892-0000010B OM

79

from the engine lubrication system. From the pneumatic compressor, oil is drained into the

engine oil sump.

To ensure the operation of the HSC, a gear pump is installed on the engine. The gear

pump is driven by a toothed transmission of the timing mechanism.

3.1.2 Engine air cleaning system

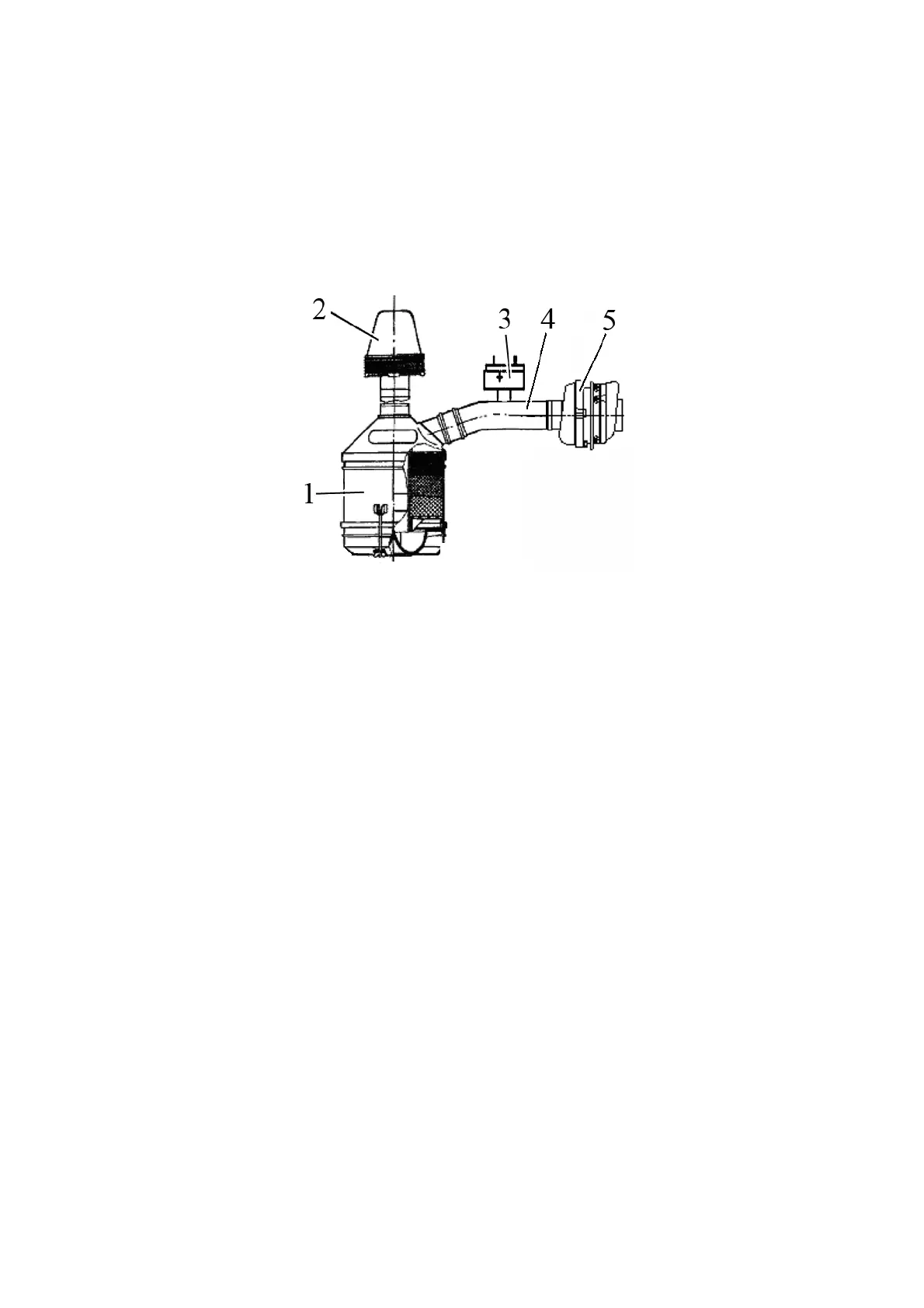

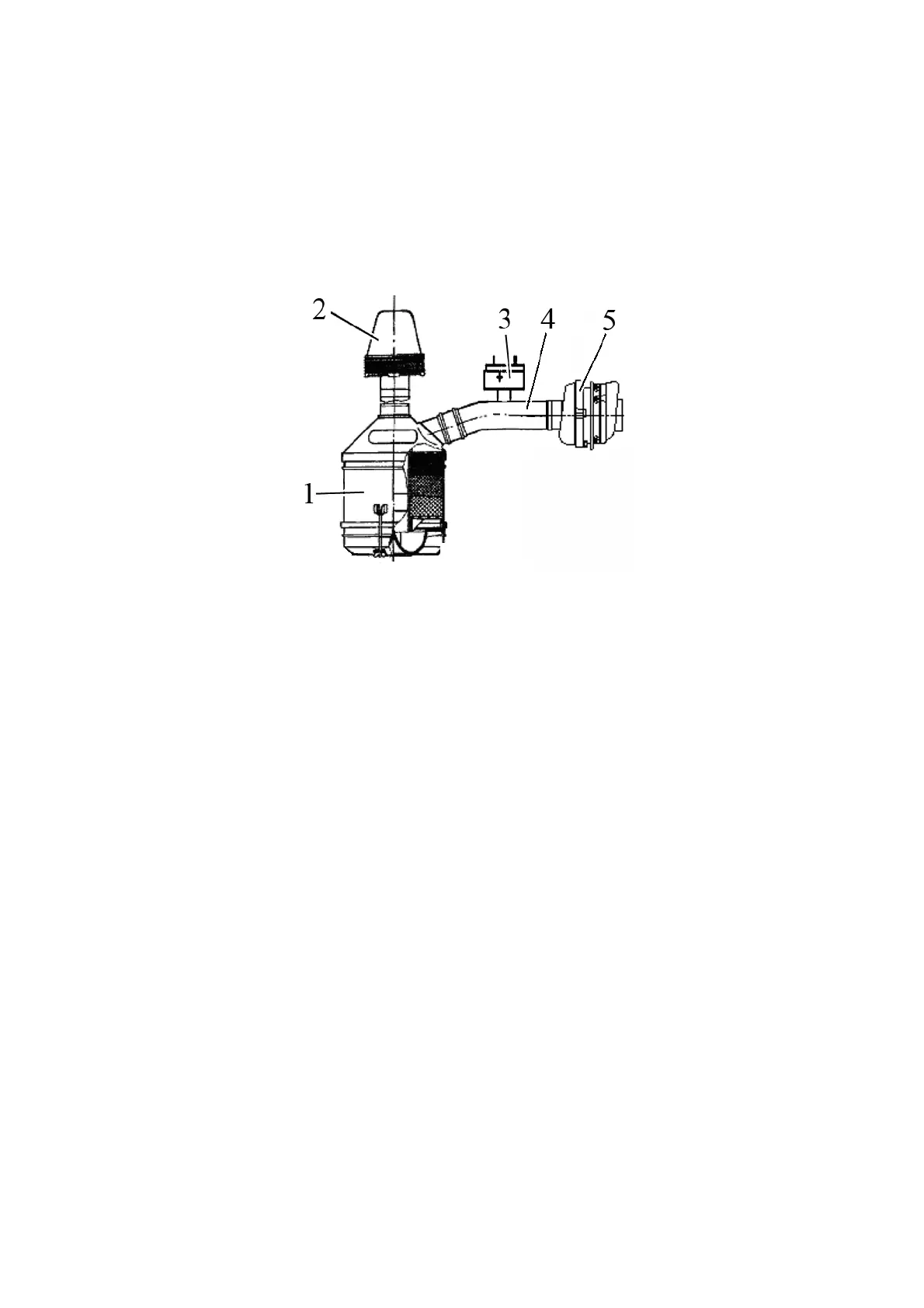

Elements of the air cleaning system for the engine of the BELARUS-892/892.2 tractor

are shown in Figure 3.1.4.

1 - air cleaner; 2 - monocyclone; 3 - air cleaner filter clogging sensor; 4 - air duct; 5 - en-

gine turbocharger.

Figure 3.1.4 - Engine air cleaning system

The BELARUS-892/892.2 tractors are equipped with inertial-oil air cleaner 1 (Figure

3.1.4) in which intake air is cleaned of dust passing through an oil bath and steel braided

filter elements. The air intake by the air cleaner is carried out through monocyclone 2, which

provides preliminary inertial air purification due to the tangential intake and centrifugal forces

arising from the helical rotation of air, relative to the axis of the monocyclone housing, dis-

charging large dust particles. Air is supplied to engine turbocharger 5 through air duct 4.

To warn of the clogging of the air cleaner filter, an indication is provided by means of

a warning lamp located in the pilot lamp unit of the dashboard. Electrical sensor for air

cleaner sensor clogging 3 is installed on air duct 4 and is triggered at a discharge of 7 kPa.

Loading...

Loading...