5-10 Rapidlab 1200 Operator’s Guide: Maintenance

02087462 Rev. V

Performing Quarterly Maintenance

The quarterly maintenance schedule is based on analyzing 30 samples per day, unless

otherwise noted. If your laboratory analyzes more than 30 samples per day, perform this

maintenance more frequently.

Replacing the Pinch Valve Tubing

You need a tubing kit for this task.

BIOHAZARD: Wear personal protective equipment. Use universal precautions.

Refer to Appendix A, Protecting Yourself from Biohazards for

recommended

precautions when working with biohazardous materials.

1. At the user interface, select Status > Diagnostics > Cartridges.

2. Select

Eject R Cartridge.

3. Lift the door on the measurement module.

Refer to Preparing for Maintenance Procedures‚ page 5-1.

4. Remove the old tubing:

a. Remove the tubing from the connector at the spring-loaded latch.

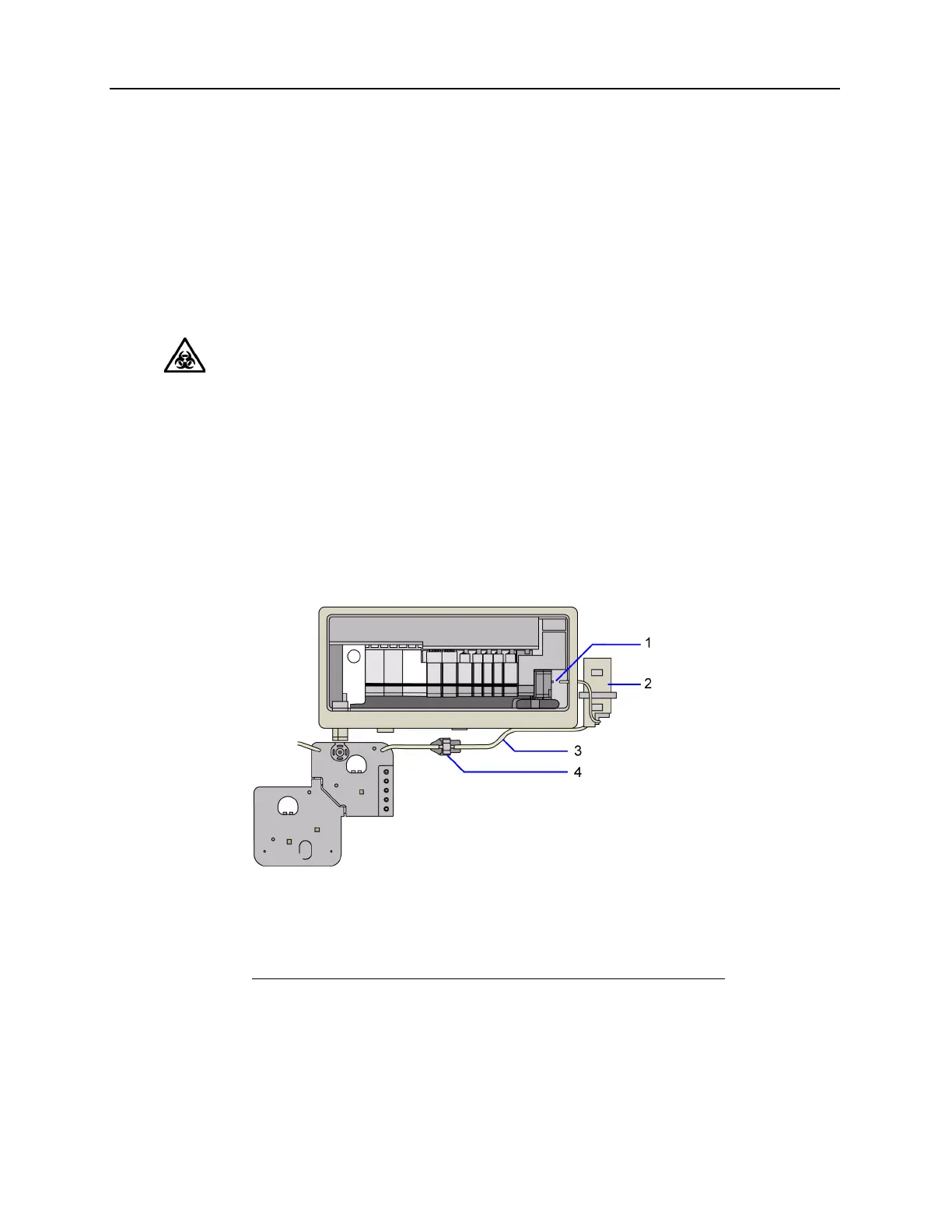

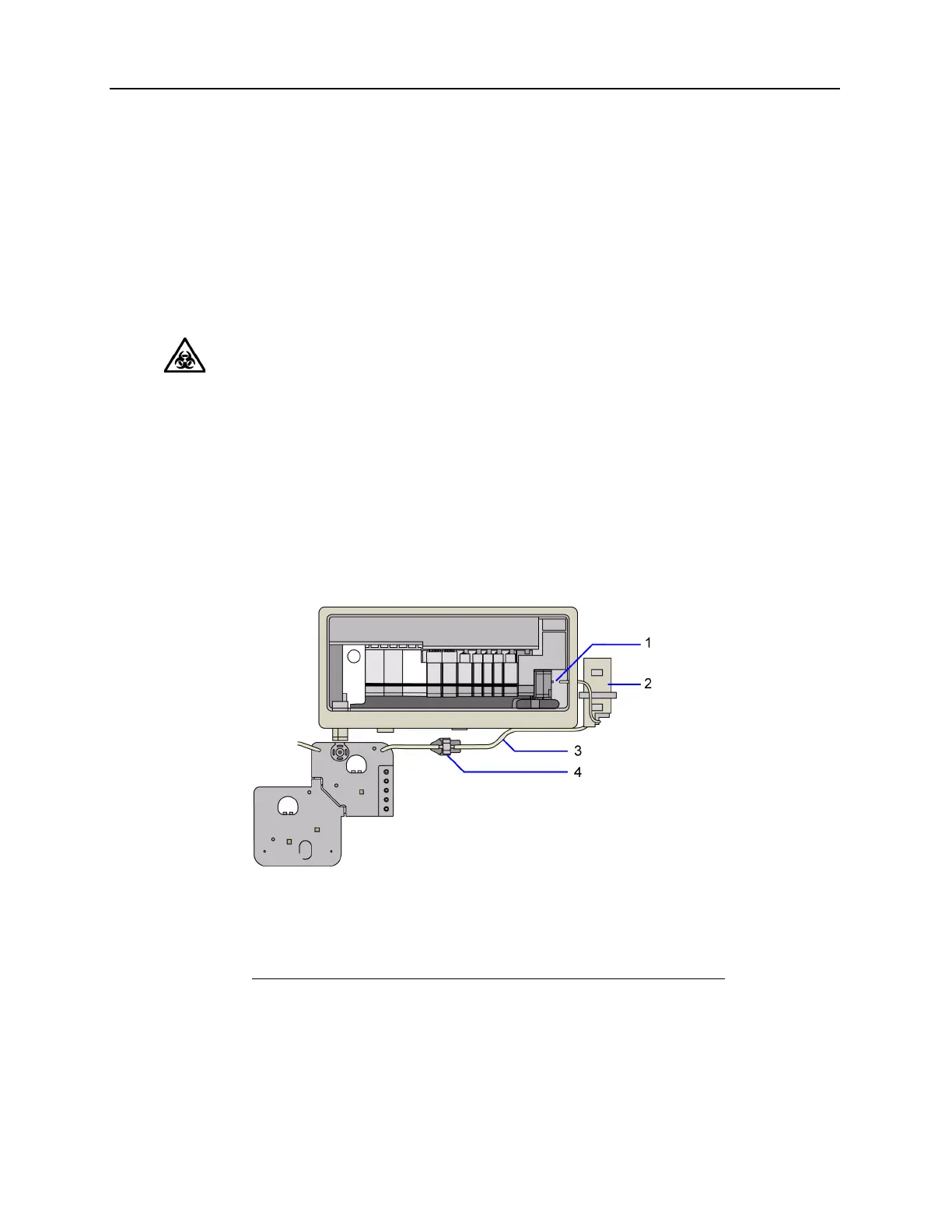

Figure 5-2 Measurement Module–Rapidlab 1260 and 1265 Systems

b. Pull the tubing out of the pinch valve.

1 Connector at the spring-loaded latch

2 Pinch valve

3 Pinch valve tubing

4 Pressure sensor bubbler

Loading...

Loading...