01/02

1-13

8825/8830 Printer

Maintenance Procedures

Service Call Procedures

NOTE: 1. Ensure that the vacuum does not contact the edge of the cleaner blade that touches

the surface of the photoreceptor drum.

NOTE: 2. Where possible, dust the drum and the cleaning blade with zinc stearate away from

the xerographic module to prevent the charge scorotron from being contaminated. If the drum

and cleaning blade must be dusted while in the xerographic module, remove the charge

scorotron. The zinc stearate will contaminate the charge scorotron and cause print quality

defects.

NOTE: 3. Install the complete cleaning blade kit when installing a new photoreceptor.

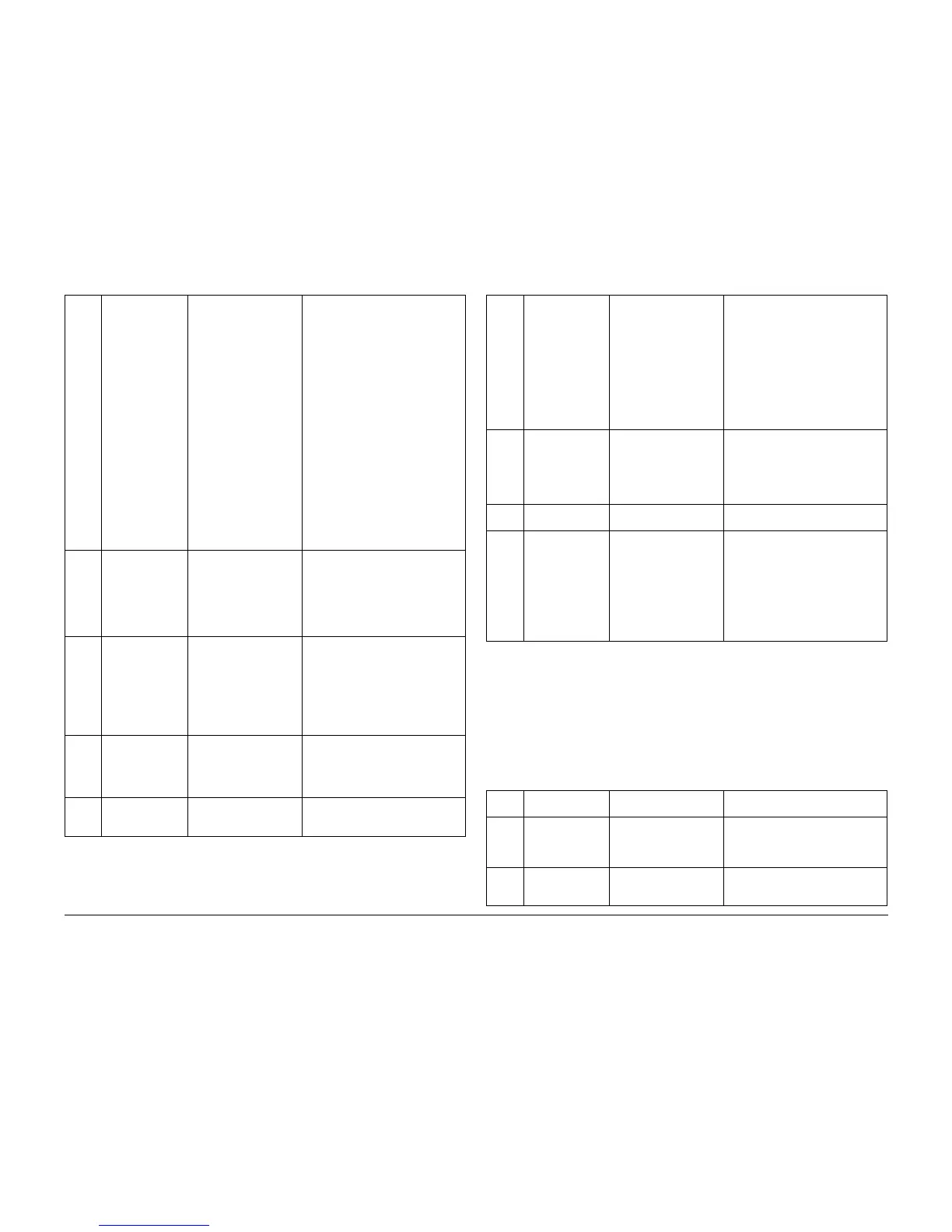

Nor-

mal

Call

Clean the xero-

graphic module.

Clean the erase

lamp.

Inspect the photo-

receptor for dam-

age.

Inspect compo-

nents for vellum

contamination.

Inspect all seals

for damage.

Inspect the

Cleaner Blade for

damage.

Contamination can cause

print quality problems.

Contaminants can travel

to the LED bar and

scorotrons, which results

in print quality problems.

Fused toner on the bot-

tom of the module can

cause jams.

Contamination reduces

the effectiveness of the

lamp to discharge the

photoreceptor drum.

Contaminants from vel-

lum

- Cleaner failure

- Contaminants to prints.

Vellum contamination will

contaminate and plug the

cleaner auger at the

ends.

Clean the toner from the housing and

cleaner blade with a vacuum cleaner.

NOTE: Ensure that the vacuum

cleaner does not contact the edge of

the cleaner blade that touches the

surface of the photoreceptor drum.

Perform the Photoreceptor Cleaning

Enhancement procedure in section 6.

Use cleaning solvent to remove any

fused toner from the bottom of the

module. Replace the photoreceptor if

damaged.

Clean the erase lamp with a brush or

dry lint free cloth.

Replace any damaged xerographic

module seals.

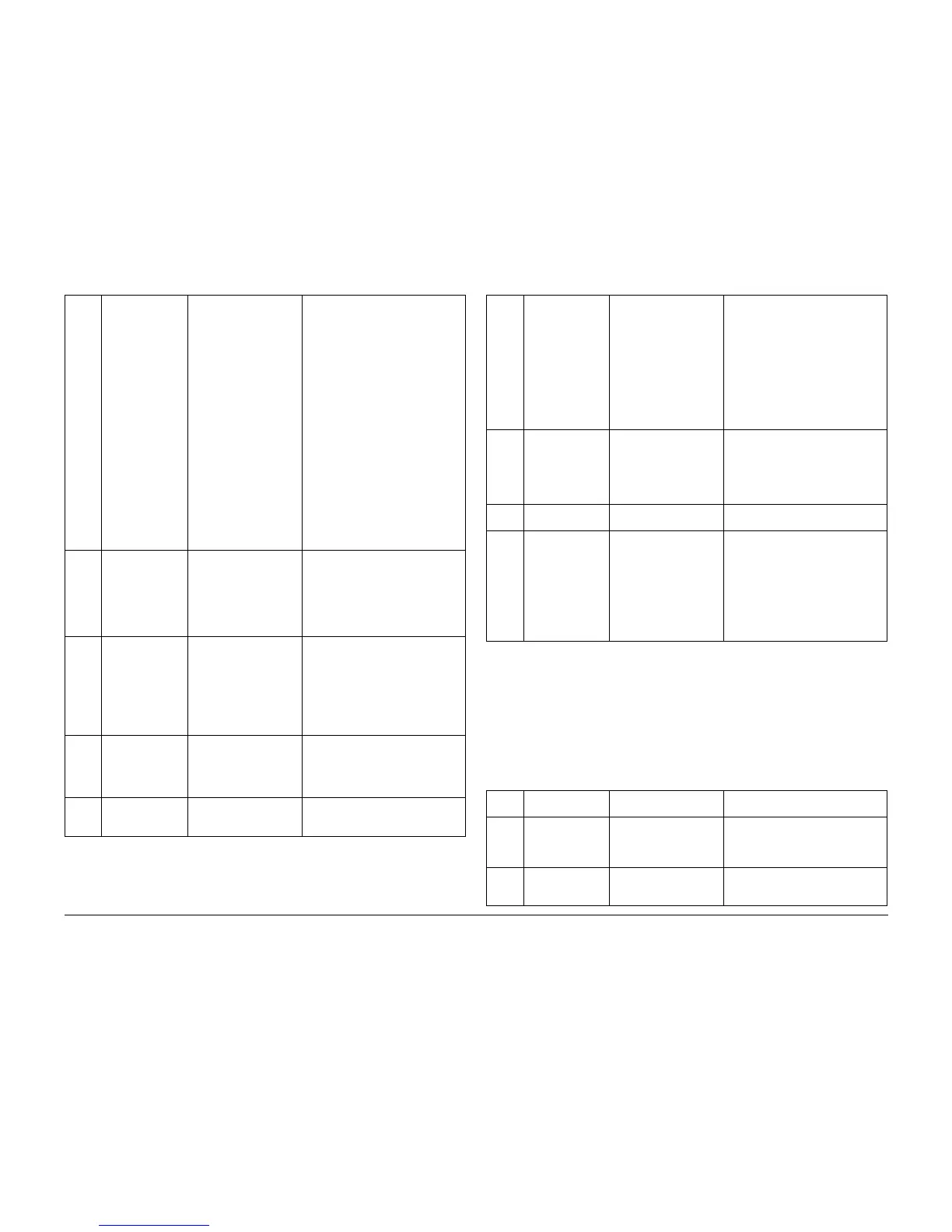

Nor-

mal

Call

Check and clean

or replace the

Stripper Fingers.

Clean the Media

Guides.

Bent stripper fingers may

cause feed out jams and

heat roll damage.

Contaminated or dam-

aged media guides can

cause print quality

defects.

Replace the damaged or contami-

nated stripper fingers.

Nor-

mal

Call

Clean/check the

Fuser Roll fabric

guide. Replace the

Fuser Roll.

Smooth or worn fuser roll

loses ability to drive

media.

Contaminated fabric

guide causes too much

resistance to media

which results in jams/

deletions/wrinkles.

Clean the roll with film remover.

Clean the fabric guide with formula A

and film remover.

Perform diagnostic code 1033 every

time the oiler is removed.

Nor-

mal

Call

Check the fuser

roll for lack of oil.

Too little oil can cause

media handling and off-

setting print quality prob-

lems.

Check remaining fuser web life

[1034] and adjust the web oiler rate

[1032].

If the fuser roll is dry, refer to BSD

10.2.

Nor-

mal

Call

Inspect/clean the

thermistor pad

Contamination can cause

fuser heat problems.

Clean the thermistor pad with a brush

or dry lint free cloth.

Table 2 Xerographic Module

As

Requir

ed

Check/clean the

photoreceptor.

Contamination/wear,

scratches, or chips can

generate print quality

problems.

Inspect photoreceptor surface for

deep scratches, chips or excessive

wear. Replace photoreceptor if dam-

aged.

Apply zinc stearate to the cleaning

blade and photoreceptor drum. *Note

2

Clean photoreceptor surface with

Xerox Film Remover if contaminated.

Apply zinc stearate when surface is

dry.

As

Requir

ed

*Note 3

Check/clean the

cleaning blade.

Replace with the

new photorecep-

tor or as required.

Residual image, streaks,

drum scuffing can occur if

the blade is worn or con-

taminated.

Vacuum clean the cleaning blade.

*Note 1

Apply zinc stearate to the cleaning

blade and photoreceptor drum. *Note

2

Replace the blade if damaged.

30K ft.

9Km

Replace the fabric

guide.

Jams, deletions, wrinkles. Refer to REP 8.9

30K ft.

9Km

Clean the inner

xerographic mod-

ule components.

If the customer is running

a high percentage of vel-

lum, outgassing of the

vellum contaminates the

cleaner auger and lower

baffle surface resulting in

poor cleaning and high

dirt contamination.

plugged cleaner auger

Remove the fuser roll and photore-

ceptor to enable access.

NOTE: Use caution not to touch or

damage cleaning blade or seals.

Vacuum the Xero Mod and Auger

and then clean all contaminated

areas with Film Remover.

Table 3 Media Transport

INTER

VAL

TASK REASON TASK ENABLER

Nor-

mal

Call

Clean the lower

paper transports,

turnaround baffle,

paper feed rolls.

Contaminates can cause

the media to slip resulting

in print quality defects.

Clean the transport with antistatic

fluid and a lint free cloth.

Clean the feed roller with Formula A.

Nor-

mal

Call

Clean the under

side of the trans-

port.

Reduce the airborne con-

taminants.

Vacuum clean, then wipe down with a

lint free cloth.

Table 2 Xerographic Module

Loading...

Loading...