892-0000010B OM

190

End of Table 4.2.7

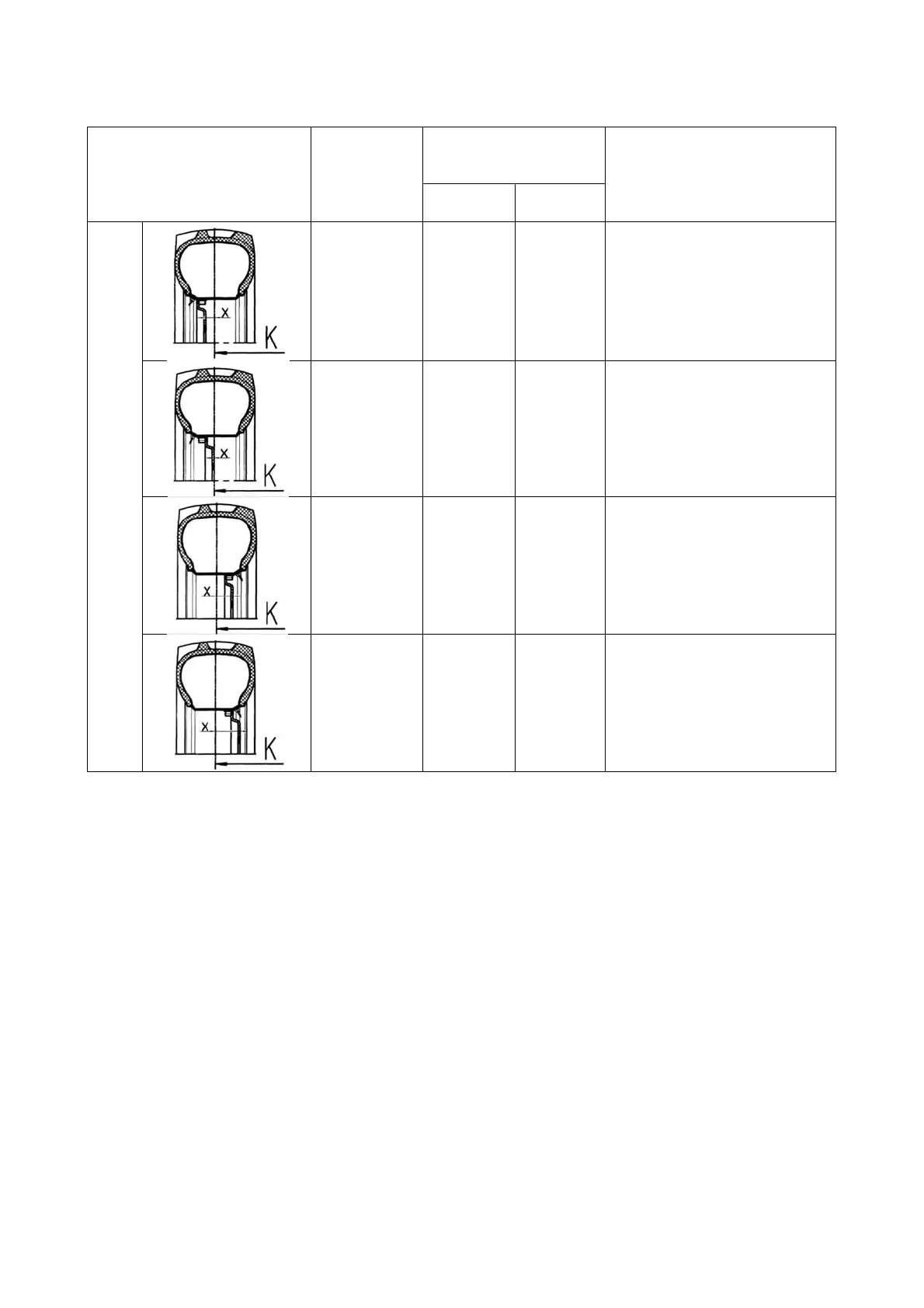

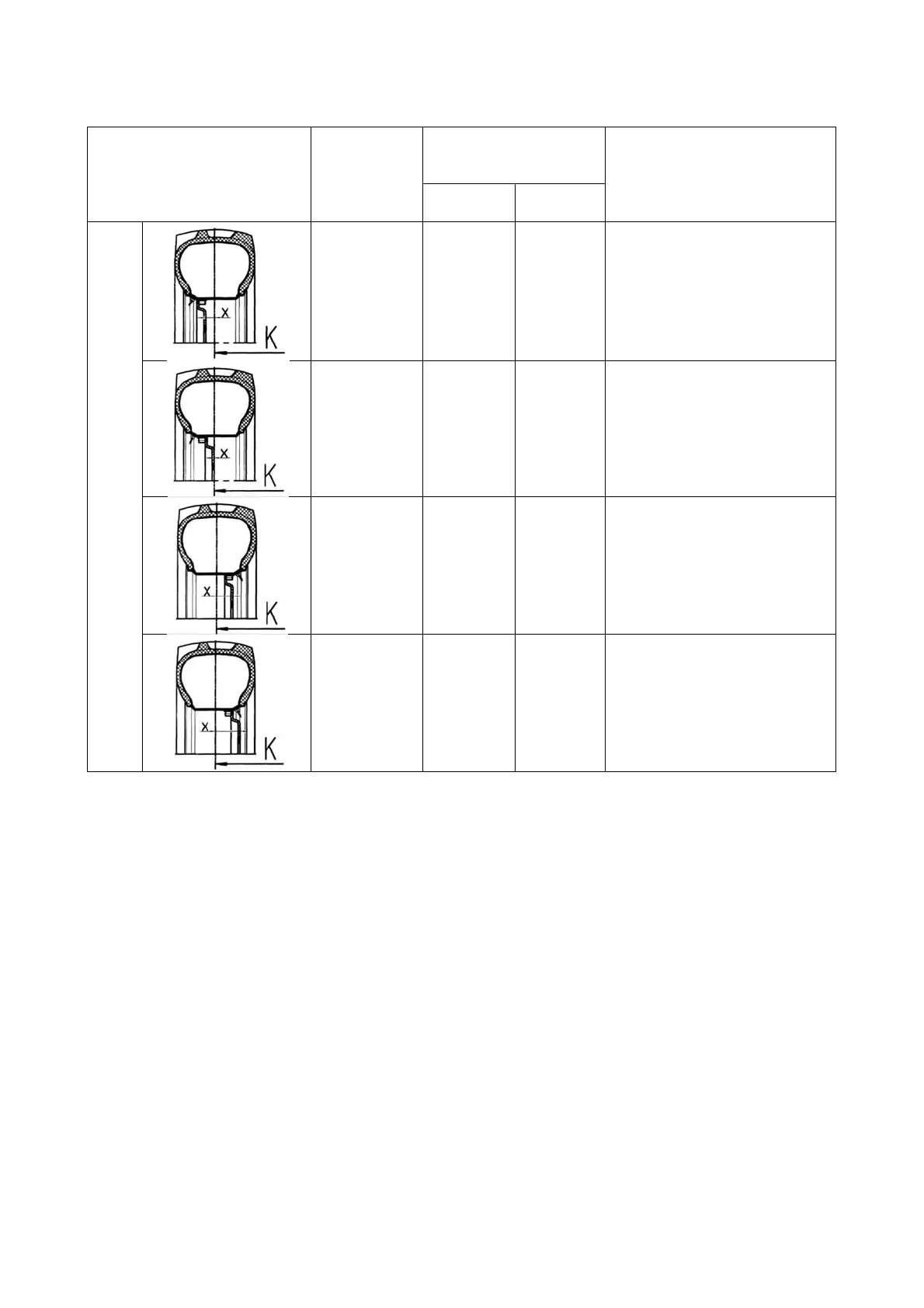

Variants of mounting the

disk and the rim

Disk offset Х,

mm

Tractor track

К, mm

tire 360/70R24

Description of mounting

method

Short

beam

Long

beam

Displacement of the disk and the rim

+56 1585 1705

The disk mates with the sup-

port outer surface.

+6 1685 1805

The disk mates with the sup-

port inner surface.

-102 1900 2020

The rim is turned by 180°.

The disk mates with the sup-

port inner surface.

-152 2000 2120

The rim is turned by 180°.

The disk mates with the sup-

port outer surface.

To set a required track proceed as follows:

- brake the tractor using the parking brake. Put stop members at the front and at the

back of the rear wheels;

- jack up the tractor front part (or front wheels one by one), ensuring clearance between

the wheels and the ground;

- to obtain the track by displacing the wheel from one sideboard to the other one without

changing disk position with respect to the rim, unscrew the nuts fastening the wheel disk to the

gear group flange, take the wheels off and change from one sideboard to the other one,

- to obtain the track by changing disk position relative to the rim with the wheels taken off

the tractor, unscrew the nuts fastening the wheel rim to the disk and depending on the track

required, set mutual arrangement of the rim and the disk as shown in the diagram in Table

4.2.7.

Mounting the wheels make sure the wheel rotation direction coincides with the direction

of an arrow on tire side.

The tightening torque for the nuts attaching plates to the gear group flanges shall make

200 to 250 Nm;

The tightening torque for the nuts attaching plates to the rim brackets shall make 180 to

240 Nm.

ATTENTION: AFTER YOU HAVE MOUNTED THE WHEELS CHECK NUTS FOR TIGHT-

ENING AFTER THE FIRST OPERATION HOUR, AFTER 10 OPERATION HOURS AND EVERY

125 HOURS OF OPERATION!

ATTENTION: AFTER YOU HAVE CHANGED THE FRONT WHEEL TRACK CARRY OUT

CHECK AND ADJUSTMENT OF FRONT WHEEL TOE-IN. BEFORE CHECKING THE TOE-IN

MAKE SURE TO CHECK AND, IF NECESSARY, ADJUST PLAY IN STEERING JOINTS!

Loading...

Loading...