Die Grinder. Used with a sanding wheel, cutting stone or grinding tool, this is

a version of an electric grinder. This tool is very quick and effective as well, and

care must be taken to remove metal as uniformly as possible and not to gouge

the wheel (photo 7 on page 15).

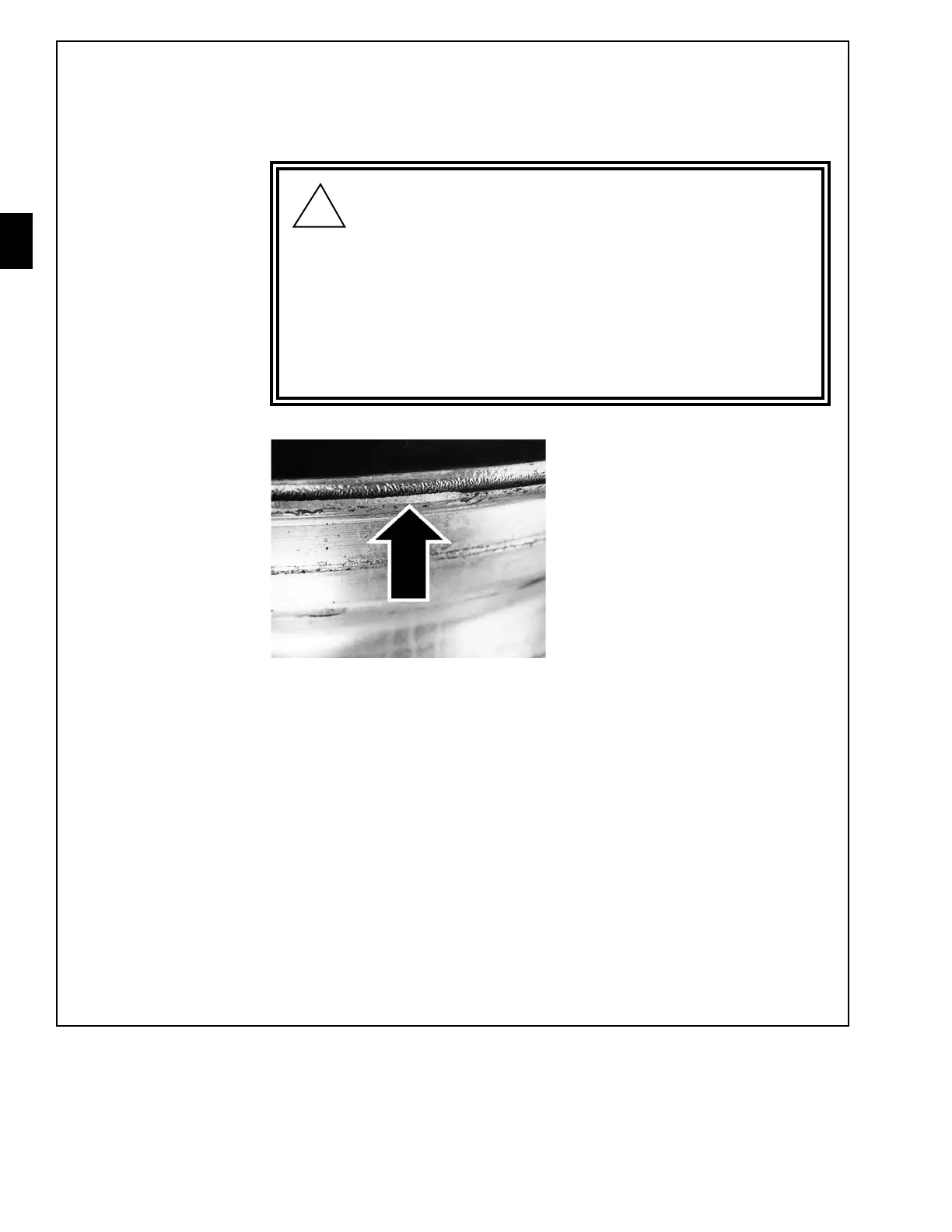

STEP 4. The photographs show the process of removing the edge. With whatever

tool is selected, work the tool around the wheel’s circumference removing only

enough material to eliminate the sharp edge. This should only be a small amount

of metal. Perform this work on both flanges if the there is evidence of sharpness.

Regardless of the method which you choose, the objective is to remove the sharp

edge (photo 8). Remove just enough metal to smooth the edge. Take care

to make sure the edge removal is as uniform as possible. Avoid gouging the wheel.

16

2

Rim flange

wear

(continued)

.

CAUTION

Removing sharp edges with hand or power tools produces

metal filings and sparks. Many power tools have edges that are

sharp or may become hot during use. Some power tools produce

excessive noise when used.

Metal filings can be sharp and, when projected by the action

of power tools, can cause serious skin or eye damage. Excessive

noise from power tools can harm hearing. Sharp edges can

produce cuts and hot surfaces can cause burns. Cuts and burns

can lead to infection.

Always wear appropriate safety gear such as protective eye wear,

gloves, protective clothing and hearing protection when using

hand or power tools.

CAUTION

!

Photo 8. Adequate repair for sharp edge

resulting from rim flange wear removes

just enough metal to smooth the edge.

Loading...

Loading...