Rockwell Automation Publication 2198-UM002L-EN-P - October 2021 47

Chapter 2 Plan the Kinetix 5700 Drive System Installation

Refer to the Kinetix 5700, 5500, 5300, and 5100 Servo Drives Specifications

Technical Data, publication KNX-TD003

, for additional power specifications

for your 2198-Pxxx DC-bus power supply and 2198-RPxxx regenerative bus

supply.

24V Control Power Evaluation

The Kinetix 5700 drive system requires 24V DC input for its control circuitry.

Due to the 24V shared-bus connection system and the 24V current

requirements of the Kinetix 5700 drives, a thorough evaluation of control

power is required prior to implementation. Consider the following when

sizing such a system:

• Verify that the 24V DC power supply is capable of supplying the 24V

current requirements of your Kinetix 5700 drive system. See Calculate

24V DC Control Power Current Demand on page 378 to determine the

24V current requirements. For systems with a high 24V current demand,

consider the following:

- Install separate 24V power supplies for each cluster or change the

cluster configuration to more evenly divide the 24V current demand.

- Install separate 24V power supplies for each Bulletin 2198 power

supply and inverter.

• Verify that the wiring being used is capable of supplying the Kinetix 5700

drive system with a voltage within the 24V input-voltage range; 24V ±10%

(21.6…26.4V DC). Consider the following:

- Mount the 24V power supply as close to the Kinetix 5700 drive system

as possible to minimize input voltage drop.

- Install larger gauge wire, up to 4 mm

2

(12 AWG) and 6 mm

2

(10 AWG)

for 24V control power when using the CP connectors included with the

module; or use the 24V shared-bus connection system to lower the DC

wire resistance with up to 10 mm

2

(6 AWG) and result in a lower

voltage drop.

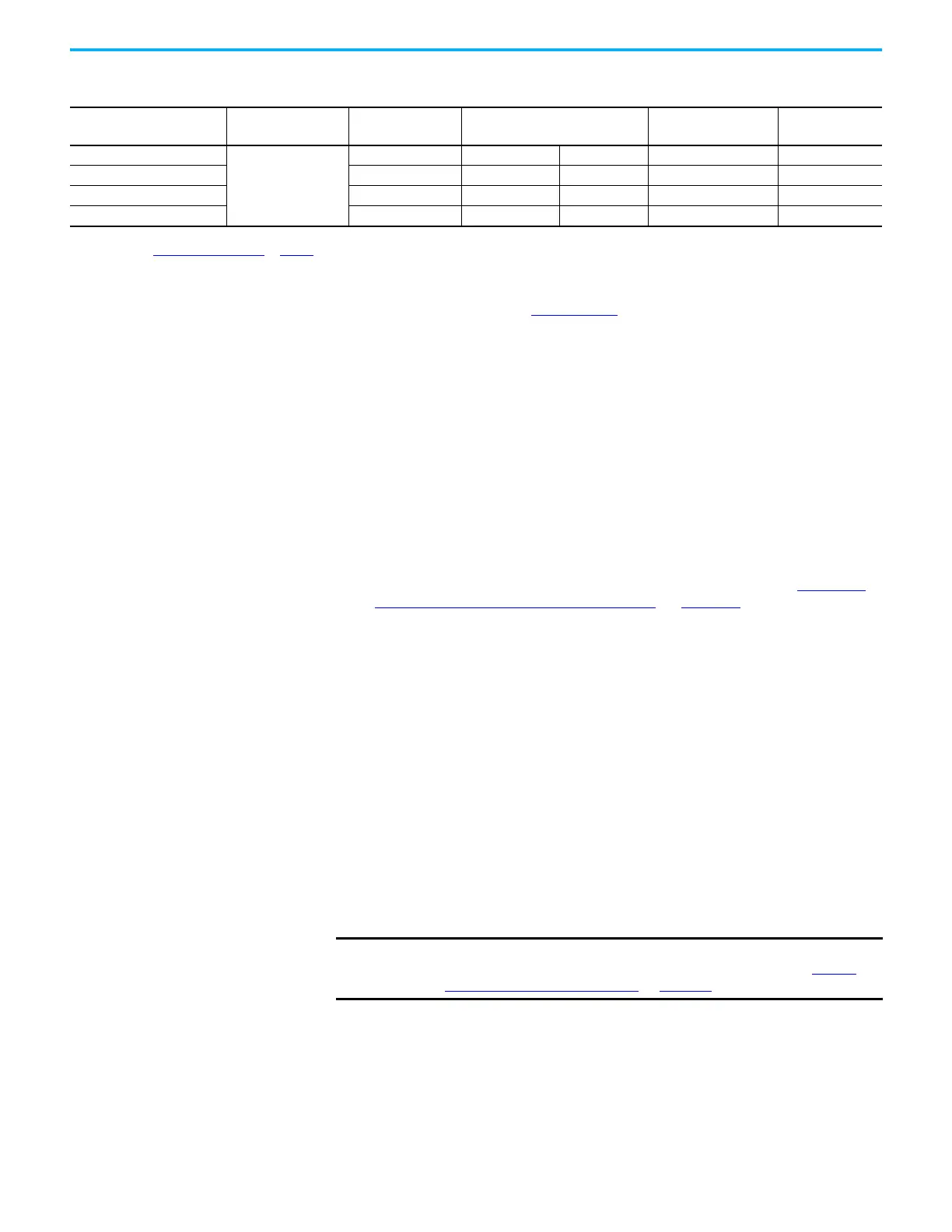

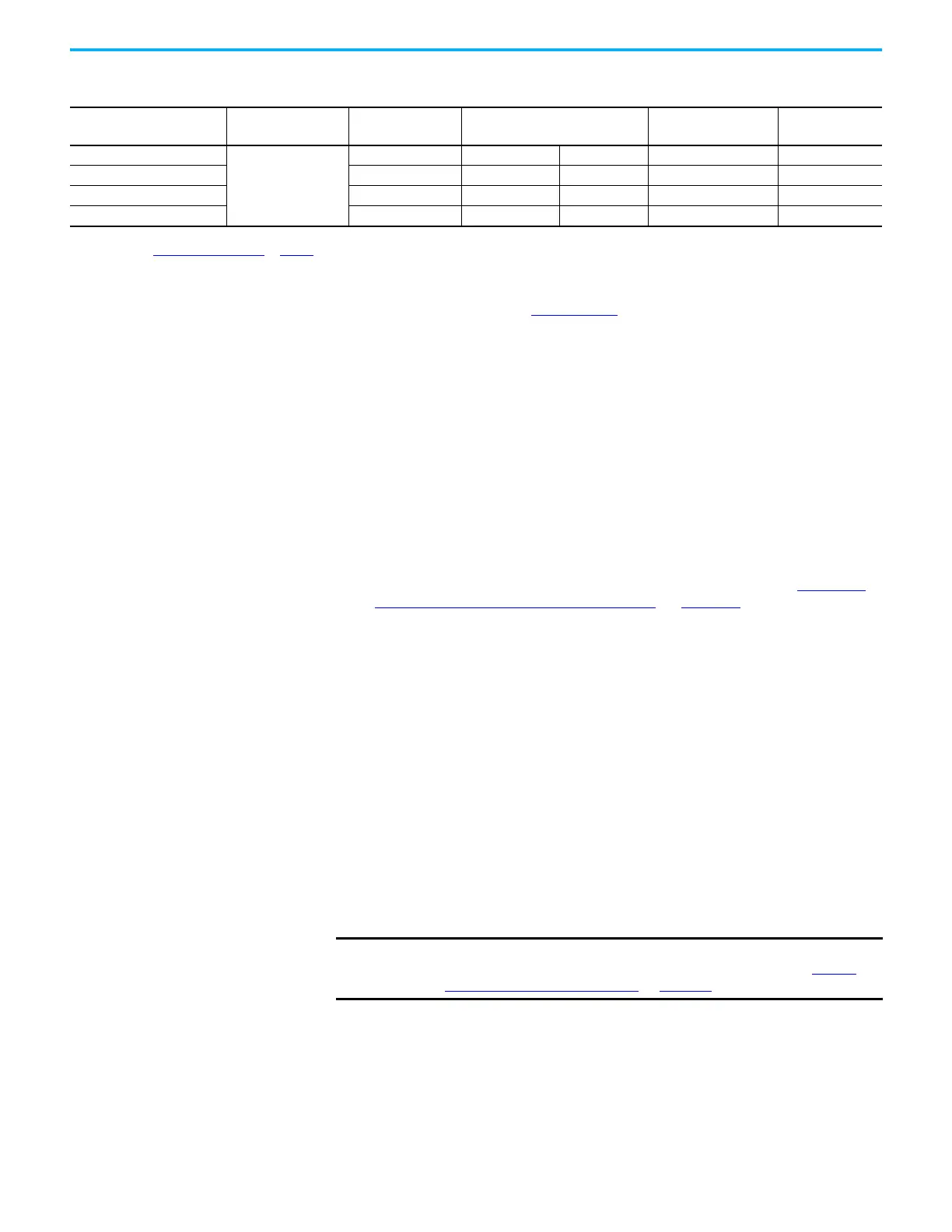

Table 12 - Regenerative Bus Supply IEC (non-UL/CSA) Circuit-protection Specifications

Regenerative Bus Supply

Cat. No.

Input Voltage

(1)

(three-phase) nom

DIN gG Fuses

Amps, max

Miniature CB

Cat. No.

Motor Protection CB

Cat. No.

Molded Case CB

Cat. No.

2198-RP088

324…506V AC rms

50 1489-M3C600 1492-SPM3C630 140MG-H8E-C60 140G-G6C3-C60

2198-RP200 125 – – 140MG-J8E-D15 140G-J6F3-D15

2198-RP263 200 – – – 140G-K6F3-D30

2198-RP312 250 – – – 140G-K6F3-D40

(1) Applies when DC-bus voltage regulation is enabled. If DC-bus voltage regulation is not enabled, then the input voltage range is 324….528V AC. For more information on these two modes of

operation, see DC-bus Voltage Regulation

on page 40.

IMPORTANT

The 24V current demand, wire gauge, and wire length all impact the

voltage drop across the wiring being used. For an example, see 24V DC

Voltage Drop Calculation Example on page 379.

Loading...

Loading...