Section 26: XLII SLIDE-OUT

PA1553

22

sealant on the structure surface where the

inflatable seal will be placed. Wait until the

product is dry before proceeding.

7. Install the inflatable seal on the structure,

placing it as close as possible from the

exterior side of the structure. Position the air

inlet first. Then remove locally the inflatable

seal adhesive tape protection, and press the

upper corners on the structure and hold

them in place for 90 to 120 seconds. Install

the lower corners next, then the straight

section. Press the straight inflatable seal

sections on the structure for at least 15

seconds. Use a small roller to ensure a good

adhesive contact on the structure.

8. Seal the gap between the inflatable seal and

the exterior panels and the gap between the

glasses and the fiberglass panels with

appropriate sealant. Wait until the product is

dry before proceeding. Remove excess

sealant with appropriate cleaner.

9. Replace the bushing and plug the pneumatic

tubing on the inflatable seal air inlet

(FIGURE 31).

14.3.4 Slide-out 2" inside retraction

1. For both sides of the slide-out, remove the 2

upper acetal plastic blocks shown on

FIGURE 26 (refer to section 13).

2. Manually deflate the seal completely by

turning the relieving shut-off valve clockwise

(FIGURE 29). Make sure the pressure

indicator reading is "0 psi".

3. Turn the ignition to the off position. Using

the manual override procedure (section 18),

extend the slide-out a few inches so the

exterior extrusion screws located on the top

of the slide-out are accessible from outside

(figure 7).

4. Using a knife cut the sealant between the

extrusion and the roof (figure 7). Unscrew

and remove the central exterior extrusion

screws and the two end extrusion screws.

CAUTION

Do not use the slide-out handheld control to

move the slide-out 2" inside the vehicle,

because the limits are not recognized over the

closed position. The slide-out will not stop and

damage may occur.

5. Using the manual override procedure, move

the slide-out 2" inside the vehicle, so the

seal is accessible from outside (FIGURE

32).

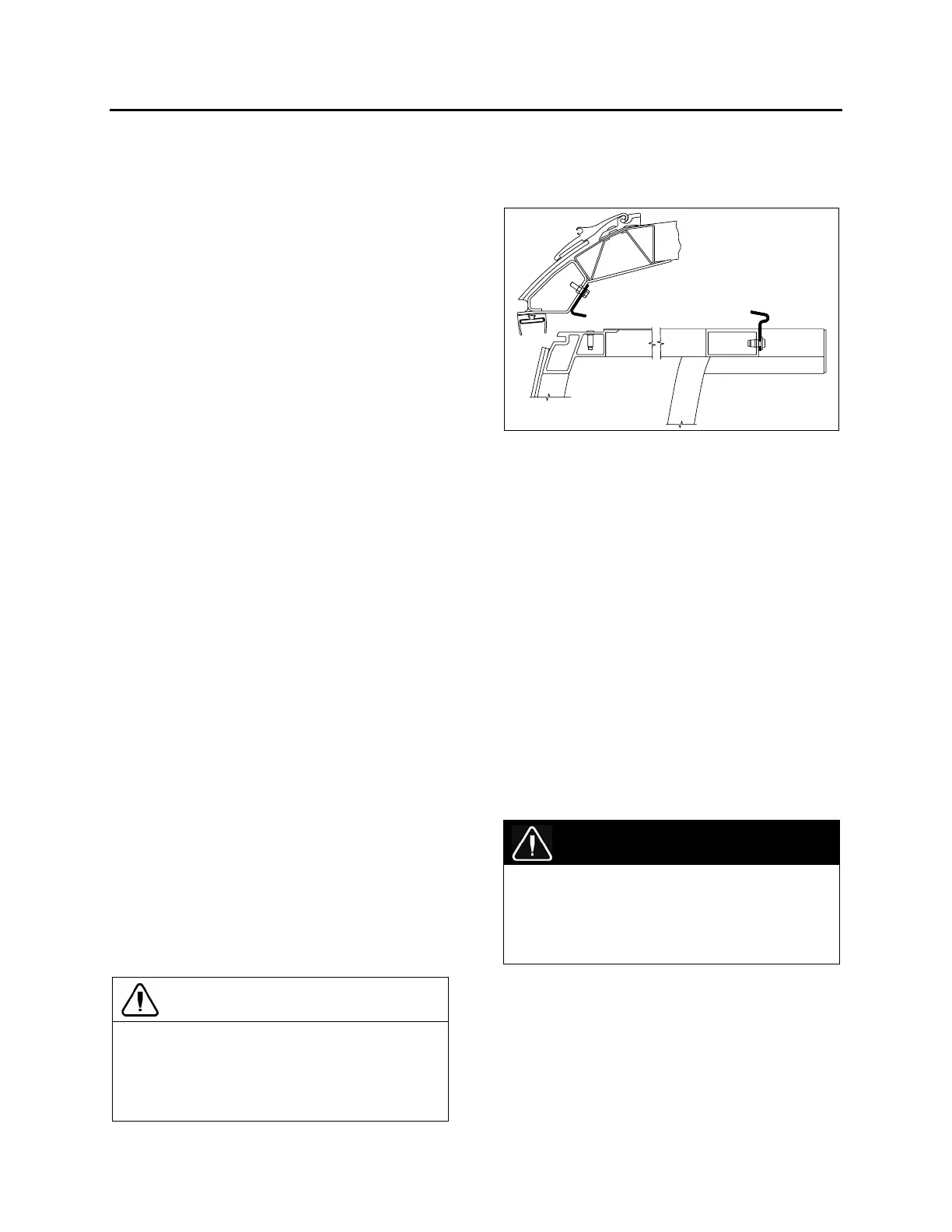

FIGURE 32: SLIDE-OUT 2" INSIDE – UPPER PART

6. Once completed, use the manual override

procedure to extend the slide-out to reinstall

the exterior extrusion. Apply appropriate

sealant on the exterior extrusion screws and

between the extrusion, the roof and the

edges to prevent water infiltration (FIGURE

32).

7. Reinstall the acetal plastics blocks.

8. Using the manual override procedure,

retract the slide-out to its closed position.

9. Finally, the seal can be re-inflated by turning

the shut-off valve handle counterclockwise.

Check the pressure gage on the inflatable

seal regulator to see if the pressure is

increasing to 10 psi.

15 SLIDE-OUT ELECTRICAL

SYSTEM

DANGER

Never modify the slide-out electrical wiring

without the Prevost Car approval. Any

modifications may cause an unexpected slide-

out action and could result in personal

injuries.

The multiplexed slide-out electrical system is

mainly composed of the Master ID module, the

CECM module, the VEC module and two I/O-B

modules.

Each slide-out has its own I/O-B module and two

power relays. The I/O-B modules analyze the

input signal conditions and activate outputs like

the pneumatic valves, the retracting or extending

Loading...

Loading...