170 Rockwell Automation Publication 2198-UM002L-EN-P - October 2021

Chapter 5 Connect the Kinetix 5700 Drive System

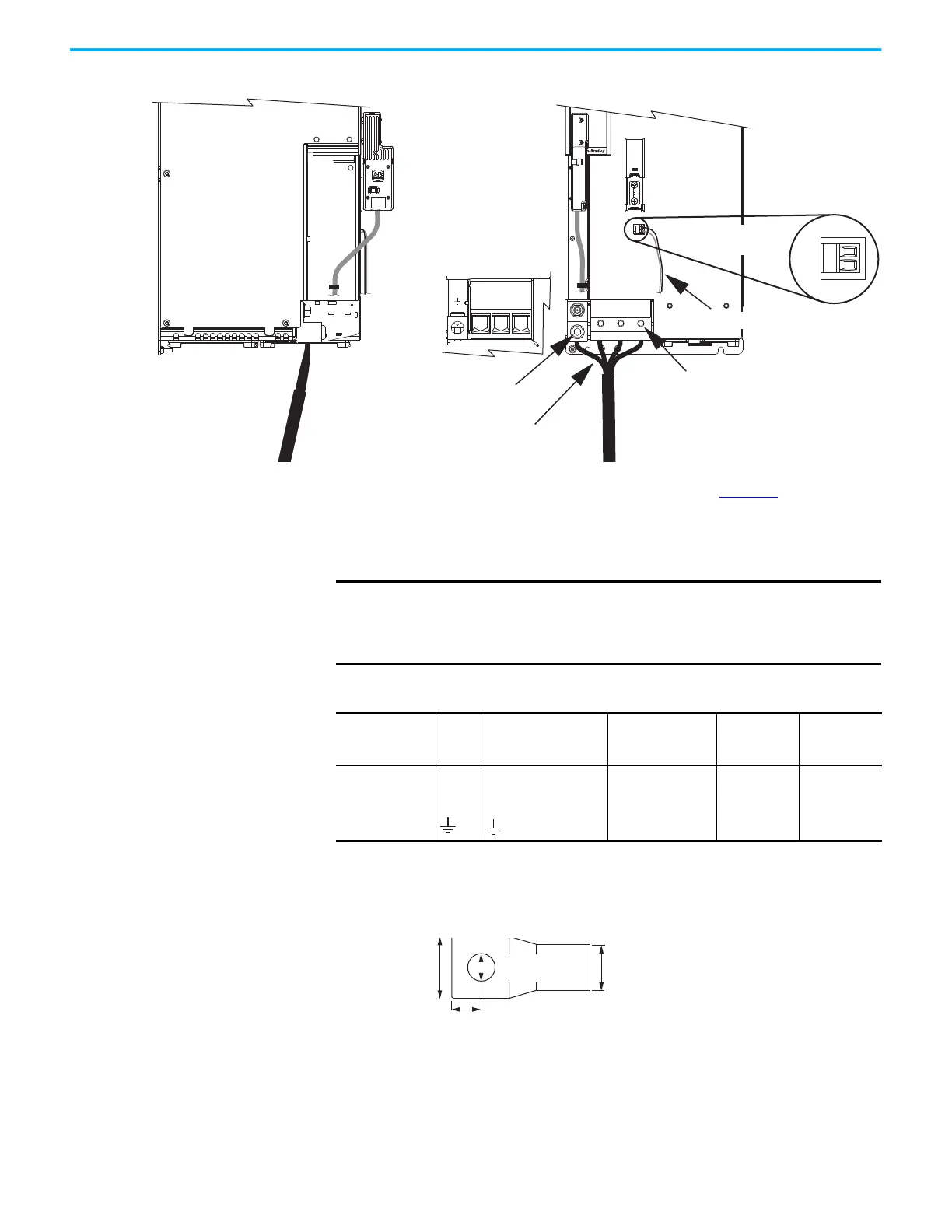

Figure 112 - MP and BC Connector Wiring (single-axis inverters)

Prepare the customer-supplied motor power cable (see page 169), then attach

motor power and ground wires to the motor power connector and ground

terminal. Plug in motor feedback and brake connectors, as required for your

application.

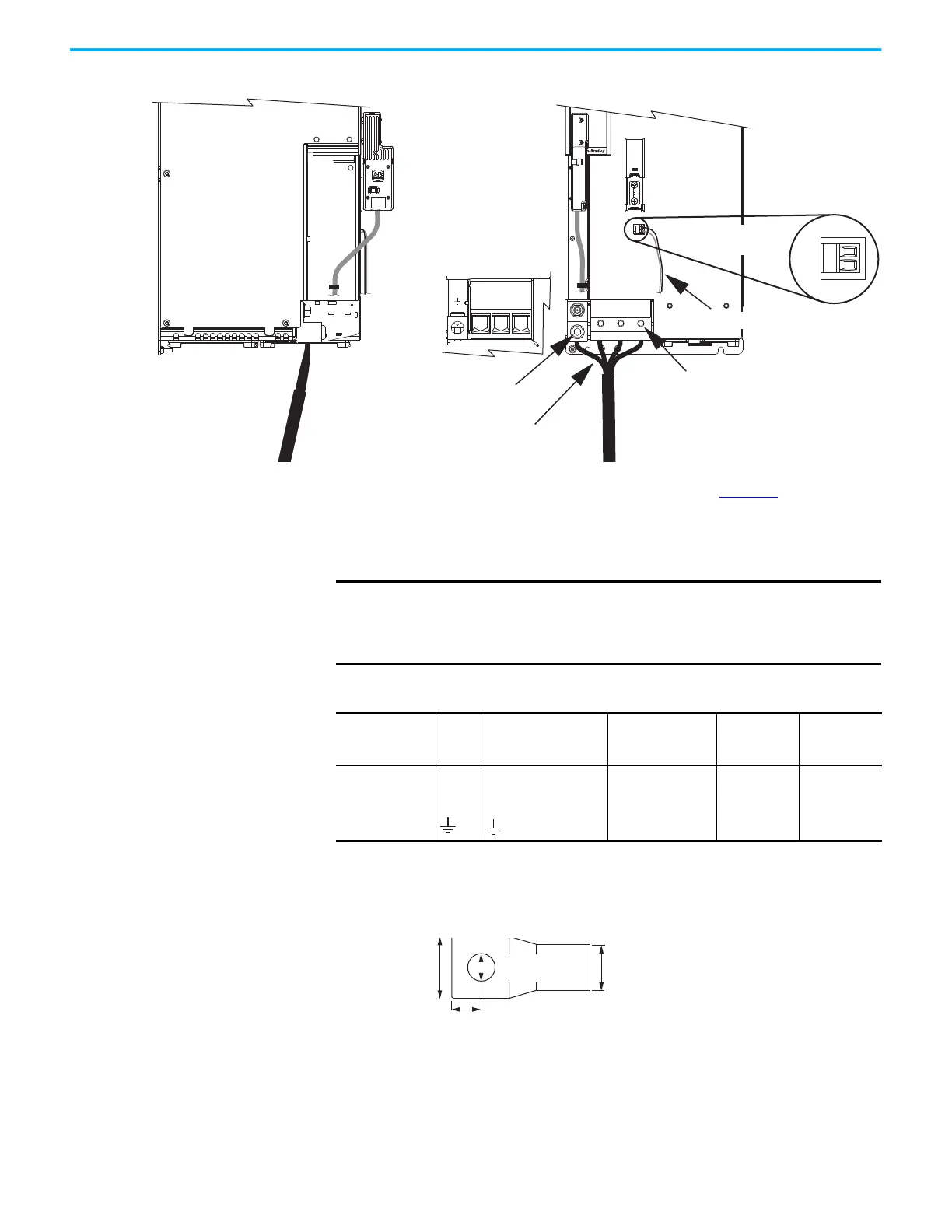

If you replace the ground-conductor termination block with a lug, the lug size

must not exceed these maximum dimensions.

Figure 113 - Maximum Customer-supplied Lug Dimensions

MBRK

+

-

21mm (4 AWG-250 kcmil)

15-20 Nm (132-177 lbin)

2

W V U

W V U

2

1

–

MBRK

+

Motor Cable

Connections

Motor Brake

(BC) Connector Plug

2198-S263-ERSx or

2198-S312-ERSx

Single-axis Inverters

(front view)

Motor Power

(MP) Connector

(bottom view)

Motor Power (MP) Connector

Screws (3x): 6 mm Hex Driver

Torque: 15…20 N•m (132…177 lb•in)

Motor Power Ground Terminal

Screw: 8 mm Hex Driver

Torque: 5.6 N•m (50 lb•in)

2198-S263-ERSx or

2198-S312-ERSx

Single-axis Inverters

(side view)

Customer-supplied Motor Power Cable

2198-K57CK-D15M

Motor Feedback

Connector Kit

Customer-supplied Motor Brake Cable

IMPORTANT

The supplied ground terminal is suitable for use with 16…120 mm

2

(6 AWG…250 kcmil) Class B and C power cables and all Allen-Bradley

Kinetix 2090 motor cables. A customer-supplied lug is required for all

other applications.

Table 101 - Motor Power Connector Specifications (single-axis inverters)

Drive Module

Cat. No.

Pin Signal/Wire Color

Recommended Wire

Size

mm

2

(AWG)

Strip Length

mm (in.)

Terminal

Torque Value

N•m (lb•in)

2198-S263-ERSx

2198-S312-ERSx

21.1…120

(4…250 kcmil)

27.0 (1.06)

15…20

(132…177)

Brown

Black

Blue

Green/Yellow

U

V

W

25.4 mm

(1.00 in.)

11.43 mm

(0.45 in.)

Lug size according to cable size and

classification. Flexible wires (Class K…G)

must use flex-rated lugs.

8 mm (0.315 in.)

(inside diameter hole)

Loading...

Loading...