Rockwell Automation Publication 2198-UM002L-EN-P - October 2021 159

Chapter 5 Connect the Kinetix 5700 Drive System

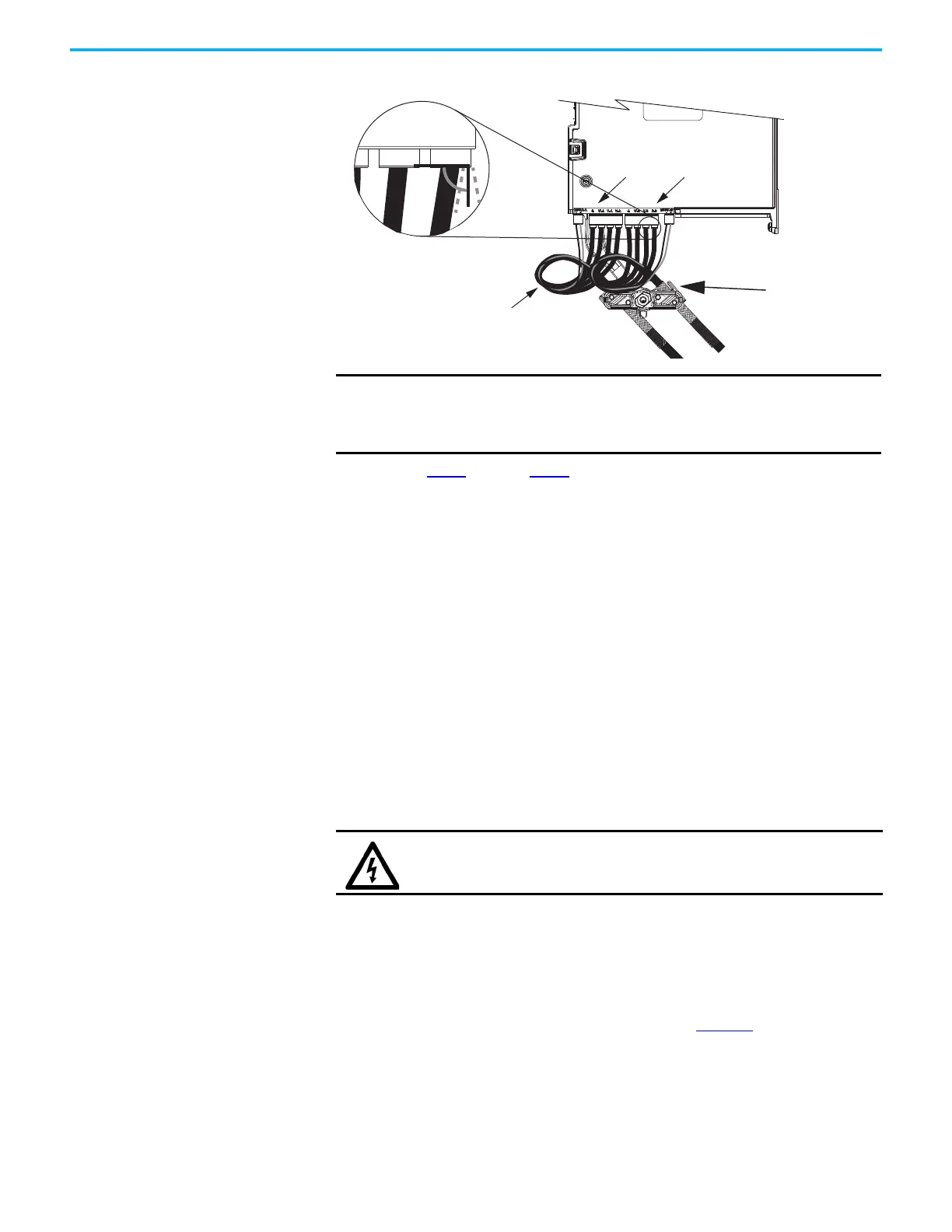

Figure 103 - Dual-axis Inverter Cable Installation (series A and B, 12 and 10 AWG cable)

4. Repeat step 1 through step 3 for each dual-axis inverter.

Single-axis Inverter Power/Brake Cable Installation

All single-axis inverters include a cable-shield clamp bracket that is designed to

ground (bond) 2090-CPBM7DF cable shields with the drive chassis.

• 2198-S086-ERSx, 2198-S130-ERSx, and 2198-S160-ERSx single-axis

inverters include a two-position cable-shield clamp that accommodates

10, 8, 6, 4, and 2 AWG power conductors. The clamp bracket is connected

to the motor power connector and ships with the drive.

•2198-S263-ERSx and 2198-S312-ERSx single-axis inverters include a

single-position cable-shield clamp that accommodates 4 and 2 AWG

power conductors. The clamp bracket ships with the drive, but requires

some assembly.

2090-CPBM7DF (series B) 10 AWG cables are designed for use with

Kinetix 5700 single-axis inverters and do not require any modifications.

For single-axis inverters, the 2090-CPBM7DF (series A) cable power

conductors, 102 mm (4.0 in.), require adjustment only when the smaller (upper

position) clamp is used. The upper position is for smaller cables (10, 8, and 6

AWG). The lower position is for larger cables (4 and 2 AWG). We recommend

that you measure from the edge of the cable jacket (that is covered with heat

shrink) and trim the power conductors as shown in Table 94

.

Clamps Compressed

Around Shields Close

to the Heat Shrink

Dual-axis Inverter

(side view)

Motor Power (MP) and

Motor Brake (BC) Connectors

Kinetix 2090-CPBM7DF

Power/Brake Cables

Service loops provide stress relief and the

conductors enter into the motor and brake

connectors at approximately 90°

(between 75 and 105° is acceptable).

75°…105°

Entry Into

Connectors

IMPORTANT

Avoid sharp bends in the power and brake conductors. You must

route the power and brake conductors from where they exit the

clamp and enter the motor and brake connectors so that stress-relief

bends or service loops are formed.

SHOCK HAZARD: To avoid hazard of electrical shock, make sure shielded

power cables are grounded according to recommendations.

Loading...

Loading...