Section 6: ELECTRICAL

PA1553

54

High Beam Adjustment

1. Turn ON high beam lights.

2. Press ALIGN TO LAMP and move aligner in

front of first beam.

3. Adjust aligner height (move aligner

sideways if needed) so that XX appears in

the aligner sight. Lock aligner side handle.

4. Open Hoopy 100 aligner door.

5. Press AIM LAMP down; press a second

time so that HIGH ADJUST appears in the

sight. Arrows indicate in which direction to

adjust the beam using the vertical and

horizontal adjustment screws. Perform this

adjustment until XX appears in the sight.

6. Aligner will reset after 5 minutes.

7. Repeat for other high beam light.

8. Store equipment away in a safe place.

If proper mechanical equipment is not

available, perform adjustments as

described hereafter:

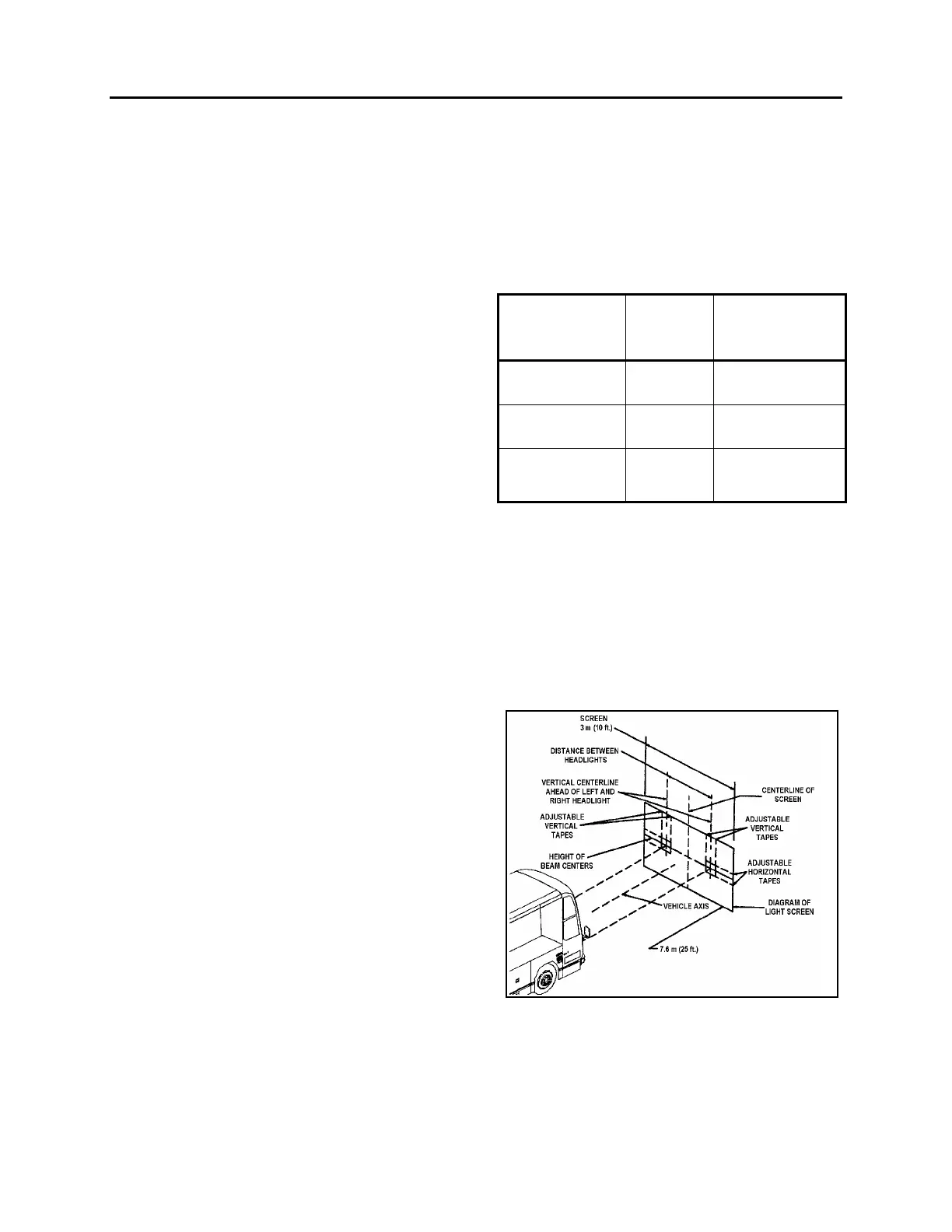

1. Headlight aiming and inspection can be

accomplished by visual means. This is done

on a screen located at a distance of 25 feet

(7,6 m) of the headlights. It should be of

adequate size with a matte-white surface

well shaded from extraneous light and

properly adjusted to the floor area on which

the vehicle stands. Provisions should be

made for moving the screen or its vertical

centerline so that it can be aligned with the

vehicle axis. In addition to the vertical

centerline, the screen should be provided

with four laterally adjustable vertical tapes

and two vertically adjustable horizontal

tapes.

2. The four movable vertical tapes should be

located on the screen at the left and right

limits called for in the specification with

reference to centerlines ahead of each

headlight assembly.

3. The headlight centerlines shall be spaced

either side of the fixed centerline on the

screen by ½ the lateral distance between

the light source centers of the pertinent

headlights. The horizontal tapes should be

located on the screen at the upper and

lower limits called for in the specification

with reference to the height of beam centers

and the plane on which the vehicle rests, not

the floor on which the screen rests (Fig. 49).

4. The nominal vertical aim position on lower

beam headlights shall be adjusted based on

the headlight mounting height, from the

ground to the light source center of the

headlight, according to table1.

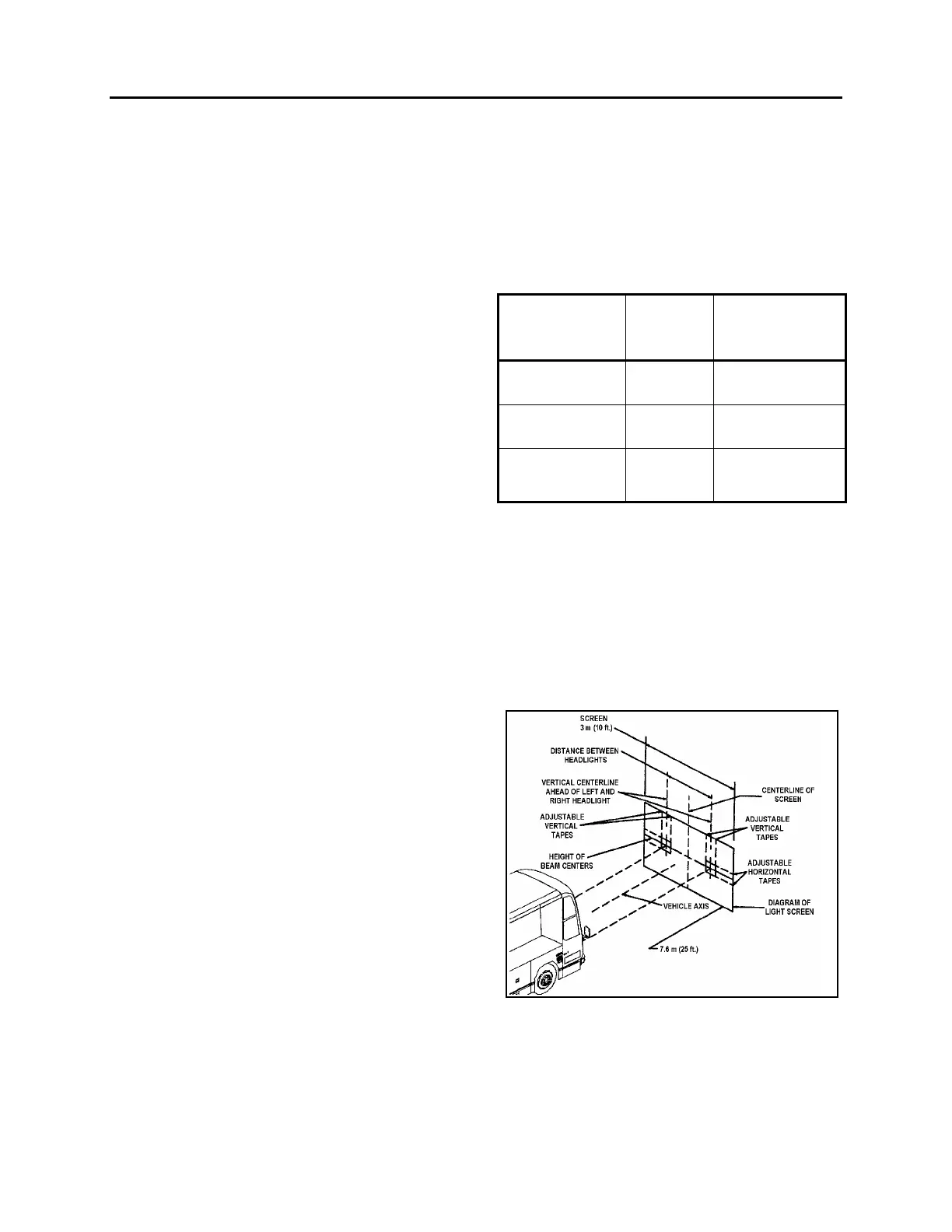

TABLE 1 – VERTICAL BEAM AIM GUIDELINES

Headlight

(centerline)

Mounting Height

Nominal

Vertical

Aim

Aim Inspection

Limits for Vertical

Aim

56 to 90 cm (22 to

36 inch)

0 Vertical 10 cm (4 inch) up to

10 cm ( 4 inch) down

90 to 120 cm (36 to

48 inch)

5 cm (2 inch)

down

5 cm (2 inch) up to 15

cm (6 inch) down

120 to 140 cm (48 to

54 inch)

6.4 cm (4

inch) down

4 cm (1.5 inch) up to

16.5 cm (6.5 inch)

down

5. High beam headlights are aimed so that the

center of the high-intensity zone is located

at the horizontal and straight ahead

vertically (Fig. 50).

6. Low beam headlights are aimed so that the

top edge (the cutoff) of the high-intensity

zone is at the vertical location as per Table

1 and the left edge of the high-intensity zone

is at the vertical centerline of the headlight

(Fig. 51).

FIGURE 49: ALIGNMENT OF HEADLIGHT AIMING

SCREEN

06502

Loading...

Loading...