Rockwell Automation Publication 2198-UM002L-EN-P - October 2021 399

Appendix F Motor Control Feature Support

Basic Volts/Hertz

Volts/hertz operation creates a fixed relationship between output voltage and

output frequency. Voltage is applied to the motor, which is based on the

operating frequency command at a fixed volts/hertz ratio. The ratio is

calculated from the motor nameplate data and entered into the Logix Designer

application>Axis Properties>Frequency Control category.

The Basic Volts/Hertz method provides various patterns. The default

configuration is a straight line from zero to rated voltage and frequency. As

seen in Figure 209

, you can change the volts/hertz ratio to provide increased

torque performance when required by programming five distinct points on

the curve.

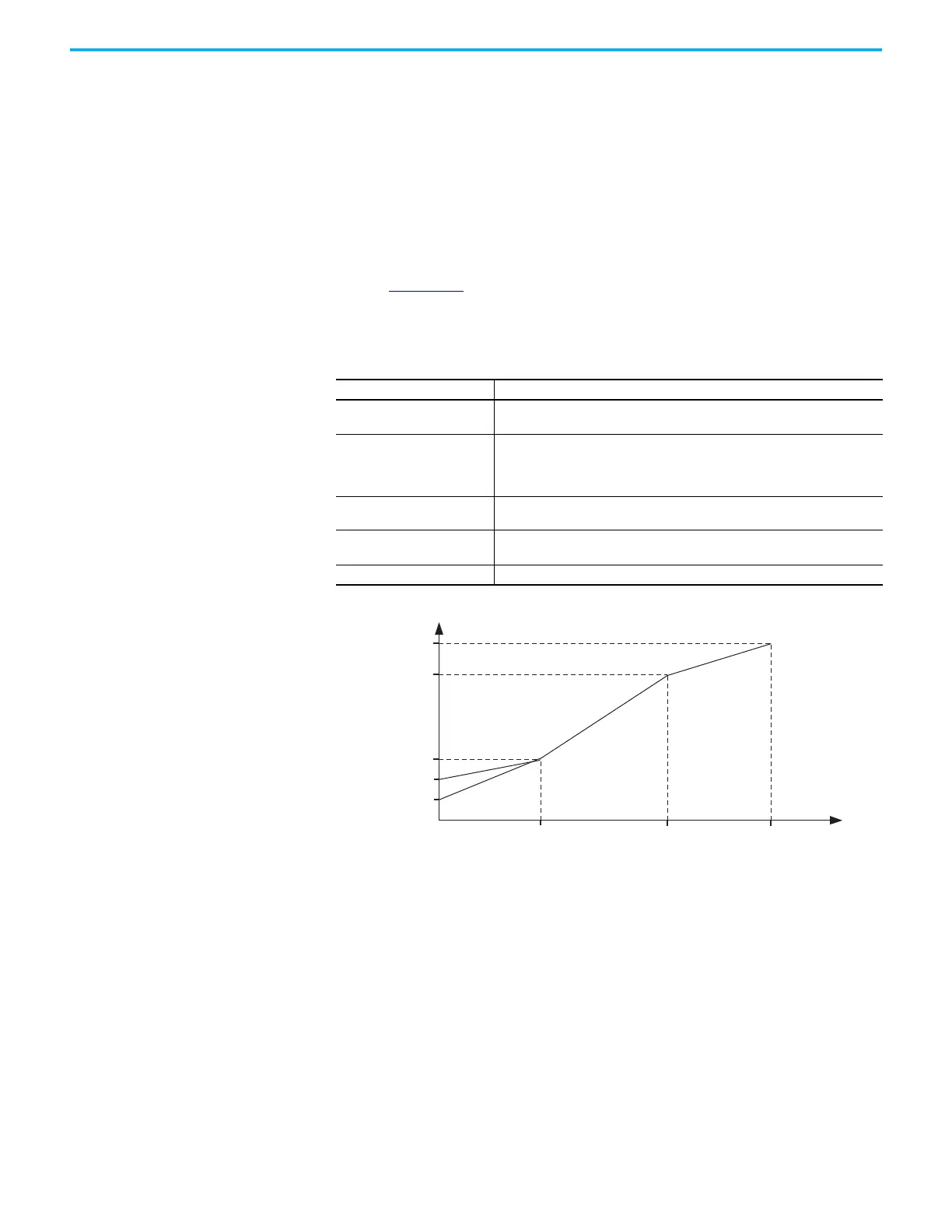

Figure 209 - Basic Volts/Hertz Method

Table 198 - Basic Volts/Hertz Definitions

Curve Feature Definition

Start boost

Used to create additional torque for breakaway from zero speed and

acceleration of heavy loads at lower speeds.

Run boost

Used to create additional running torque at low speeds. The value is typically

less than the required acceleration torque. The drive lowers the boost voltage to

this level when running at low speeds (not accelerating). This reduces excess

motor heating that could result if the higher start/accel boost level were used.

Break voltage/frequency

Used to increase the slope of the lower portion of the Volts/Hertz curve,

providing additional torque.

Motor nameplate voltage/

frequency

Sets the upper portion of the curve to match the motor design. Marks the

beginning of the constant power region.

Maximum voltage/frequency Slopes the portion of the curve that is used above base speed.

Frequency,

max

Base Frequency,

(nameplate)

Break Voltage

Start/Accel Boost

Run Boost

Base Voltage

(nameplate)

Voltage, max

Break

Frequency

Loading...

Loading...