01/02

6-10

8825/8830 Printer

Special Tests

General Procedures

[1010] Fuser Scorch Sensor

(Thermistor RT2)

1 = Fuser temperature less than or equal to 420

° F

(215

°C)

0 = Fuser temperature greater than 420

° F (215°C)

NOTE: Power must be switched OFF then ON, in order

to reset signal.

[1026] Reset the Fuser Control NVM to default values.

[1030] Reset Oil Web.

Resets the web counter when a new web has been

installed.

[1031] Specify Oil Web Position.

Used if the NVM fails or is reset. This sets the controls

for web use. (Enter the diameter of the supply spool in

millimeters.)

[1032] Specify Web Oil Rate.

This is used to adjust the web oil rate from 50% to

200%. (A 100% setting is nominal.) This setting directly

impacts the life of the Oil Web. 50% means that 1/2 as

much web is used.

[1033] Advance Oil Web.

Used to tension the web correctly when the oil assembly

is removed and reinstalled.

[1034] Estimate Oiler Web Life.

Displays the remaining web life in print feet or meters.

[1035] Disable LL-07 Oiler Fault Detection

[10-36] Disable LL-12 Fault Detection (Drum Stall)

[1060] Fuser Temperature bond media adjustment. Allows the

adjustment of the Fuser Run Temperature: 300

° F

(149C) with 36 inch wide bond media.

Go to ADJ 10.1 Fuser Temperature.

[1062] Fuser Temperature vellum media adjustment: 294

°F

(146

°C). Go to ADJ 10.1 Fuser Temperature.

[1063] Fuser Temperature film media adjustment: 300

°F

(149

°C). Go to ADJ 10.1 Fuser Temperature.

[1101] Folder Status

[1401] Loopback Test for Remote Access Interface

[1402] Loopback Test for Controller Command / Status

[1403] Loopback Test for Finisher Port

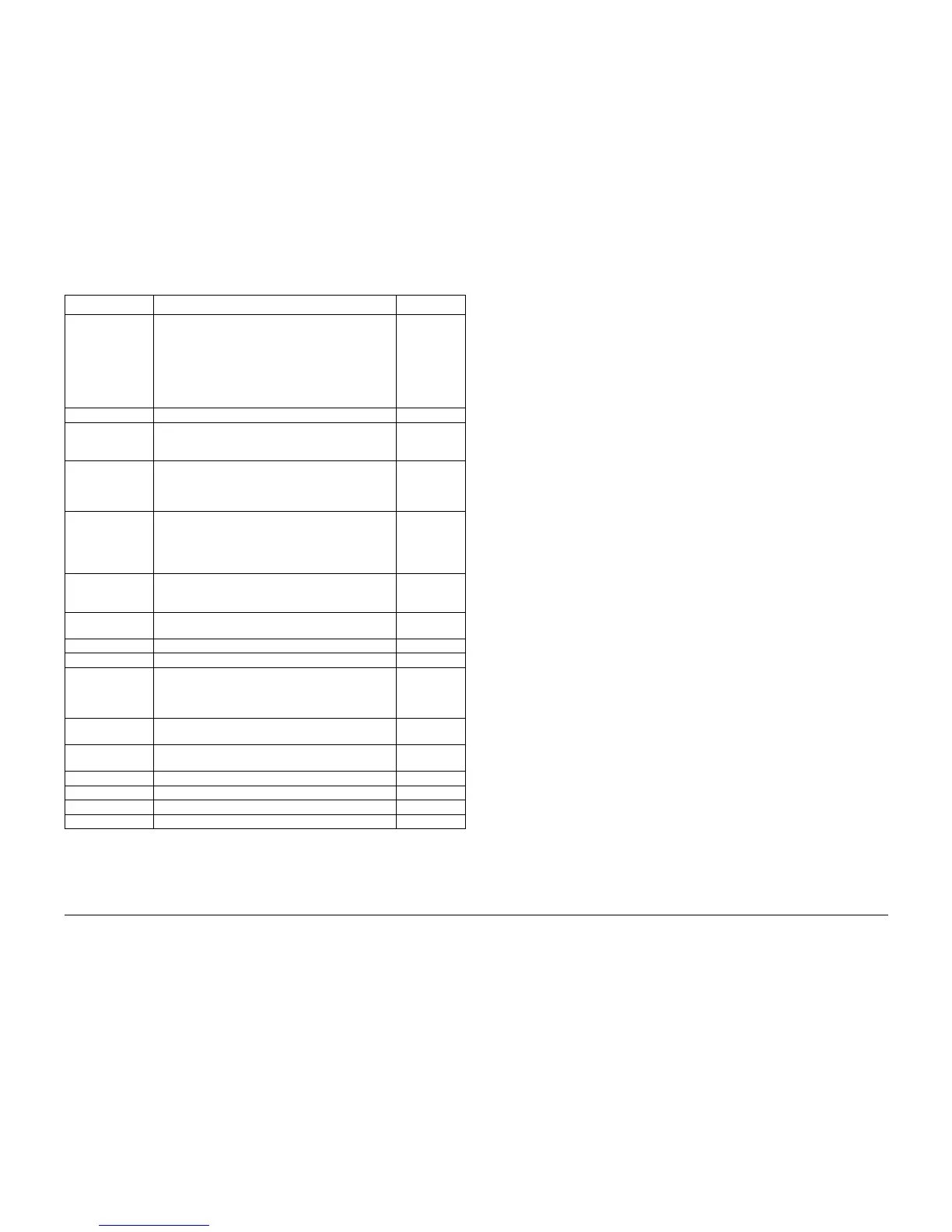

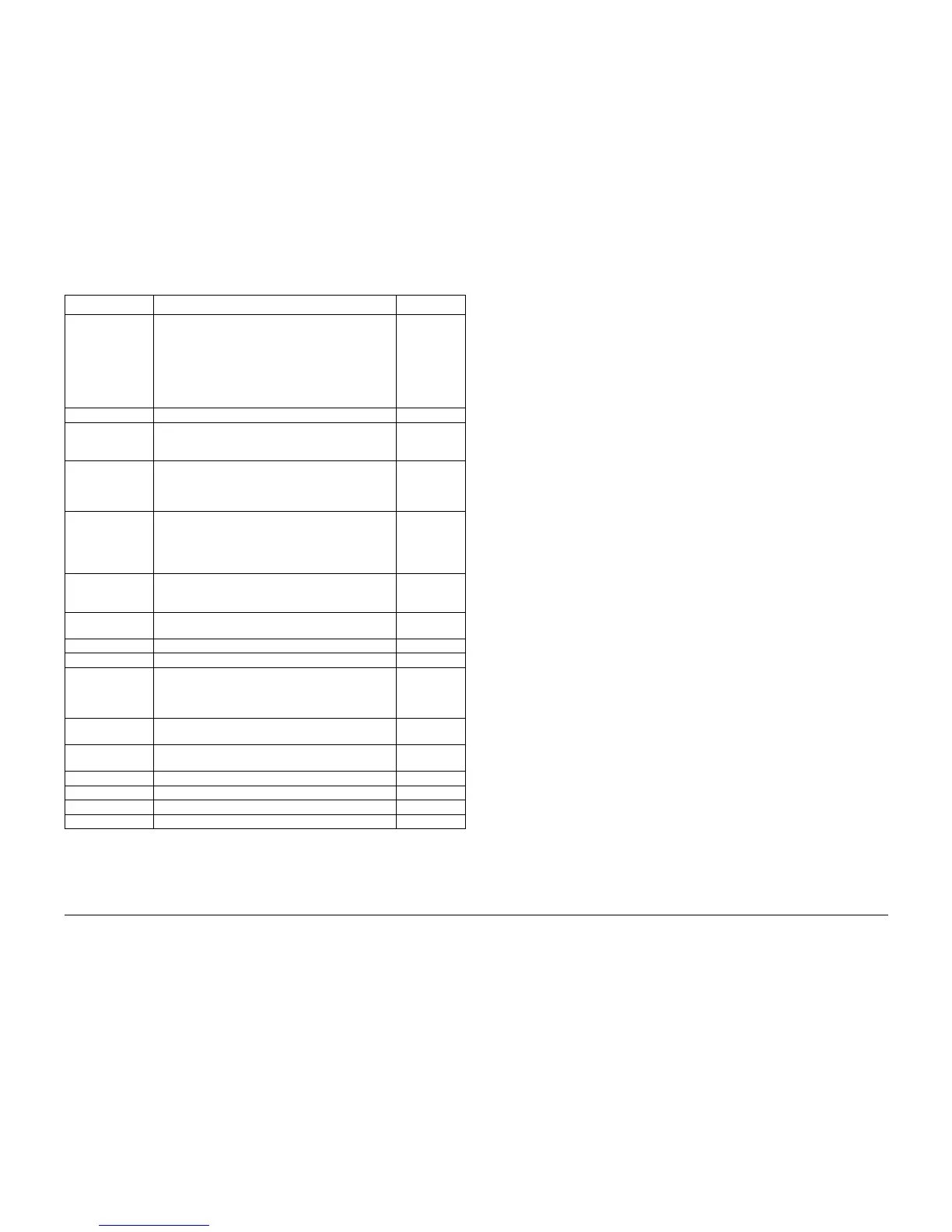

Table 1

Code Description Value

Loading...

Loading...