892-0000010B OM

186

The rear wheel track with the wheels of basic configuration 16/9R38 or 18.4R34(F-

11) is changed by moving the hub together with the wheel over the axle shaft and by replac-

ing the wheels from one sideboard to the other one.

To change the rear wheel track perform the following operations:

- put the tractor on a level ground, put the stops under the front and rear wheels, clean

the axle shafts from dirt;

- jack up the corresponding axle tube;

- loosen the wheel retaining nuts and remove the wheel;

- release by three full revolutions two tie bolts 1 (Figure 4.2.6) of the inserts 3 and 4

(one on each insert). The other bolts are to be screwed out. Remove blind plugs from the

holes for disassembly. Screw in the bolts of the inserts in the thread holes for disassembly;

- if it is impossible to squeeze the inserts out by means of disassembly bolts 1, fill

kerosene or other liquid penetrant in places where inserts are detached from the hub body,

wait for some time and then screw the disassembly bolts in, simultaneously knocking on the

hub body until the inserts fully squeeze out;

- move the hub to a required track (use the Table 4.2.5 to set the track “K” (Figure

4.2.3) by way of measuring the dimension “L” from the axle shaft end to the insert end face);

- screw the tie bolts out of the disassembly holes and screw them into the inserts.

Tighten the bolts with a torque of 360 to 450 Nꞏm in several stages until all bolts are tightened

with the required torque;

- mount the wheel on the hub, tighten the wheel retaining nuts with a torque from 300

to 350 Nm, place back the blind plugs;

- set the track for the other wheel by analogy;

- check and tighten the tie bolts and wheel retaining nuts after the first operation hour,

then after the first eight – ten operation hours and after every consecutive 125 hours of

operation.

ATTENTION: AFTER TIGHTENING THE BOLTS MAKE SURE THE END SURFACES OF

THE UPPER AND LOWER INSERTS DON’T JUT OUT WITH RESPECT TO EACH OTHER BY A

VALUE OF 1…2 MM!

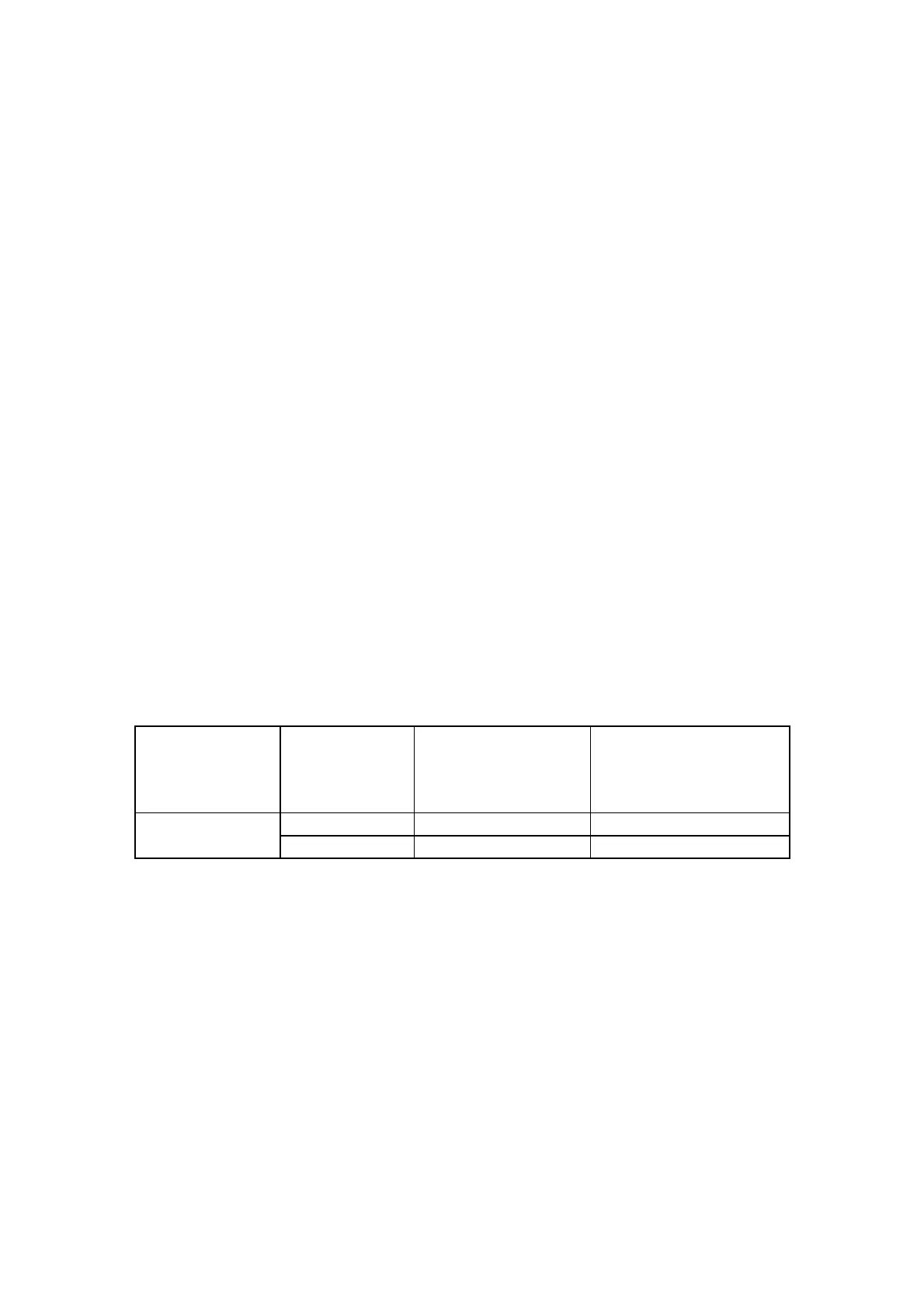

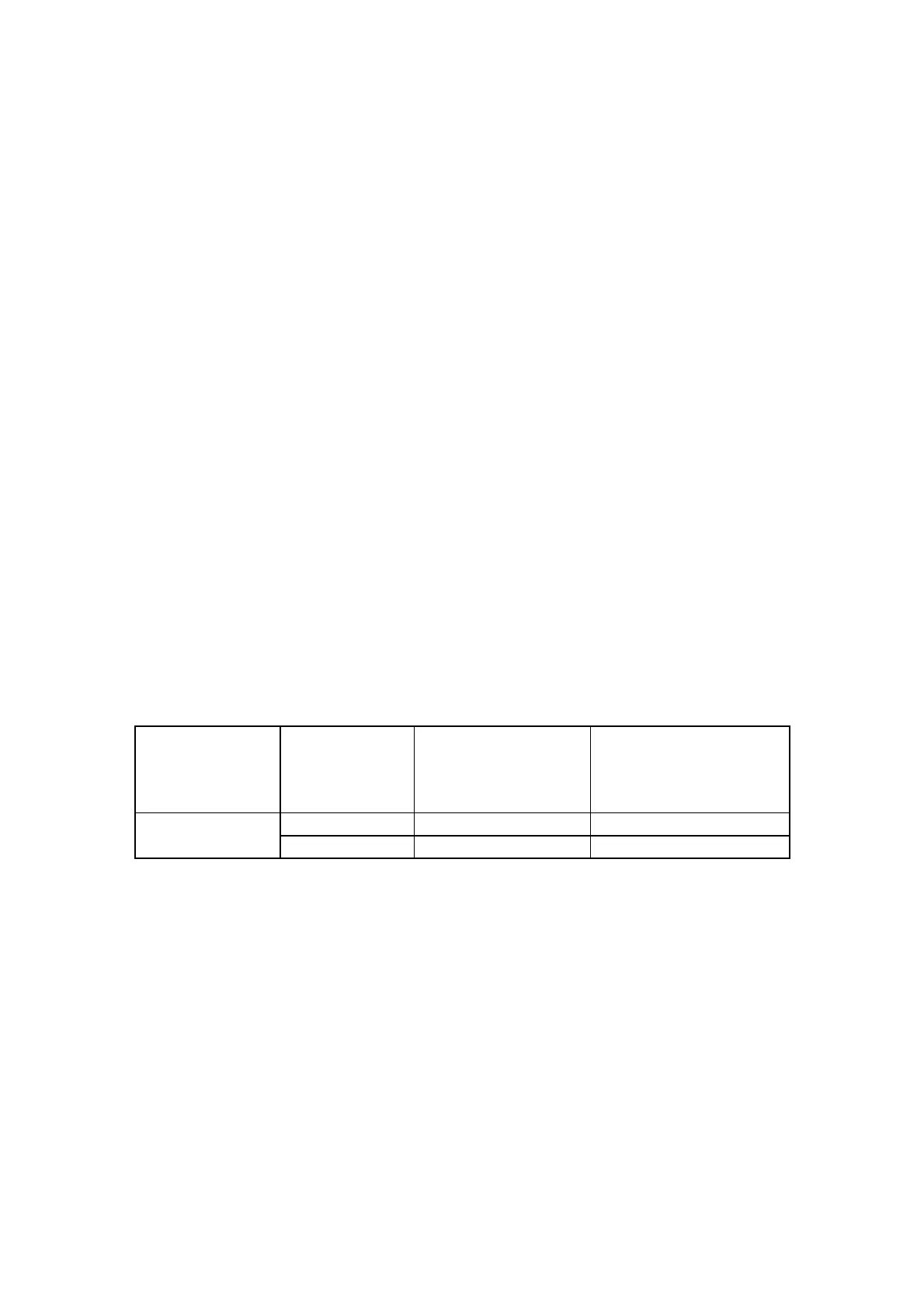

Table 4.2.5 – Rear wheel track installation variants (taper hubs)

Standard size of

tires

Variant

(Figure 4.2.3)

Dimension of track

“K”, mm

Mounting dimension

from the hub end face to

the axle shaft end “H”,

mm

18.4R34

А К(А) 1500…1600 69…19

B К(B) 1800…2100 183…33

ATTENTION: EX-WORKS DELIVERED REAR WHEELS ARE SET TO A TRACK UNDER THE

VARIANT A (FIGURE 4.2.3)!

4.2.10 Rear wheel twinning

With an aim to improve gripping properties of the tractor when coupled with heavy

agricultural implements on soils with low bearing capacity, rear wheel twinning with use of

spacers is provided.

To receive information on the rules of rear wheel twinning and operating restrictions

for the tractors with rear wheels twinned, please, contact your dealer!

Loading...

Loading...