4

33

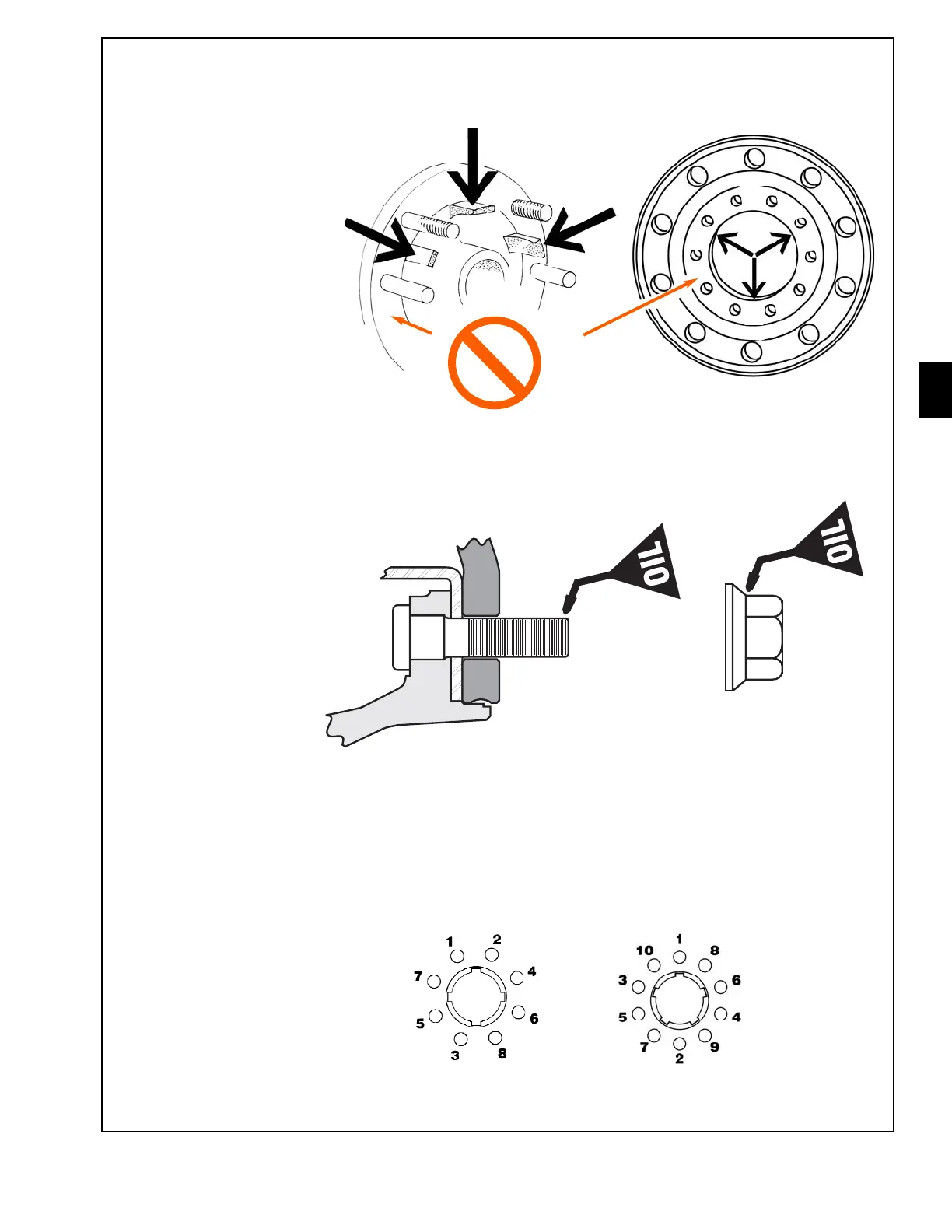

Tightening

hub piloted

mounting,

two-piece

flange nuts

(continued)

Lubricate the hub pads or the wheel hub bore generously with a non-water-based

lubricant.

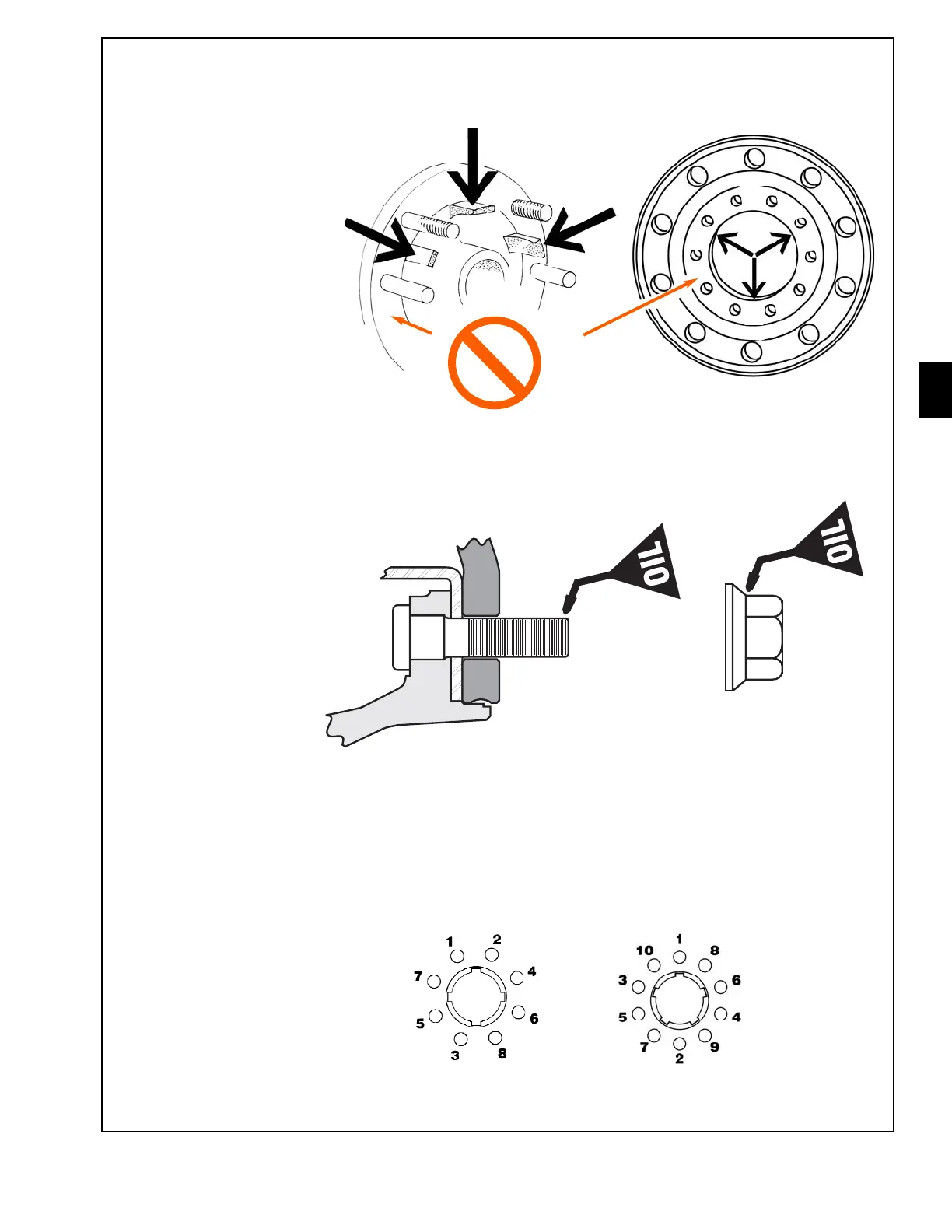

Eight Stud Ten Stud

Before installing two-piece flange nuts, lightly lubricate the stud threads and the contact

surfaces between the cap nut and the washer as illustrated below with an SAE 30W oil.

This will minimize corrosion between the mating surfaces. Lubrication is not necessary

with new hardware.

Position one of the hub’s pilot pads at the twelve o’clock position. After positioning

wheels on the pilot pads, hand tighten all two-piece flange nuts, then tighten to the

recommended torque following the proper sequence shown below for your type wheel.

After 50-100 miles of operation, torque should be rechecked. Check torque frequently

from then on. If nuts require frequent tightening, studs break frequently, or wheel bolt

holes are pounding out, hardware and mounting practices should be reviewed.

Do NOT lubricate

the face of the hub, wheel face

or brake drum

Lube

here

Lube

here

Lube

here

Lube

here

Lubricate here

Lubricate here

OIL

OIL

NOTICE: In service, stud

dimensions and condition

may change over time due

to environmental

conditions, multiple

re-installations, improper

torquing and other factors.

Consult with your hub

and stud manufacturer

for maintenance

and replacement

recommendations.

Loading...

Loading...