Section 12: BRAKE AND AIR SYSTEM

PA1553

29

30. FITTING TIGHTENING TORQUES

45

ο

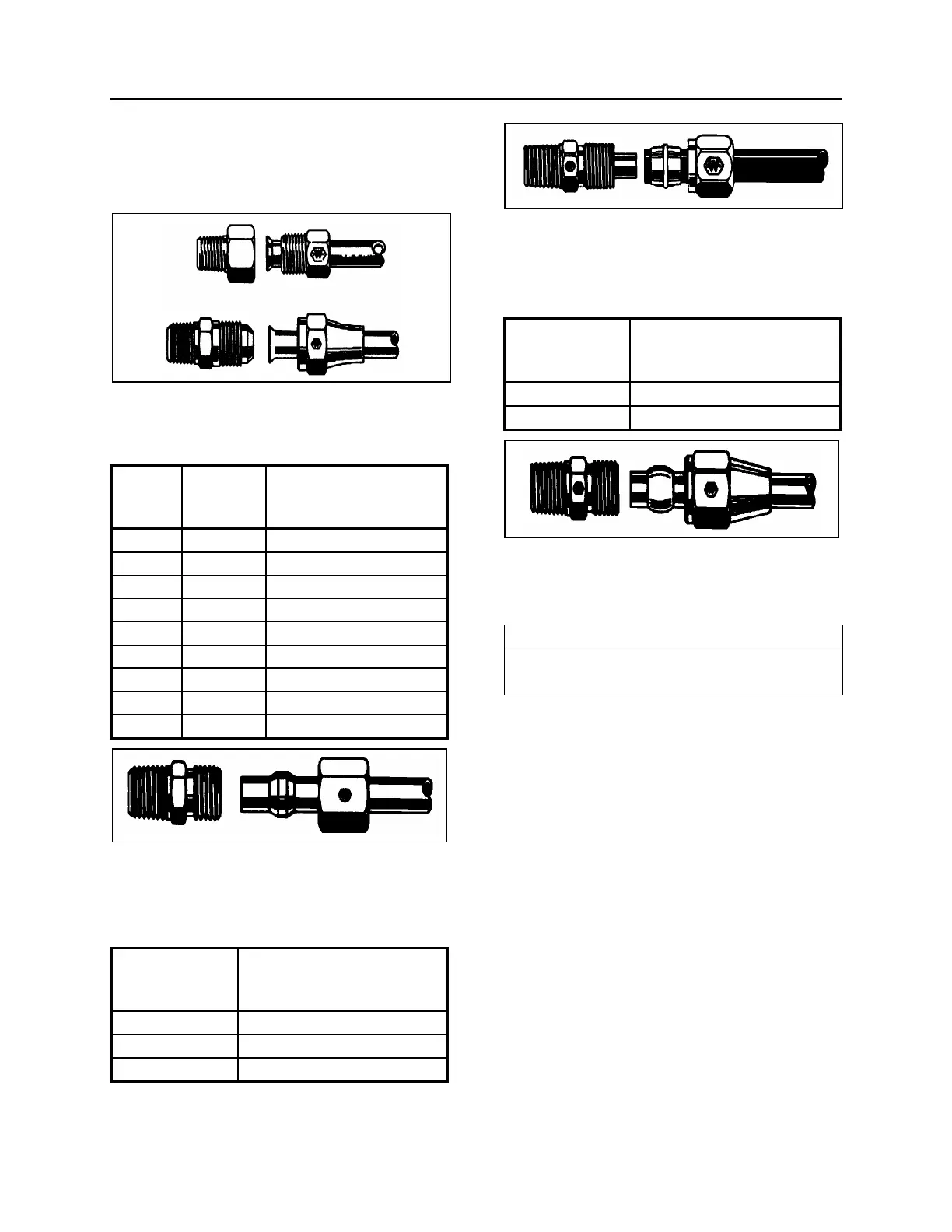

Flare and Inverted Flare: Tighten assembly

with a wrench until a solid feeling is encoun-

tered. From that point, tighten 1/6 turn (Fig. 47).

FIGURE 47: HOSE FITTINGS 12053

Compression: Tighten nut by hand (Fig. 48).

From that point, tighten using a wrench the

number of turns indicated in the chart hereafter.

Fitting

size

Pipe

diameter

(inches)

Number of additional

turns required following

hand tightening

2 1/8 1 ¼

3 3/16 1 ¼

4 1/4 1 ¼

5 5/16 1 ¾

6 3/8 2 ¼

8 1/2 2 ¼

10 5/8 2 ¼

12 3/4 2 ¼

16 1 2 ¼

FIGURE 48: HOSE FITTING 12054

NTA-Type Plastic Tubing: Hand tighten nut

(Fig. 49). From that point, tighten using a wrench

the number of turns indicated in the following

chart.

Tubing diameter

(inches)

Number of additional turns

required following hand

tightening

1/4 3

3/8 to 1/2 4

5/8 to 3/4 3 ½

FIGURE 49: HOSE FITTING 12055

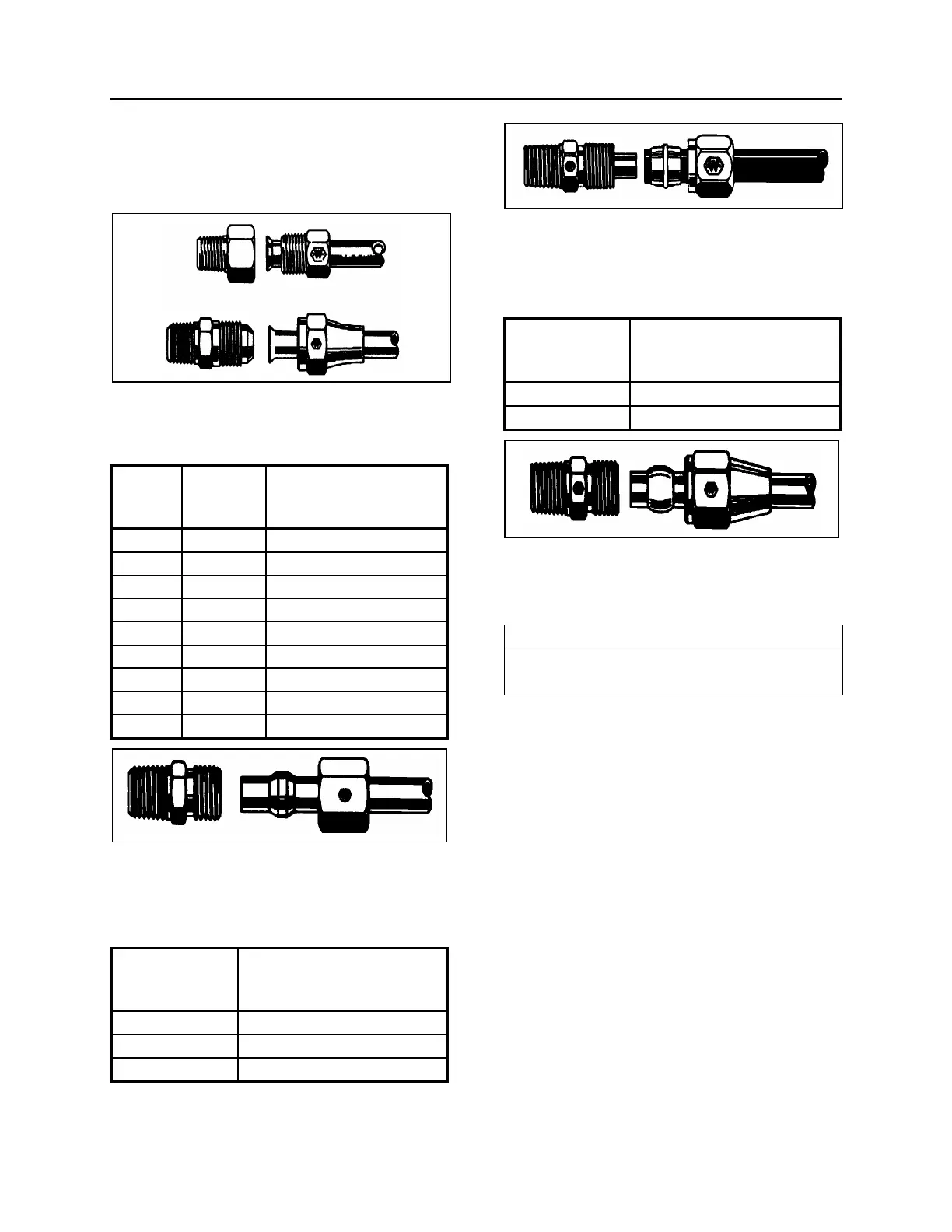

AB-Type Copper Piping: Hand tighten nut

(Fig. 50). From that point, tighten with a wrench

the number of turns indicated in the following

chart.

Piping diameter

(inches)

Number of additional turns

required following hand

tightening

1/4, 3/8, 1/2 2

5/8, 3/4 3

FIGURE 50: HOSE FITTING 12056

Pipe Tightening: All connections must be hand

tightened. From that point, tighten a minimum of

2 ½ additional turns.

NOTE

Use Locktite (Prévost number 680098) pipe

sealant to seal pipe thread.

Loading...

Loading...