892-0000010B OM

232

6.4 Scheduled maintenance servicing operations

6.4.1 Maintenance on a shift basis (SBMS) in every 8 – 10 hours of operation or per

shift

6.4.1.1 General guidelines

Every 8 – 10 hours of the tractor operation or at the end of a shift (whichever comes

first) perform the following operations:

6.4.1.2 Operation 1. Check of oil level in engine crankcase

Check oil level having put the tractor on a flat surface and not earlier than in 3 to 5 min

after the engine is killed, when the oil completely runs down to the crankcase.

To check oil level in the engine crankcase proceed as follows:

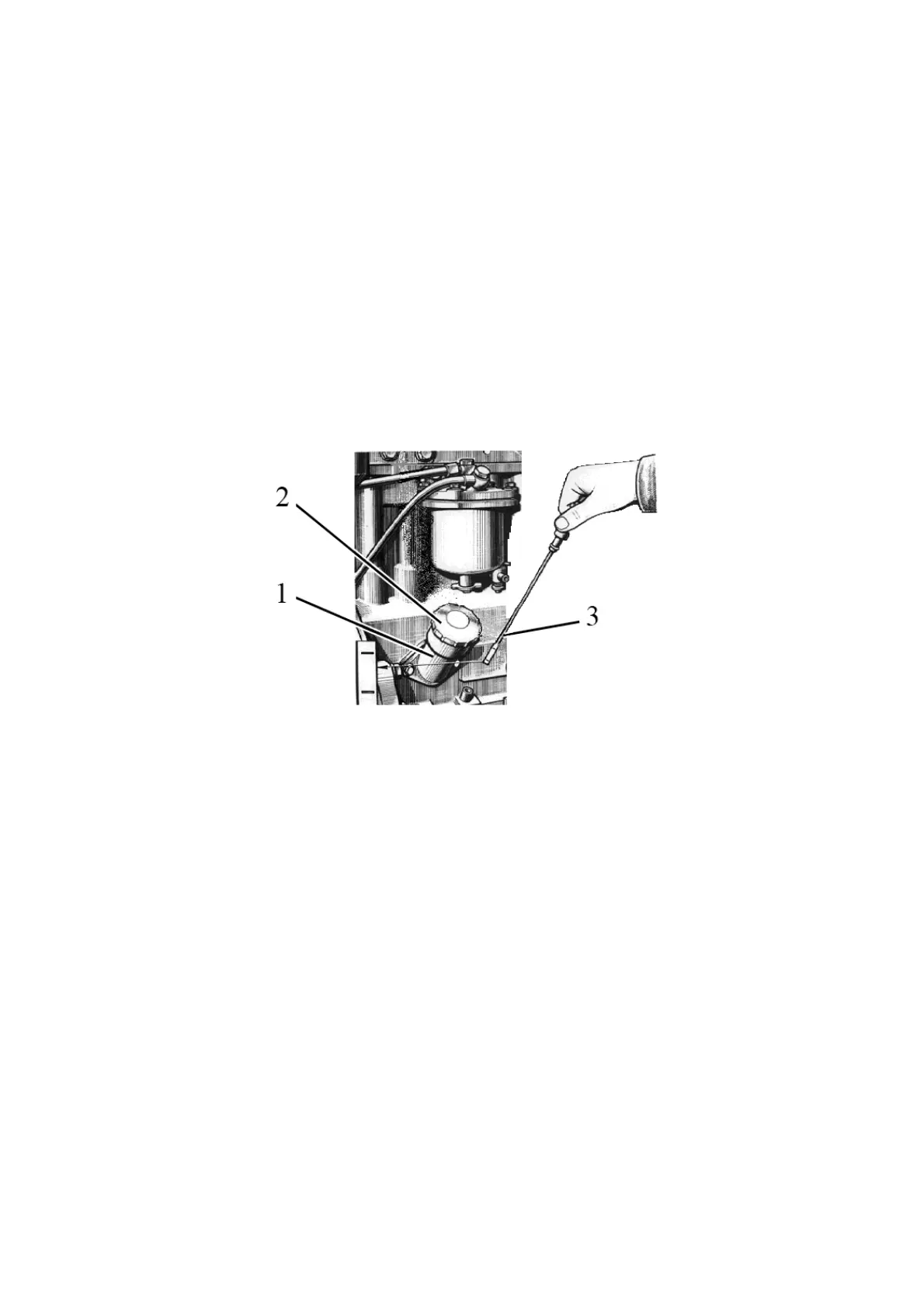

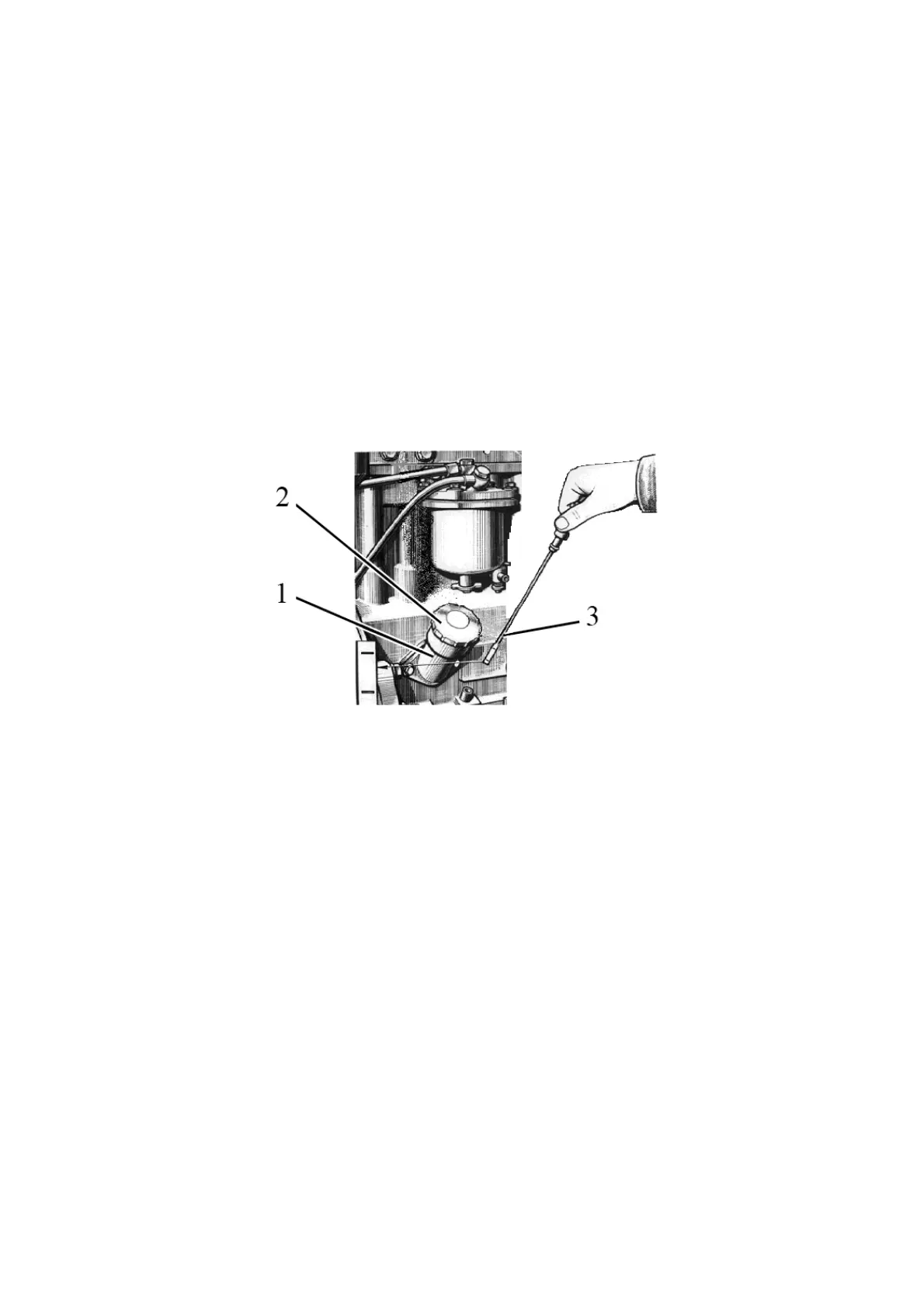

- take a dipstick 3 out (figure 6.4.1), wipe it clean and then put it back against the stop;

Take the dipstick 3 out and define the oil level. The level shall stay between the upper

and the lower marks of the dipstick. If required top up the oil through a neck 1, having re-

moved a cover 2.

- put the cover 2 back.

1 – filler neck; 2 – cover; 3 – dipstick.

Figure 6.4.1 – Check of oil level in engine crankcase

ATTENTION: DO NOT RUN THE ENGINE WITH THE OIL LEVEL BELOW THE

LOWER MARK ON THE DIPSTICK!

ATTENTION: DO NOT TOP OIL ABOVE THE UPPER MARK OF THE DIPSTICK.

THE OIL WILL BURN OUT CREATING ERRONEOUS IDEA OF LARGE OIL CONSUMP-

TION!

WARNING: BE CAREFUL TO AVOID THE CONTACT WITH NOT OIL!

6.4.1.3 Operation 2. Check of cooling liquid level in the engine cooling system

The coolant level in the engine cooling system shall be controlled by fullness of the

expansion tank 3 (Figure 6.4.2). The coolant quantity in the expansion tank shall stay at the

level of 20 to 30 mm from the expansion tank bottom to the upper edge of the clamp 2

fastening the expansion tank 3. If the coolant level is lower than 20 to 30 mm from the ex-

pansion tank bottom, open the plug 4 of the expansion tank, add the coolant to the expan-

sion tank up to the upper edge of the clamp 2 fastening the expansion tank.

Loading...

Loading...