892-0000010B OM

122

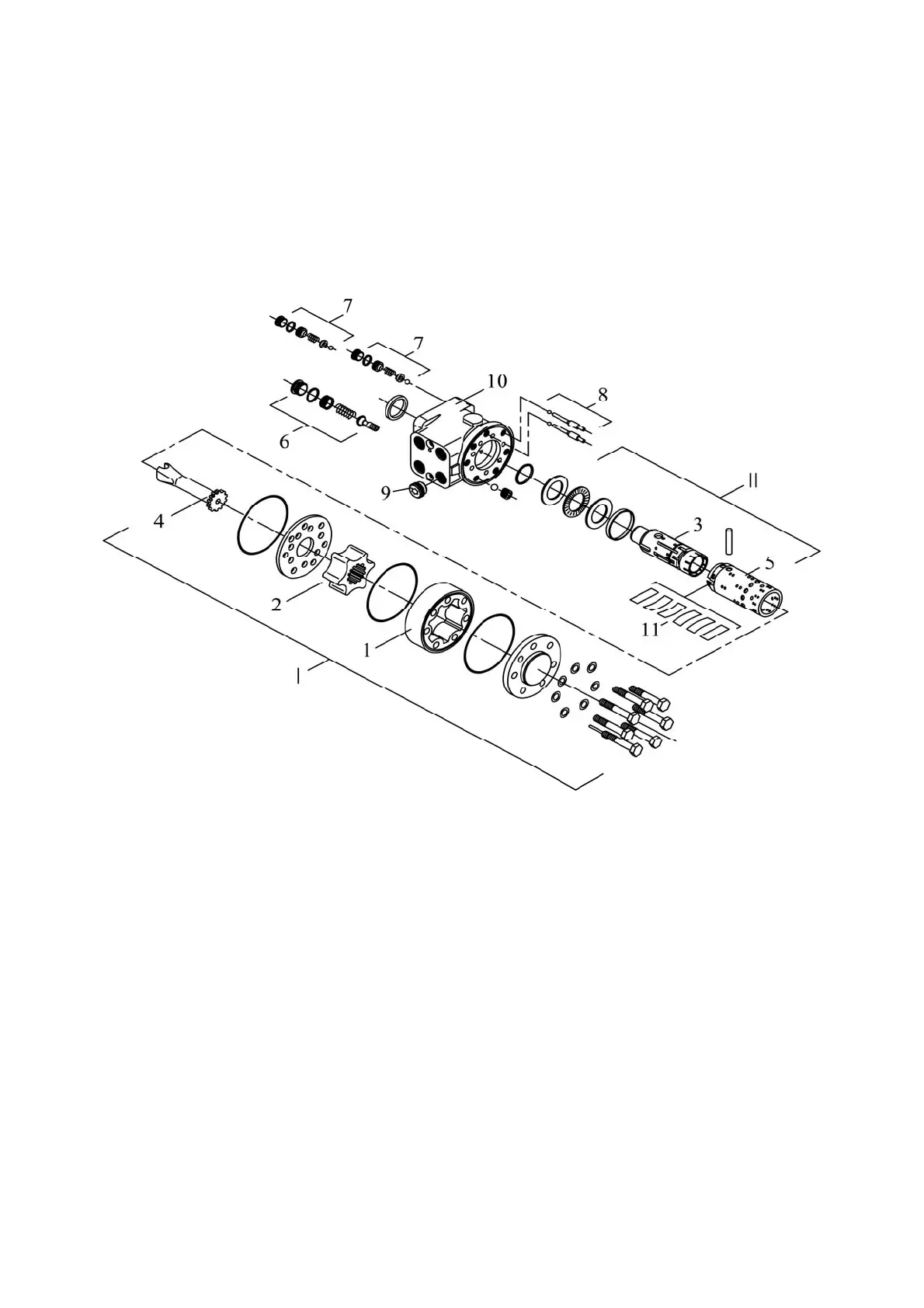

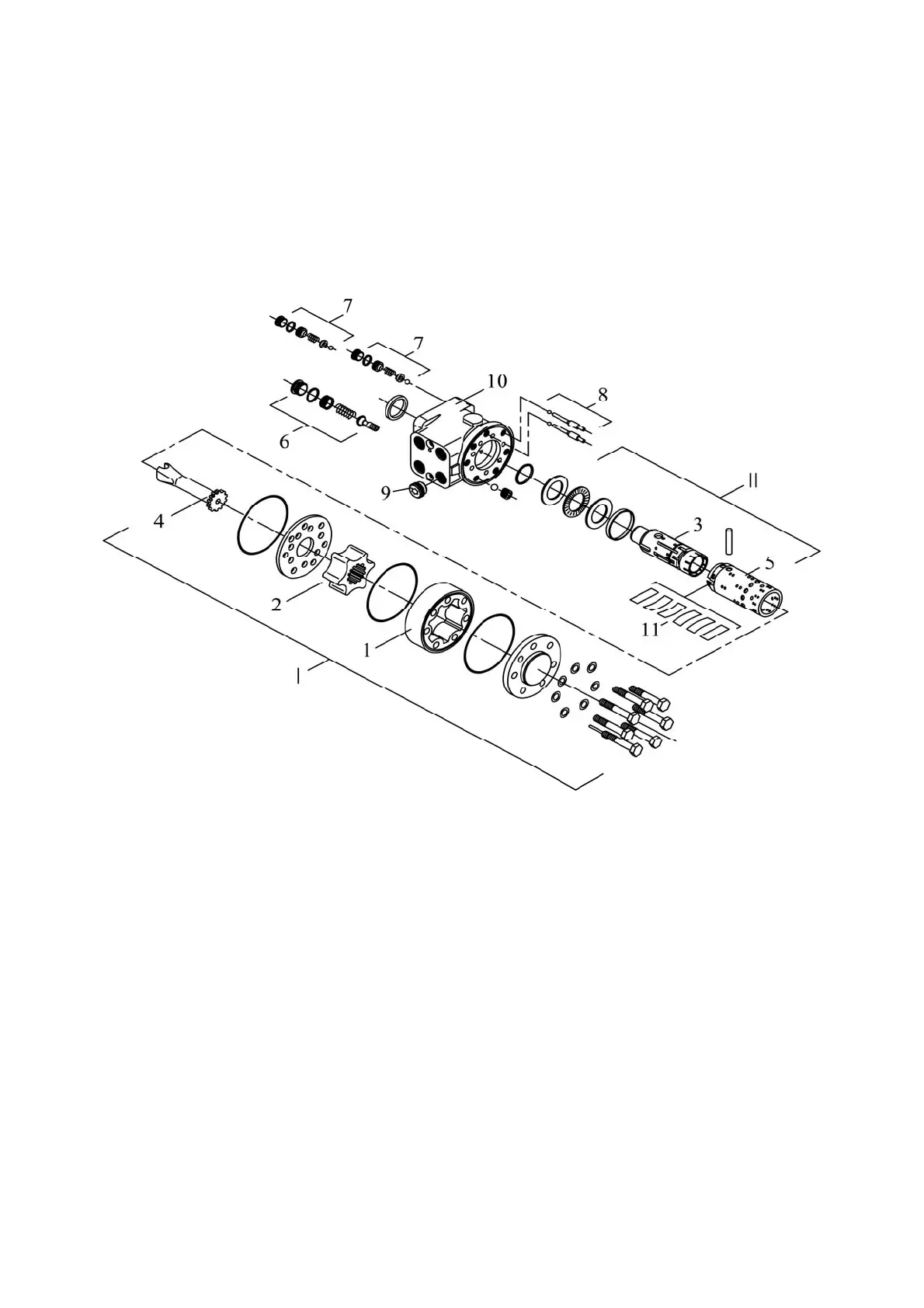

Safety valve 6 protects the pump and HSC hydraulic system from overload, limiting

the maximum pressure in the pressure line within the range from 14 to 15 MPa.

Anti-shock valves 7 (right and left) protect the tubes of the cylinder hydraulic lines

from peak pressures that occur when the steered wheels hit obstacles. The setting pressure

of anti-shock valves is from 20 to 21 MPa.

Anti-vacuum valves 8 (right and left) protect the HSC hydraulic system from vacuum

and cavitation when anti-shock valves are activated and allow oil to be supplied from one

cavity of the hydraulic cylinder to another when the dosing pump is running in the manual

control mode.

1 - stator; 2 - rotor; 3 - spool; 4 - cardan shaft; 5 - sleeve; 6 - safety valve; 7 – anti-shock

valves; 8 - anti-vacuum valves; 9 - check valve; 10 - housing; 11 - leaf springs; I - pumping unit; II -

distributor.

Figure 3.10.3 – Dosing pump

3.10.3 Steering hydraulic cylinder

The differential steering hydraulic cylinder is installed in front of the FDA-822 body

(Figure 3.10.1) or behind the FDA-72 body, and ensures the rotation of the tractor guide

wheels with the help of the steering linkage. The rod of the hydraulic cylinder is connected

to rotary lever 9 of the left wheel gear through conical pin 10, while the body of the hydraulic

cylinder is connected to bracket 13 mounted on the FDA body.

The hydraulic cylinder consists of body 5 (Figure 3.10.4), rod 6, piston 17, front cover

11, captive nut 12. The piston is mounted on the rod with nut 2, which is locked by punching

the belt into the grooves of rod 6. In cover 11, wiper 13, rod seals 14 and 15 and guide rings

16 are installed, eliminating friction of the rod and the cover. Combined seal 3 is installed on

the piston, which eliminates friction between the piston and the body sleeve. In the lugs of

the body and the rod, articulated spherical bearings 1 are installed, which have channels on

the inner ring for the lubrication of friction surfaces. In the Ts63 cylinder, the joints are closed

by bushings 19 and protective rubber boots 18 from contamination.

The joints are lubricated through grease fittings 12 (Figure 3.10.1) in the conical pins

10.

Loading...

Loading...