892-0000010B OM

274

6.4.7 General maintenance services

6.4.7.1 General guidelines

Carry out maintenance service operations, listed in subsection 6.4.7 as may be necessary

(i.е. when level sensor or dirtiness sensor responds).

6.4.7.2 Operation 62. Oil pressure adjustment in the engine lubricating system

Always look after the oil pressure value at the pressure gauge on the instrument

board. If the engine works at the rated speed and coolant temperature 85...95С, oil pres-

sure shall be at 0.25...0.35 MPa, the pressure value at the cold engine can be till 0.6 MPa;

If the lubricating system is intact (oil pipelines are leak-free, the safety valve in the oil

filter is intact etc.), but during the engine’s operation at the rated speed at the normal working

temperature of LC the pressure in the lubricating system, but if at rated engine rpm with

normal cooling liquid temperature the pressure exceed permanently the value of 0.35 MPa

or is always lower 0.25 МРа it is necessary to adjust oil pressure in engine lubrication sys-

tem.

Carry out the oil pressure in the lubricating system of the engine as follows:

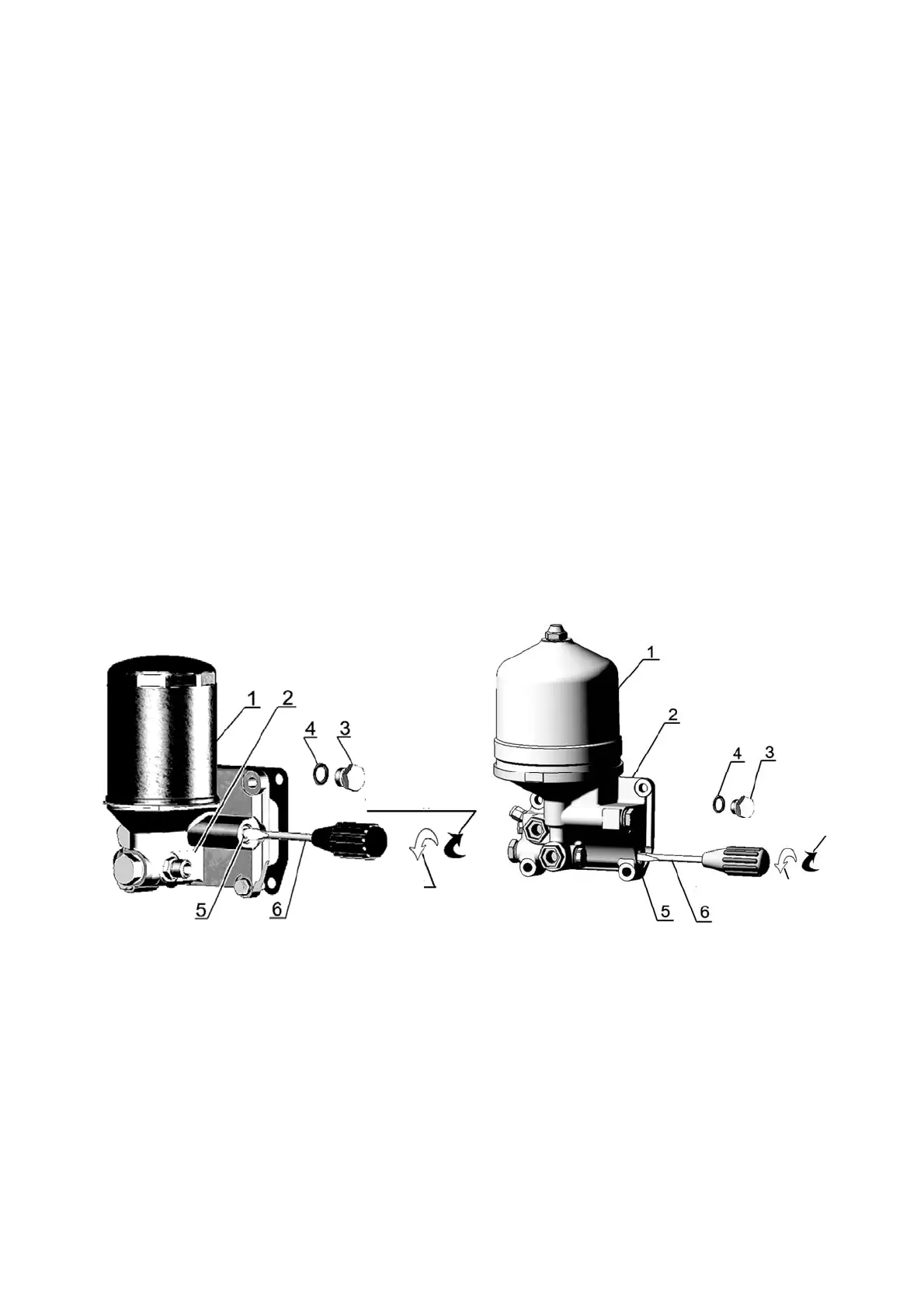

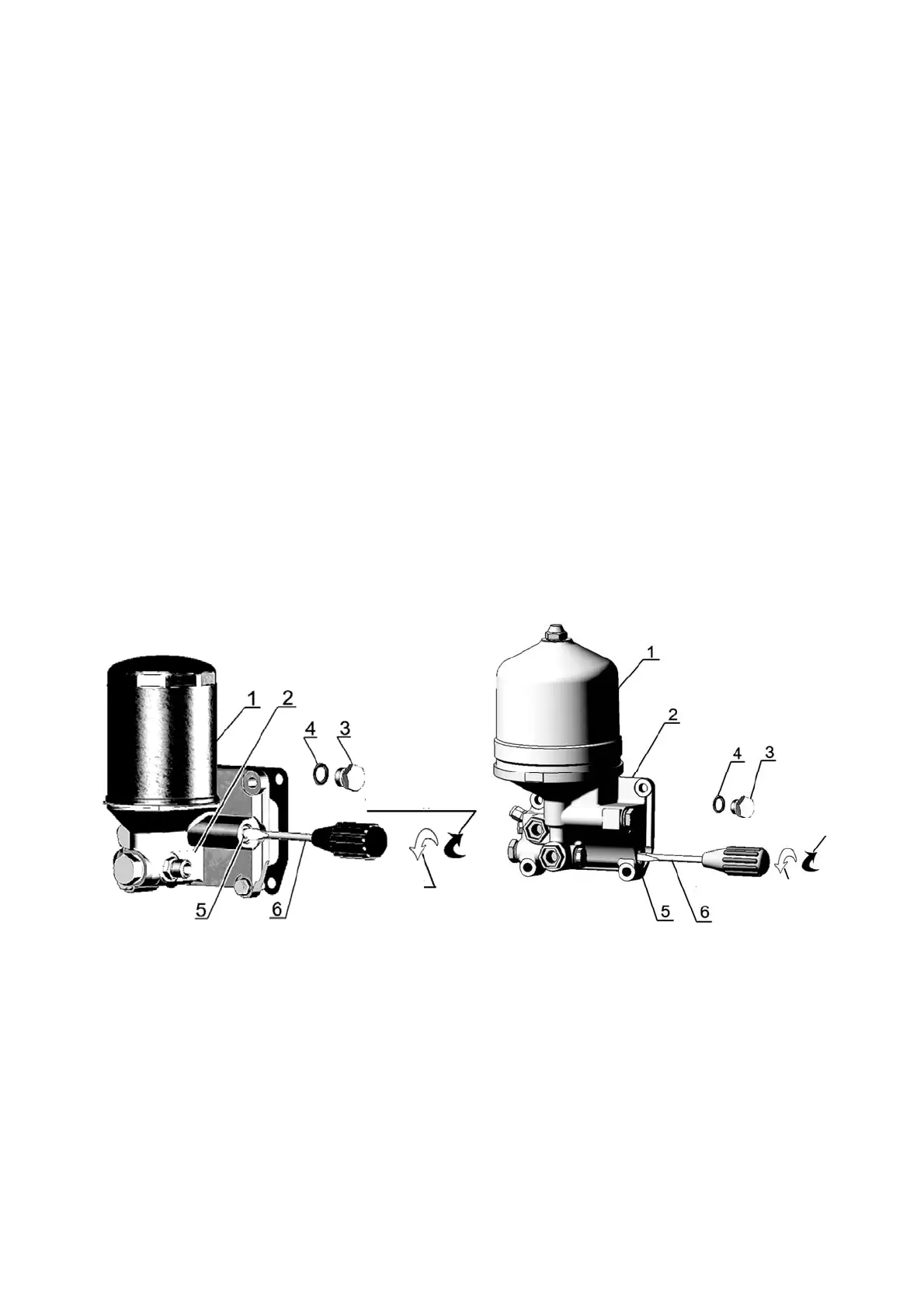

- unscrew plug 3 (Figure 6.4.53), remove gasket 4;

- in oil filter housing 2 channel turn adjusting plug 5 with a help of screwdriver 6 by

one turn to one or to another side to increase or to decrease the pressure (depending on

actual pressure);

- mount gasket 4 and screw plug 3;

- if necessary, repeat the above mentioned regulation measures.

IT IS FORBIDDEN TO PERFORM REGULATION WITH THE ENGINE RUNNING.

а) For tractors with full-flow b) For tractors with centrifugal

nonseparable oil filter oil filter

1 – full-flow nonseparable oil filter (centrifugal); 2 – filter housing; 3 – valve plug; 4 –

plug gasket; 5 – adjusting plug; 6 – screwdriver.

Figure 6.4.53 – Oil pressure regulation in engine lubricating system

Increase

ressure

Decrease

ressure

Increase

ressure

Decrease

ressure

Loading...

Loading...