Section 22: HEATING AND AIR CONDITIONING

PA1553

31

vaporization of the refrigerant. The gas

continues along in the evaporator and remains

at the same pressure. However, its temperature

increases due to the continued absorption of

heat from the surrounding atmosphere. The

degree to which the gas refrigerant is

superheated is related to the amount of

refrigerant being fed to the evaporator and the

load to which the evaporator is exposed.

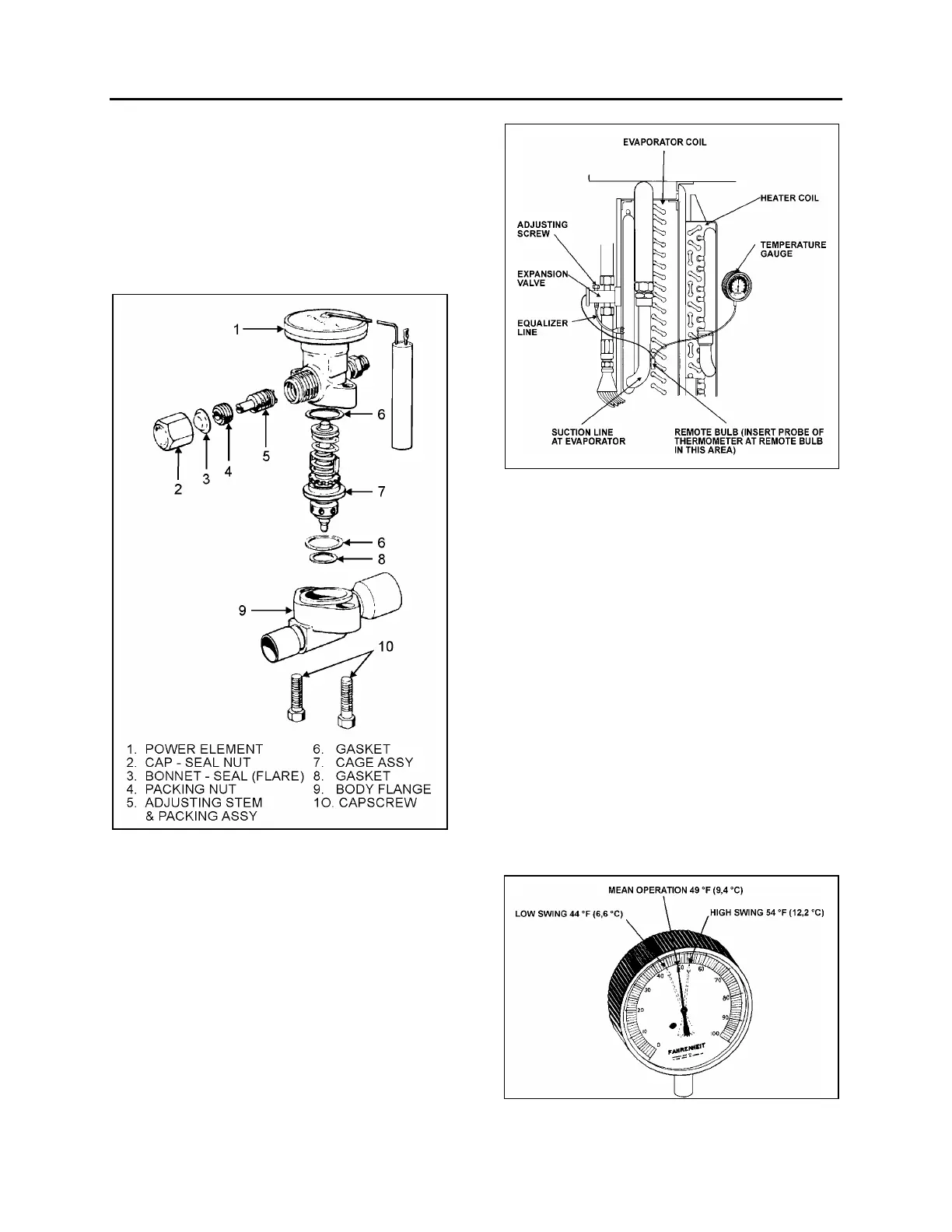

FIGURE 34: EXPANSION VALVE 22045

Superheat Adjustment

The starting method of adjusting the superheat

is to unscrew completely the main evaporator

expansion valve adjusting screw, then screw in

13 turns clockwise for 134A (Fig. 35).

Afterwards, the following procedure should be

followed:

1. Operate vehicle for at least one-half hour at

fast idle with temperature control set at 82

o

F

(27,7

o

C), Then set temperature to minimum

to keep the compressor on 6 cylinders.

FIGURE 35: SUPERHEAT ADJUSTMENT INSTALLATION22046

2. Install pressure gauge at the evaporator

suction header. You may install the

pressure gauge at compressor suction, but

then add 3 psi to reading.

3. Install a remote reading thermometer to the

evaporator outlet line near the existing

remote bulb (Fig. 35).

4. Apply thermostatic tape around the bulb

and evaporator outlet line to get a true

reading of the line temperature.

5. Block condenser if necessary to keep

pressure over 150 psi.

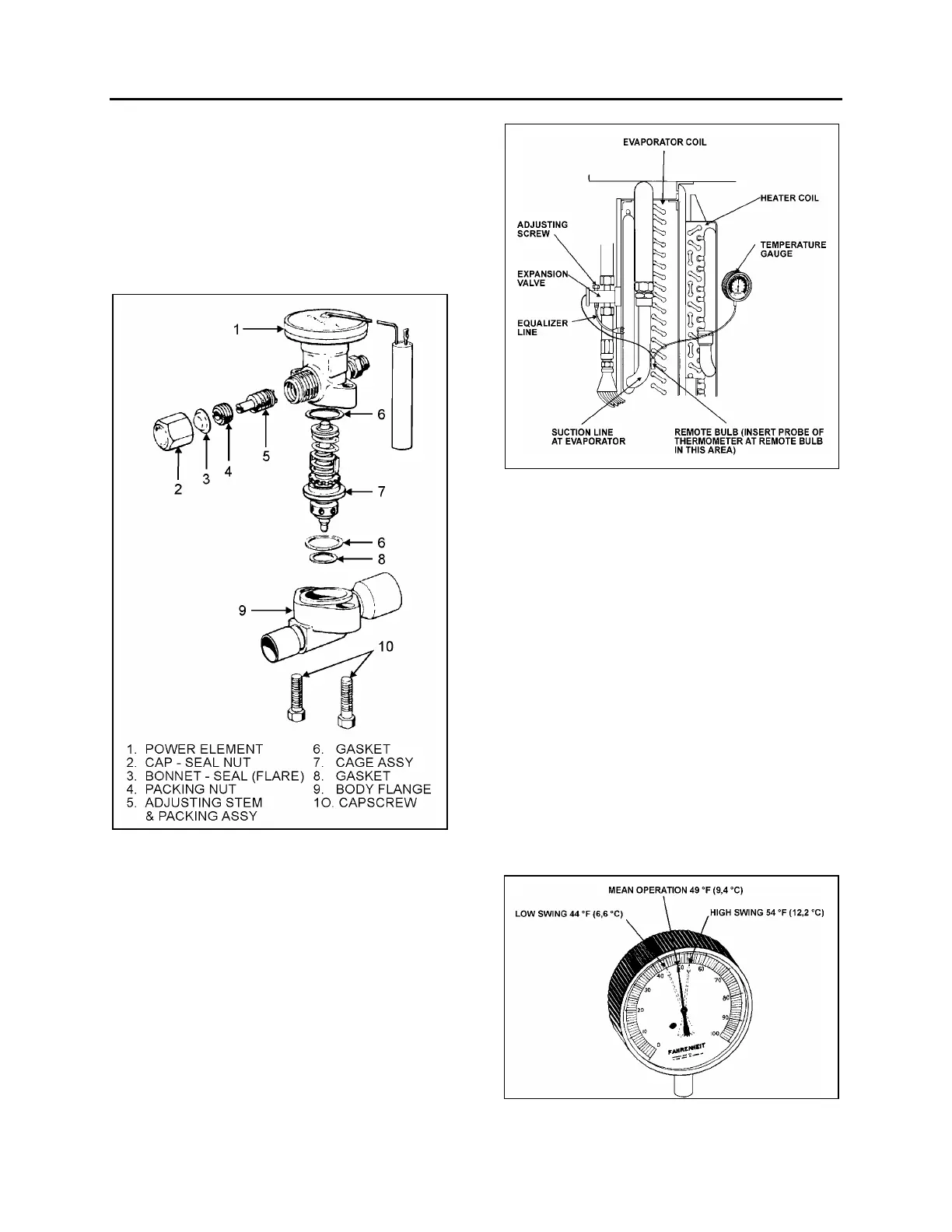

6. Check approximately 5 readings of

pressure at 2-minute intervals and convert

to temperature using the temperatures &

pressures table (page 31). Likewise check

the temperature reading at the remote bulb

at the same 2-minute intervals and record

the low and high swing readings of the

needle (refer to Fig. 36).

FIGURE 36: HIGH & LOW SWING TEMPERATURE AT

REMOTE BULB

22047

Loading...

Loading...