Rockwell Automation Publication 2198-UM002L-EN-P - October 2021 303

Chapter 9 Kinetix 5700 Safe Torque-off Function

Safety Application Requirements

Safety application requirements include evaluating probability of failure rates

(PFH), system reaction time settings, and functional verification tests that

fulfill SIL 3 criteria. Refer to Average Frequency of a Dangerous Failure

on

page 285

for more PFH information.

Creating, recording, and verifying the safety signature is also a required part

of the safety application development process. Safety signatures are created by

the safety controller. The safety signature consists of an identification

number, date, and time that uniquely identifies the safety portion of a project.

This includes all safety logic, data, and safety I/O configuration.

For safety system requirements, including information on the safety network

number (SNN), verifying the safety signature, and functional verification tests

refer to the appropriate GuardLogix controller publication as defined in

Additional Resources

on page 13.

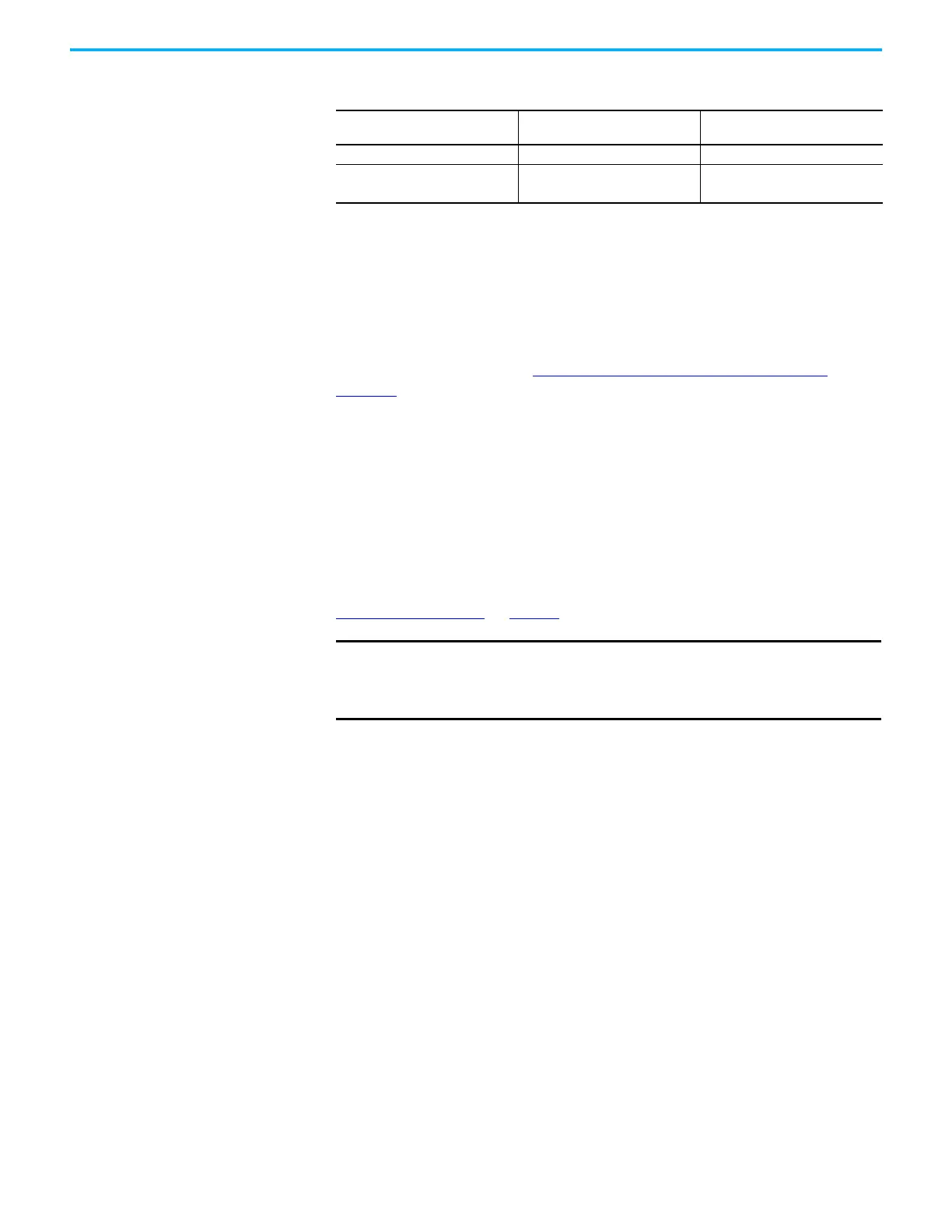

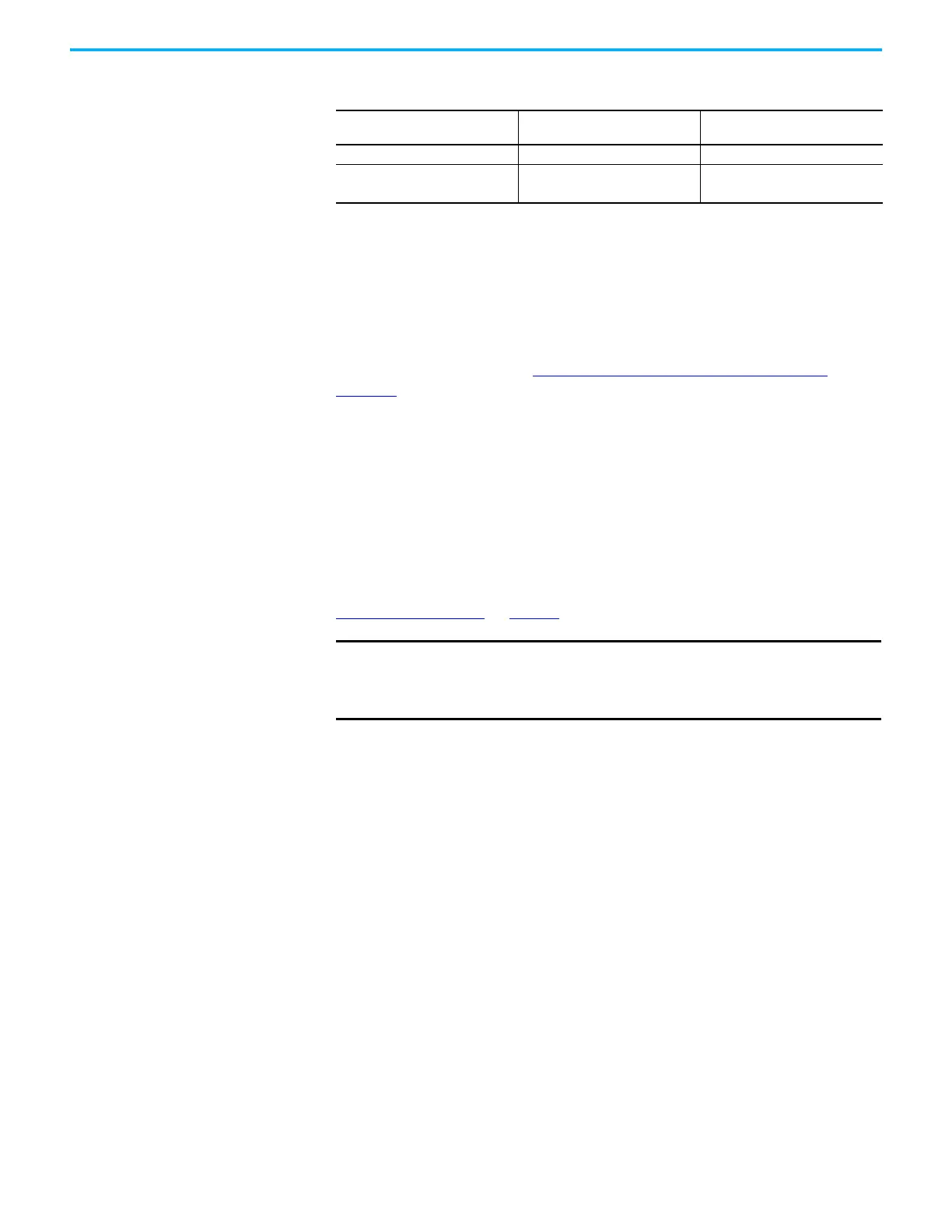

Table 168 - Studio 5000 Logix Designer Requirements

Studio 5000 Logix Designer

Application

Kinetix Dual-axis Inverters

Cat. No.

Kinetix Single-axis Inverters

Cat. No.

Version 26 or later 2198-Dxxx-ERS3 (series A) 2198-Sxxx-ERS3 (series A)

Version 31 or later

2198-Dxxx-ERS4

2198-Dxxx-ERS3 (series B)

(1)

(1) When 2198-xxxx-ERS3 (series B) drives are used in Timed SS1 safety applications, Studio 5000 Logix Designer application,

version 31, must be used.

2198-Sxxx-ERS4

2198-Sxxx-ERS3 (series B)

IMPORTANT

You must read, understand, and fulfill the requirements detailed in

the GuardLogix controller systems safety reference manual prior to

operating a safety system that uses a GuardLogix controller and

Kinetix 5700 drive.

Loading...

Loading...