892-0000010B OM

300

Table 7.10 finished

Defect, external manifestation, cause Troubleshootin

Agricultural implement is not maintained in transport position (lowering speed ex-

ceeds 20 mm per 10 min)

Tie-rod of governor control is not adjusted

correctly

Make adjustment, as given in section

“Adjustments”

Oil leakage along sealing rings of

cylinder piston or rod

Replace sealing rods of cylinder piston

Stop valve of the governor is not air-tight Adjust or replace the valve.

During draft control, change of ploughing depth exceeds agrotechnical norms, diesel

speed during overload drops

Speed correction valve is closed Turning hand wheel contraclockwise, increase

speed of automatic corrections.

Central link of the mounting unit is

set in the lower clevis hole.

Set central link in the upper clevis

hole, and if maximum ploughing depth

is not sufficient, set it in the middle

Power sensor is not correctly adjusted

Adjust power sensor, and then draft link

Draft link is not correctly adjusted Adjust draft link

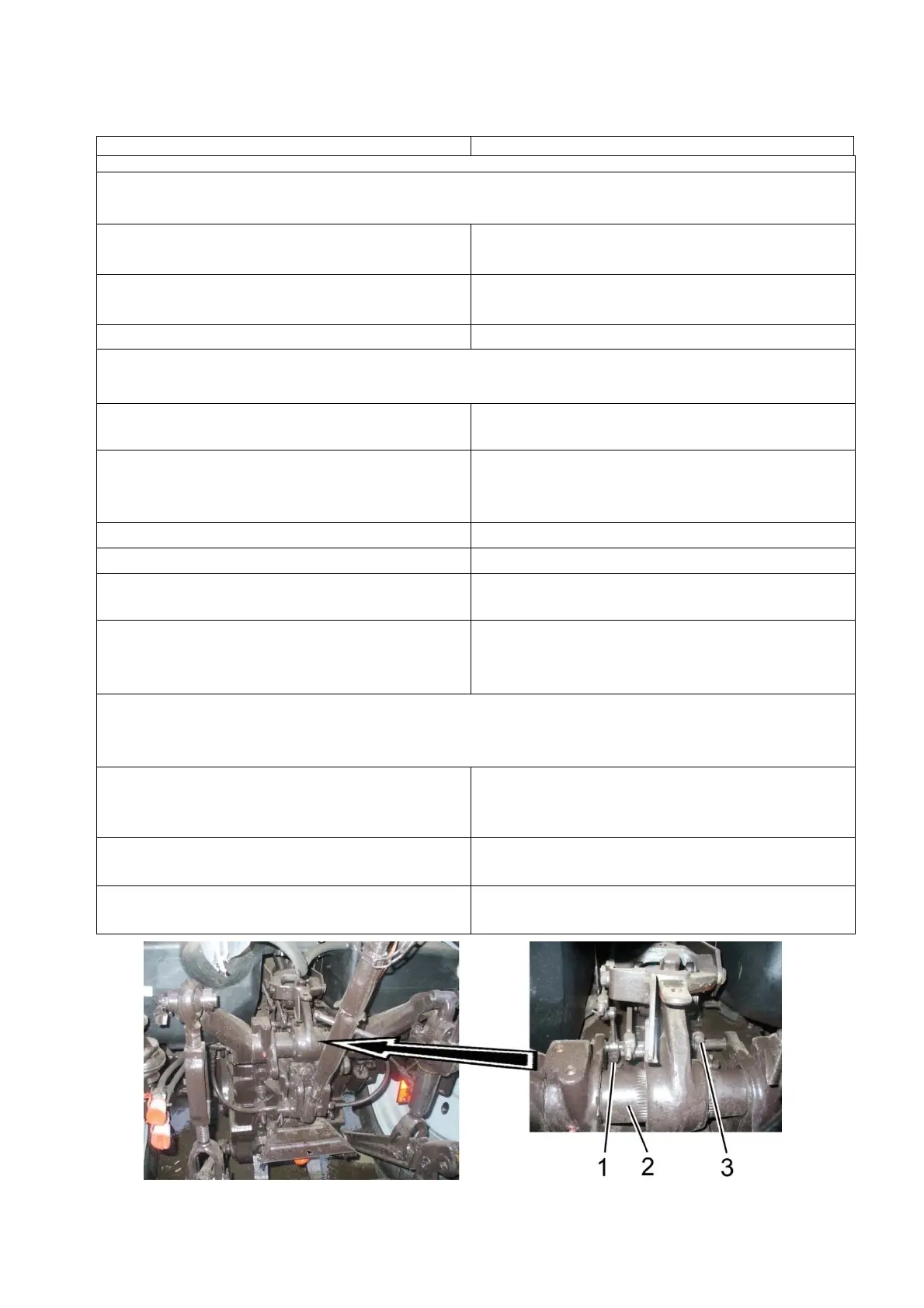

Loosened tightness of split hubs on the in-

termediate roller

Tighten bolts of levers’ hubs 1.3 (Figure

7.10.1) on the intermediate roller

Broken holes on the fixed member and

frame of plough, connected with brace,

insufficient rigidity of plough frame

Repair the plough to provide rigidity of

frame and its coupling with fixed member

Control handle doesn’t return on its own from position “lift” to position “transport

neutral”

Jamming in coupling of control with draft

control unit

Remove jamming, scrape bright surfaces of

oint connections from corrosion traces, put

grease, if required

Bolt of fixing spring on the control

handle is too tight

djust spring tension of the fixing element on

the control handle

Tie-rod of regulator control is not correctly

adjusted

Adjust length of tie-rod

1,3 – bolts of levers’ hubs; 2 – RLL shaft

Figure 7.10.1 Tighten bolts of levers’ hubs on the intermediate roller

Loading...

Loading...