892-0000010B OM

299

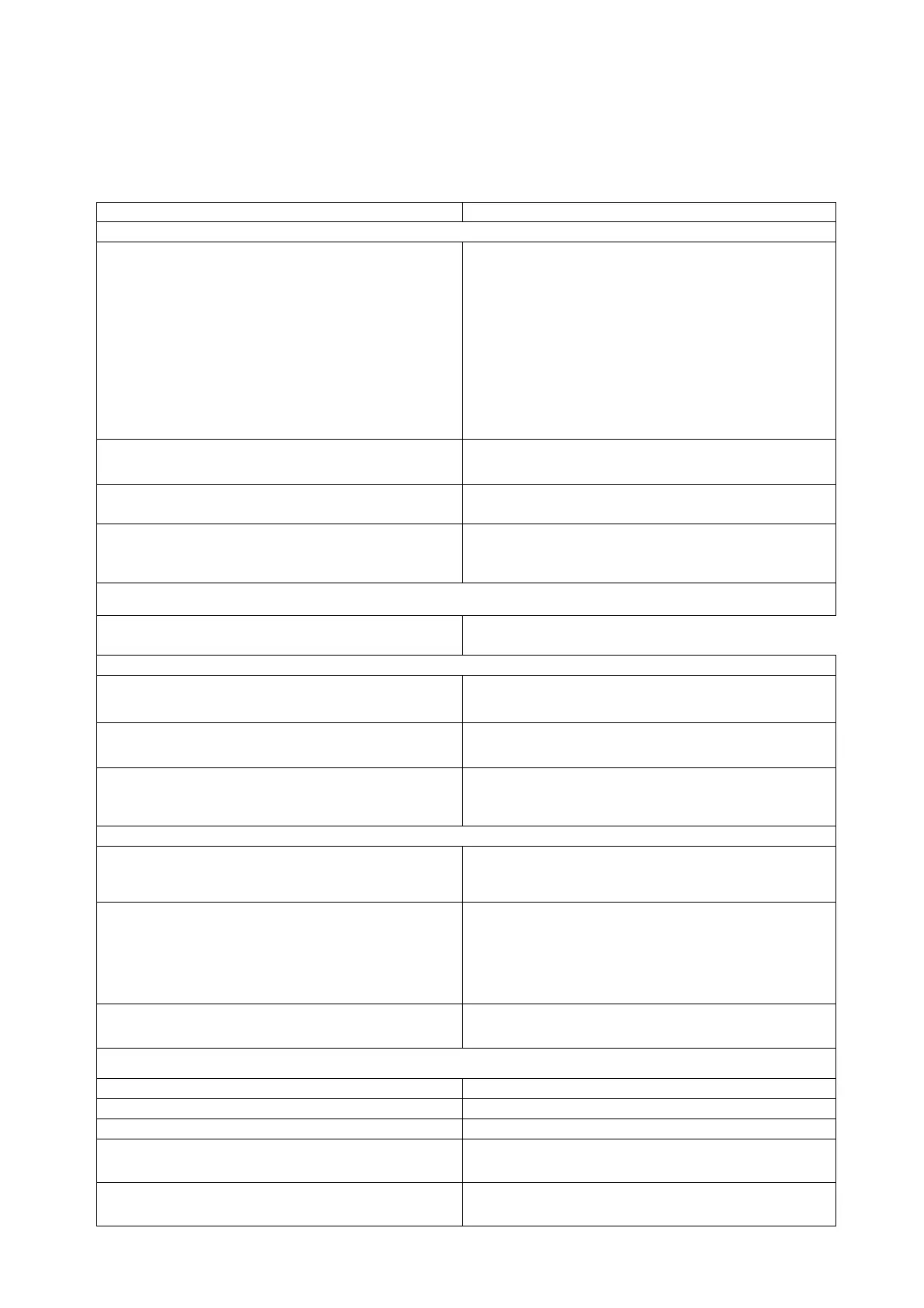

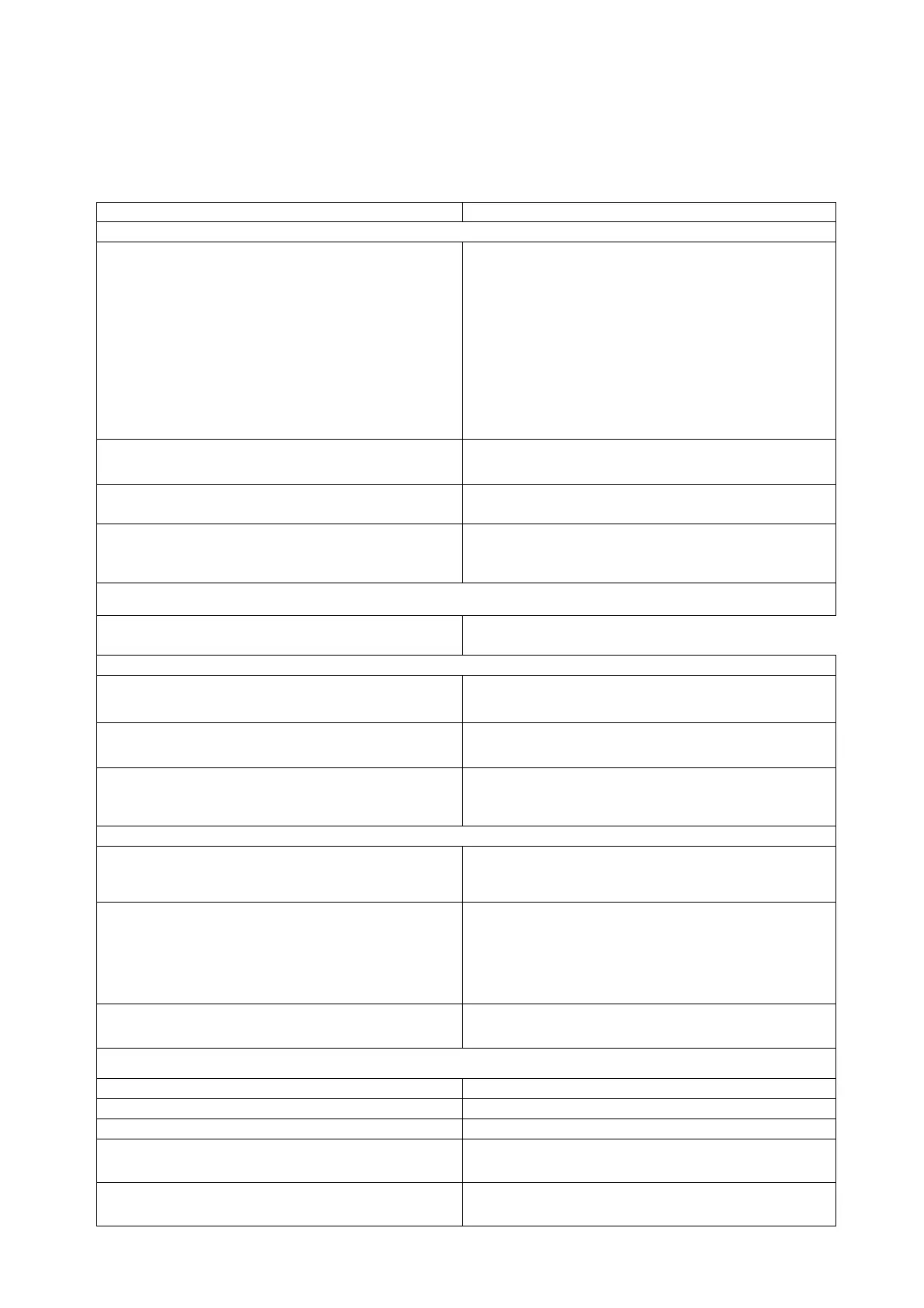

7.10 Possible failures of the hydraulic lift linkage and guidelines for troubleshooting

List of possible failures of the hydraulic lift linkage and guidelines for troubleshooting

are shown in Table 7.10.

Table 7.10

Defect, external manifestation, cause Troubleshootin

The hitch with an a

ricultural implement doesn’t lift

No pressure in the hydraulic system:

hanging of by-pass valve

Pull out valve parts, wash and install them

inside body. Valve should move freely.

clogging of safety valve

Disassembly safety valve, wash and rein-

stall it. Adjust pressure of valve actuation.

Insufficient quantity of oil in the tank.

Fill the tank with oil up to recommended

level.

Loss of pump capacit

Check pump capacity and replace it, if

necessar

Length of governor control tie-rod is out

of ad

ustment

Make adjustment

Weight of agricultural implement ex-

ceeds

allowable for tractor lift linka

e

Use agricultural implements agreed upon

with the manufacturer

No forced hitch lowering

Tie-rod of governor control is not correctly

ad

usted.

Make adjustment

Slow liftin

of hitch with an a

ricultural implement

ir ingress in the hydraulic system.

Find out ingress site and correct defect

Loss of pump capacit

Check pump capacity and replace it, if

necessar

Weight of an agricultural implement ex-

ceeds allowable for tractor lift linkage

Use agricultural implements agreed upon

with the manufacturer

Oil foamin

in the tank and splashin

throu

h breather

ir ingress in the system along inlet

manifold.

Tighten fastening and, if necessary,

replace gaskets of the suck -in manifold.

ir ingress through self-squeezed collars

of HLL oil pump of hitch hydraulic system

or

HSC system pump.

Check condition of self-squeezing collars

and replace them, if necessary

Too high oil level in the tan

Drain excessive oil down to recommended

Excessive oil heating during system operation

Insufficient quantit

of oil in the tank Fill tank with oil up to recommended level

Bent or crushed oil lines. Remove dents or replace oil line.

Disconnection of rod-t

pe distributor valve Replace rod-t

pe valve

Hanging of hydraulic distributor control

valve.

Push hydraulic distributor levers to position

“neutral” upon operation completion.

Hydraulic motors of agricultural implement

don’t match in consumption to pump supply

Use agricultural implements agreed upon

with manufacturer.

Loading...

Loading...