Section 26: XLII SLIDE-OUT

PA1553

43

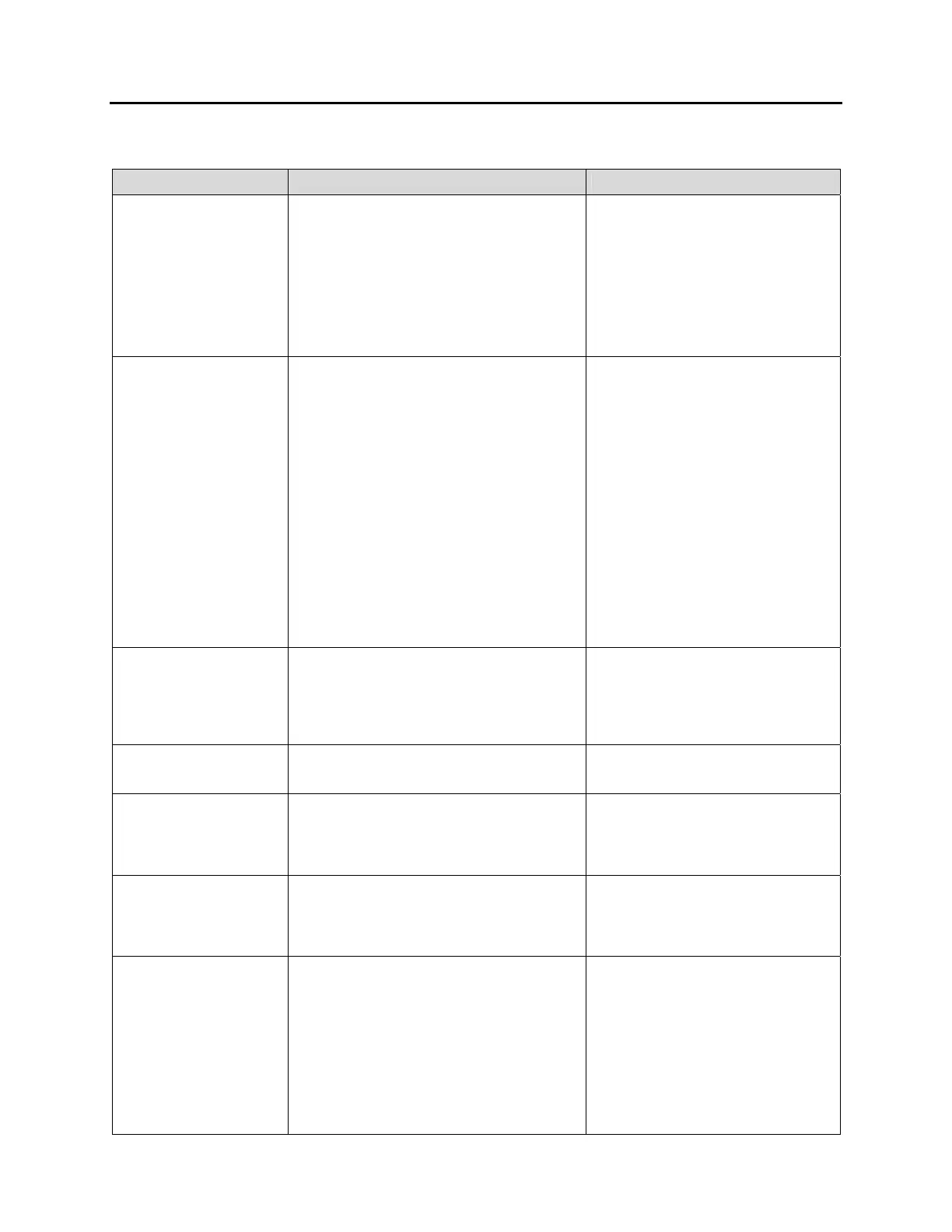

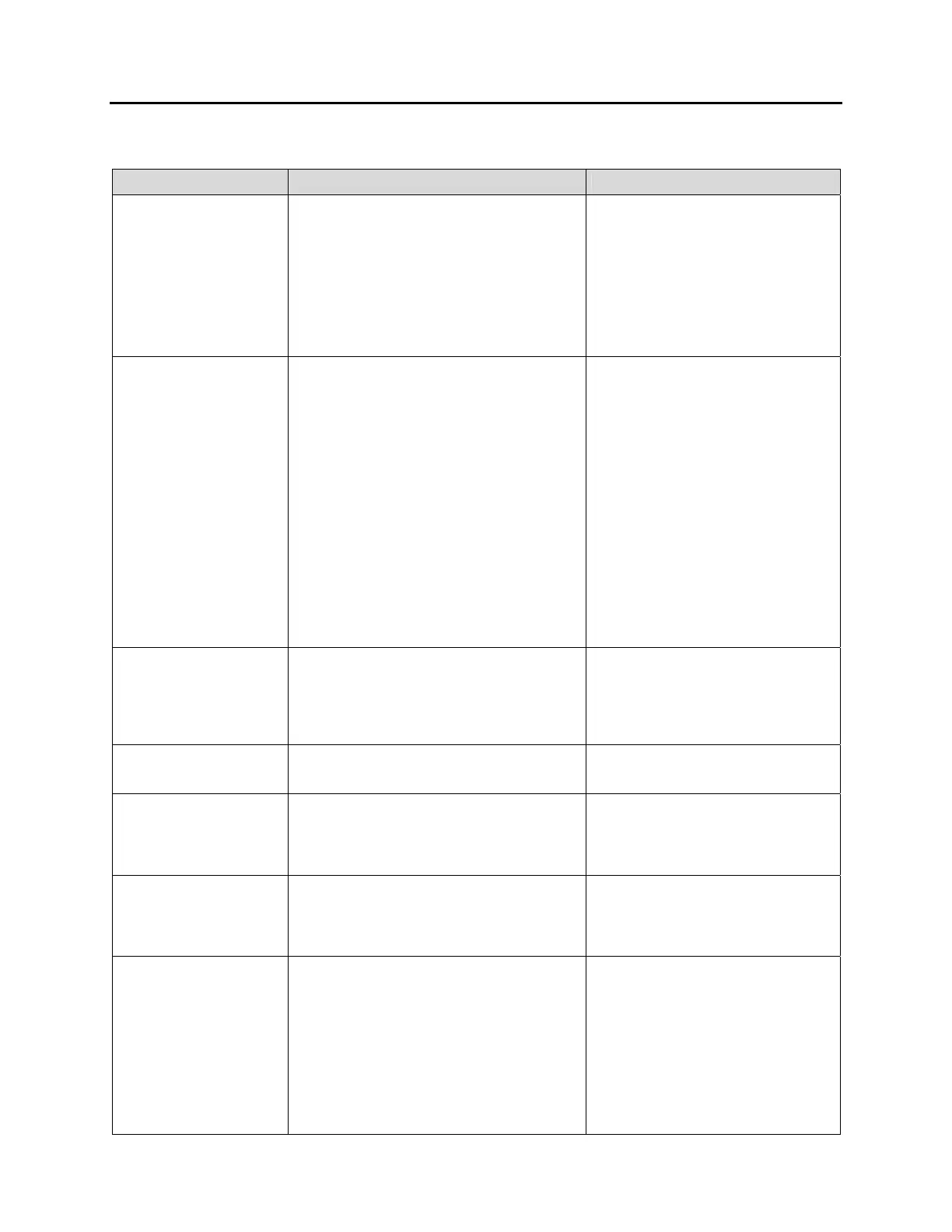

20.3 TROUBLESHOOTING - MECHANICAL COMPONENTS

PROBLEM CAUSE CORRECTIVE ACTION

Slide-out does not retract

or extend when

depressing the control

switch.

A. Electrical motor failure;

B. Speed reduction gearbox failure;

C. Security pin still engaged in receptacle;

A. Replace motor.

B. Inspect gearbox components,

particularly: bronze wheel or first

reduction stage output shaft.

Replace damaged components.

C. Disengage pin and check if air

cylinder is damaged.

Slide-out is not straight

once retracted or during

retracting or extending

operation.

A. Broken rack tooth;

B. Faulty rack attachment;

C. Faulty shaft key at speed reduction

gearbox or jaw coupling;

D. Pinion keyless bushing slipping;

E. Shaft breaking;

F. Flange bearing attachment loosen;

A. Replace rack.

B. Tighten mounting bolts, apply

proper torque and use Loctite

threadlocker (replace rack if

necessary).

C. Replace key or component having

a damaged keyway.

D. Realign slide-out and apply proper

torque to keyless bushing.

E. Replace shaft.

F. Reposition shaft and tighten

flange bearing mounting bolts.

Slide-out moves out

slightly when vehicle is

traveling.

A. Lower "in limit" stoppers are not leaning

against the structure at the moment when

the "in limit" sensor detects the magnet;

A. Adjust the sensor position in order

to have contact of the stoppers

against the structure at the time

when the system stops the slide-out

retraction.

Slide-out moves when

vehicle is moving.

A. Inflatable seal not inflated A. Check seal condition and seal air

supply system.

Slide-out retracts or

extends difficultly.

A. Foreign matters accumulated in the linear

bearing;

A. Inspect the linear bearing end

seals to see if they are in good

condition. If not, replace the end

seals and clean the inside of linear

bearing.

Slide-out oscillates

vertically when retracting

or extending

A. Linear bearing balls hardened due to a too

heavy load;

B. Linear bearing mounting bolts loosen;

A. If balls clearance is excessive,

replace linear bearing.

B. Tighten mounting bolts.

Slide-out vibrating or noisy

when extending or

retracting

A. Acetal plastic block rubbing against the

slide-out structure;

B. Worn-out anti-friction coating on wiper

seal around slide-out;

C. Lower acetal plastic block rubbing

against rail;

A. Realign acetal plastic block.

B. Replace wiper seal.

C. Remove lower acetal plastic block

and machine down 1mm (0.039").

Loading...

Loading...