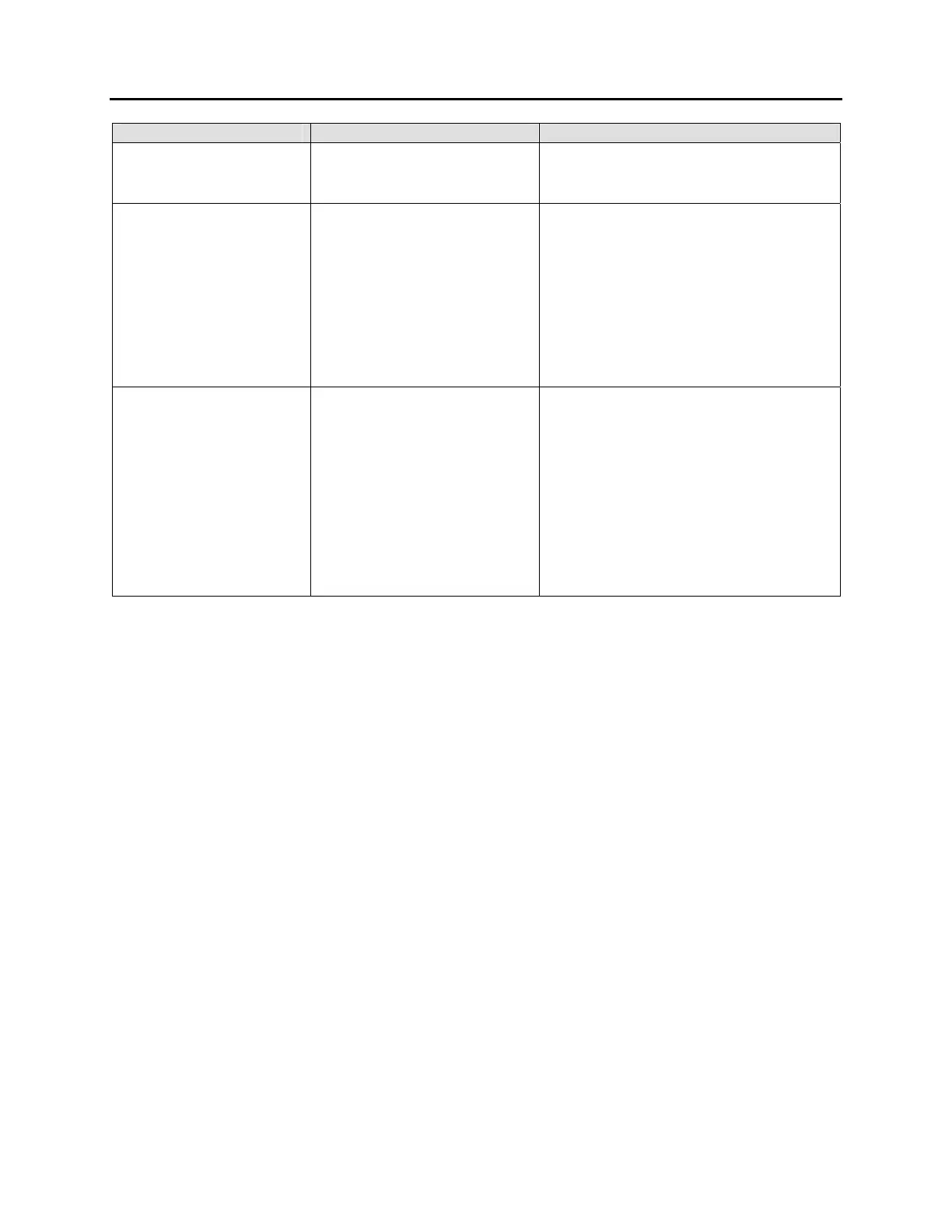

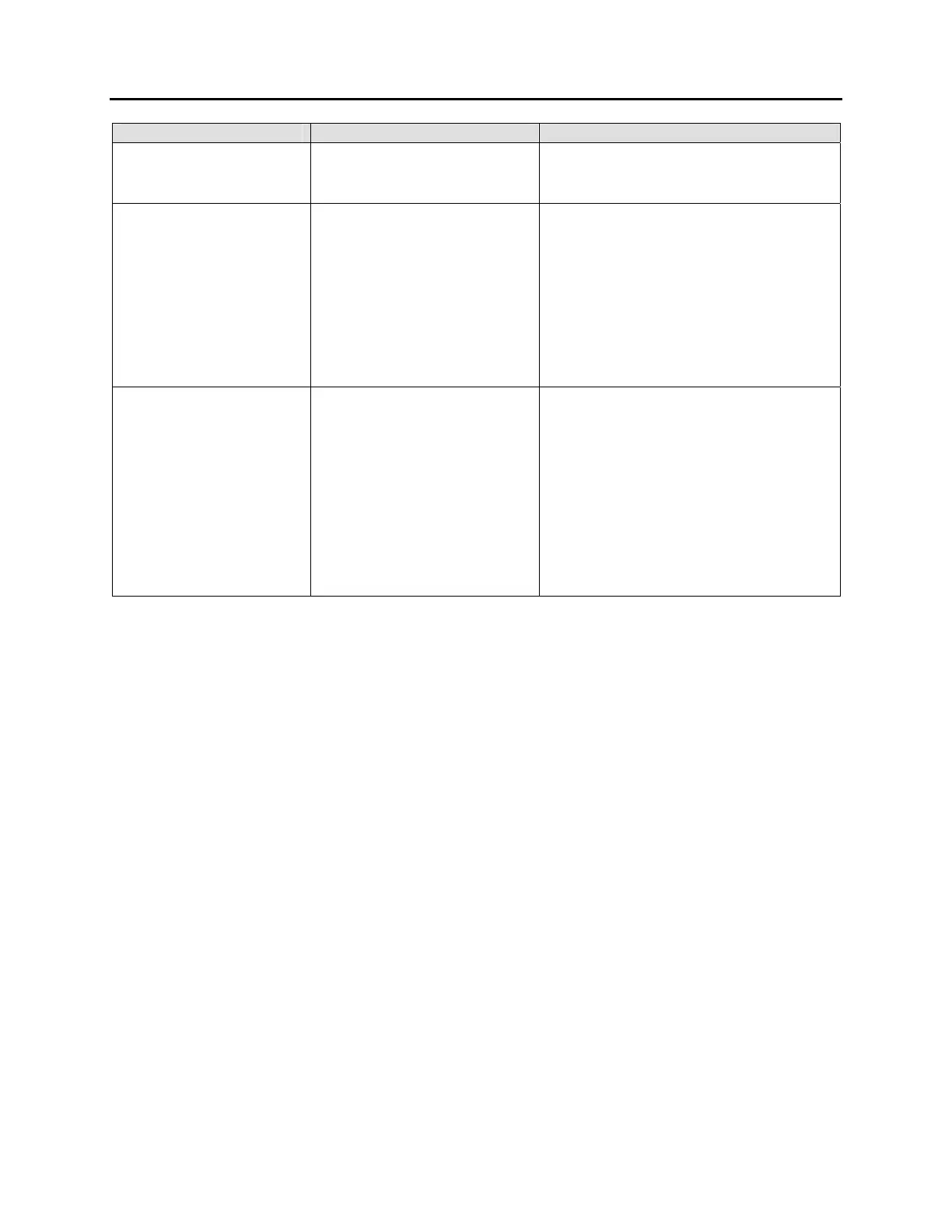

Section 22: HEATING AND AIR CONDITIONING

PA1553

13

Problem/Symptom Probable Causes Actions

2. Check / reset circuit breaker CB7

3. Check / replace fuse F12

The A/C compressor clutch

does not engage

Module A52 is not powered or is

faulty

1. Check the SYSTEM DIAGNOSTIC menu

of the message center display (MCD).

Select FAULT DIAGNOSTIC and

ELECTRICAL SYSTEM. The message

“Voltage Module A52, Value too Low,

Active” confirms a power problem on the

module

2. Check / reset circuit breaker CB7

3. Check / replace fuse F65

Evaporator fan not

functioning

Circuit breaker CB4 tripped

Module A54 is not powered or is

faulty

Faulty brushes

1. Check / reset circuit breaker CB4

2. Check the SYSTEM DIAGNOSTIC menu

of the message center display (MCD).

Select FAULT DIAGNOSTIC and

ELECTRICAL SYSTEM. The message

“Voltage Module A54, Value too Low,

Active” confirms a power problem on the

module

3. Check / reset circuit breaker CB4

4. Check / replace fuse F67 , F68

8. CENTRAL HVAC SYSTEM - AIR

CONDITIONING

The schematic of Figure 16 shows the central A/C

system and its components. The central system is

equipped with a 6 cylinder, 05G-134A Carrier

compressor with an air conditioning capacity of

7½ tons. The receiver tank and filter dryer are

mounted inside the condenser compartment.

XLII Converted vehicles may be supplied with a

central or small A/C system (Fig. 16 and 40). For

vehicles equipped with a small A/C system, refer

to paragraph 10: SMALL HVAC SYSTEM – AIR

CONDITIONING COMPONENTS further in this

section.

8.1 A/C CYCLE

Refrigeration may be defined as "the transfer of

heat from a place where it is not wanted to a

place where it is unobjectionable". Components

required for a closed circuit refrigeration system

are shown in Figures 16 and 41.

The air conditioning system used on XLII series

vehicle is of the "Closed" type using "R-134a".

1. The refrigerant flowing to the compressor is

compressed to high pressure and reaches a

temperature higher than the surrounding

air. It is passed through the air-cooled fins

and tubes of the condenser causing the hot,

high pressure gas to be condensed into a

liquid form.

2. The liquid refrigerant flows to the receiver

tank, then back to the condenser sub-

cooler. It leaves the condenser and passes

through a filter dryer where moisture, acids

and dirt are removed and then through a

moisture indicator which indicates if any

moisture is present in the system.

3. By its own pressure, the liquid refrigerant

flows through a thermal expansion valve

where the pressure drop causes the

refrigerant to vaporize in a vapor-liquid state

at a low temperature pressure.

4. The cold low pressure refrigerant passes

through the main and the driver’s

evaporator coils which absorbs heat from

the air passing over the fins and tubes, and

changes into gas. In this form, the

refrigerant is drawn into the compressor to

repeat the air conditioning cycle.

Loading...

Loading...