-OUT

PA1553

17

12.1 MAINTENANCE

Check that all the caps for the bolt hole are

present. Missing caps must be replaced. To

insert a cap into the rail bolt hole, use a flat tool.

Pound the cap gradually until its height becomes

flush with the rail top face.

Clean accumulated dirt from the rails with a soft

cloth.

12.2 REPLACEMENT

1. Remove the slide-out from the vehicle

(removal must be performed according to

the Slide-Out Removal Procedure. Ask to

your Prevost service representative).

2. Remove the bolt hole cap covers. To do so,

pierce a hole in the center and hook them

out. They will not be reusable.

3. Remove the rail mounting bolts.

4. Wipe off the rust preventive oil applied to the

new rail. Remove burrs and small bumps on

the slide-out mounting face with an oilstone.

5. Carefully place the rail on the bed on its

mounting face.

NOTE

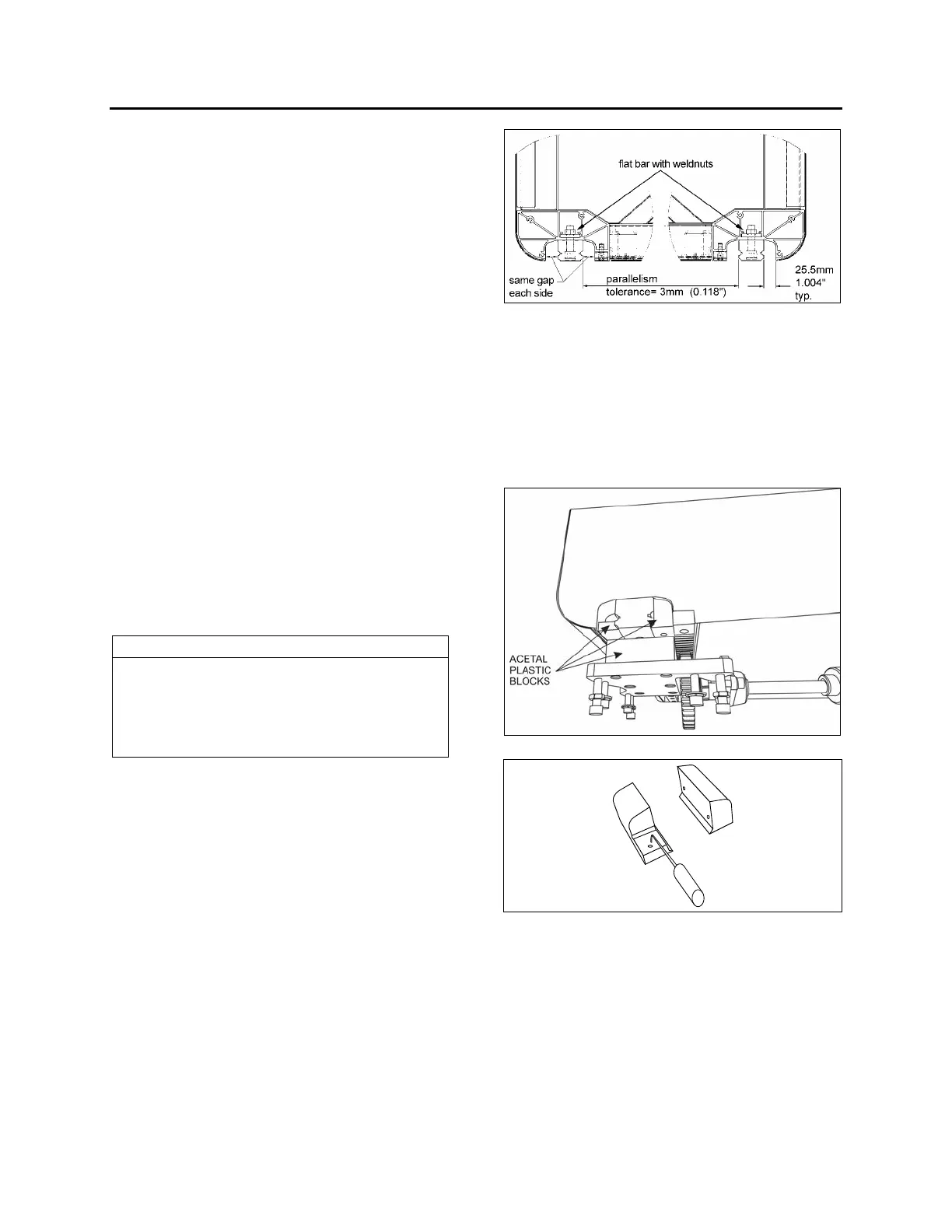

The rail is bolted to a flat bar on which

weldnuts are mounted. The flat bar is inserted

in the slide-out lower body extrusion and can

be removed through the end cap (FIGURE

24).

6. Adjust the flat bar position to align the

weldnuts with the rail mounting holes.

7. Temporarily tighten the bolts.

8. Adjust the rail position with as per FIGURE

24. For each rail, make sure the gap is the

same both side of the rail.

9. For final tightening of the bolts, tighten on

either end of the rail and then start to the

other end. Tighten to a torque of 95 ft-lbf.

Use blue Loctite ™ on threads.

10. Cap the bolt holes.

FIGURE 24 : RAIL POSITIONING

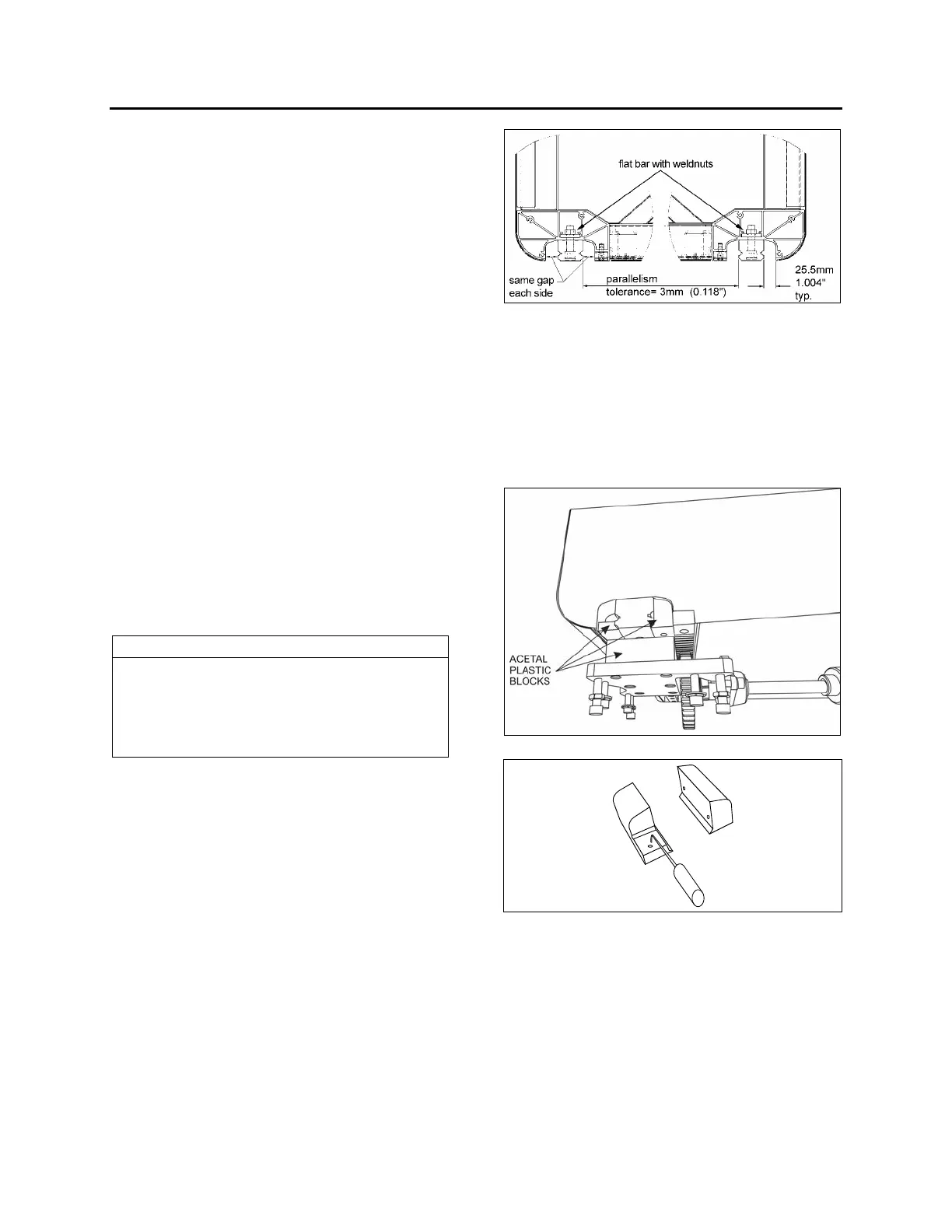

13 ACETAL PLASTIC BLOCKS

Three different acetal plastic blocks are installed

next to each linear bearing to prevent dirt and

foreign matter from entering inside the vehicle.

They also serve as bearing surface for:

1. The inflatable seal each side of the rail.

2. The “in limit” stoppers.

FIGURE 25: ACETAL PLASTIC BLOCKS

FIGURE 26: REMOVE THE UPPER ACETAL PLASTIC

BLOCKS WITH A PICKING TOOL

13.1 REMOVAL / INSTALLATION

1. Gain access to the linear bearing support

plate.

2. From under the support plate, remove the

acetal plastic block mounting screws (see

the oblong holes on figure 22).

Loading...

Loading...