892-0000010B OM

208

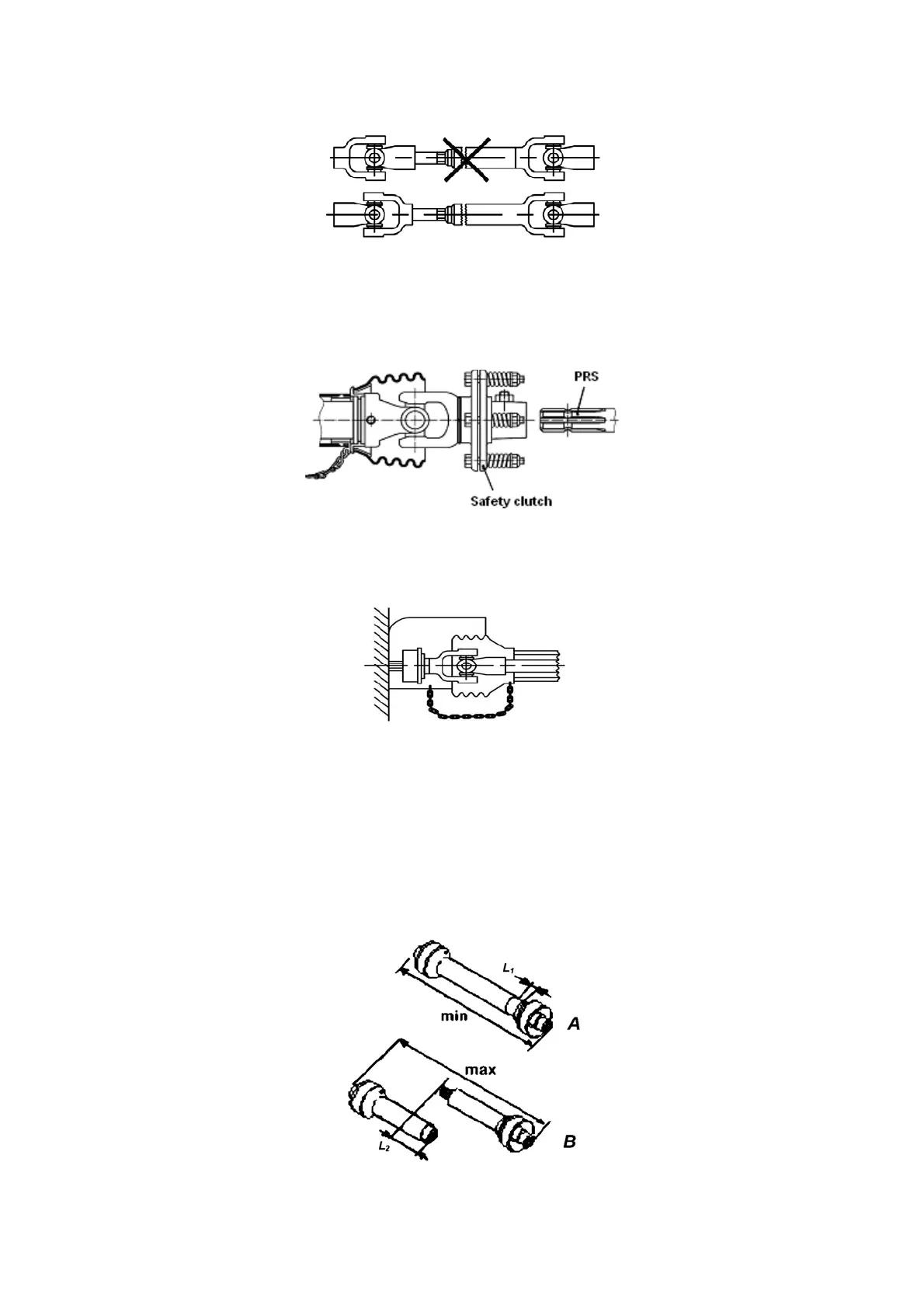

5. The implement cardan shaft end yoke from the side of PTO shaft and PRS shall

be in the same plane as indicated in Figure 5.6.1.

Figure 5.6.1 – Cardan shaft mounting scheme

6. Safety clutch, as indicated in Figure 5.6.2, shall be installed only from the side of PRS of

the drive of the implement coupled, other method of mounting will not ensure the excess of

timely protection of the tractor PTO shaft from the maximum permissible torque. After

lengthy downtime check the implement safety clutch technical condition.

Figure 5.6.2 – Safety clutch mounting scheme

7. Mounting of the cardan shaft with guard housing together with PTO shaft and PRS

protective devices, with retaining chains both from the side of the PTO shaft and of the PRS,

as indicated in Figure 5.6.3, ensures cardan joint safety.

Figure 5.6.3 – Safety cardan shaft mounting scheme

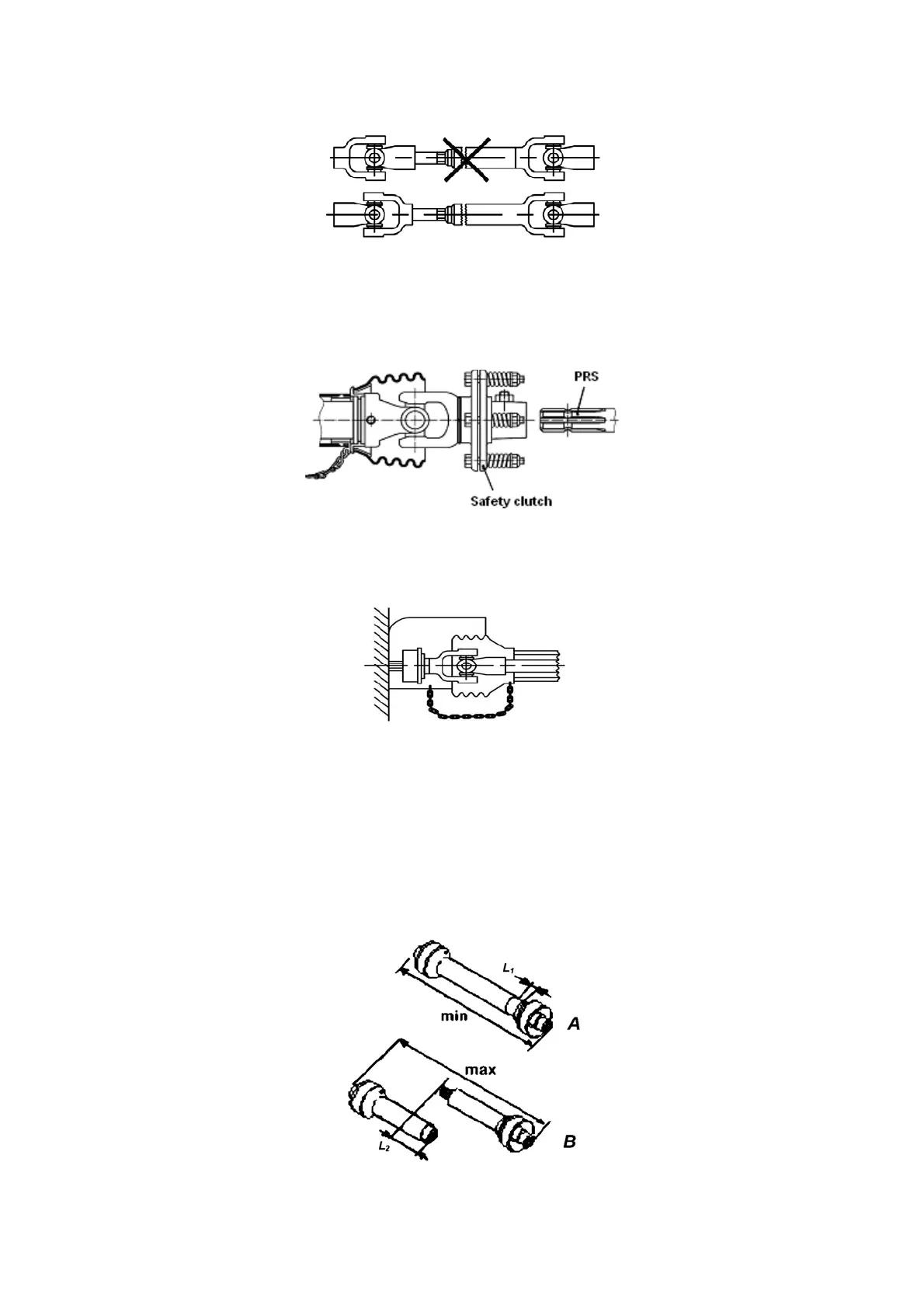

8. When the cardan shaft is used for the first time it is necessary to check the cardan

shaft length, and to adjust it to the operating conditions with BELARUS-892/892.2 tractors

when needed. For more detailed guidelines on cardan shafts see the technical documenta-

tion enclosed. Contact the cardan shaft manufacturer when needed.

9. The length of the cardan shaft maximum driven apart (which is permitted for oper-

ation) shall be of such type when the one part of the cardan shaft enters another for not less

than L

2

=150 mm. If the value is below L

2

=150 mm (Figure 5.6.4, view А) the cardan shaft

must not be operated. Sufficiency of overlapping L

2

can be checked by rotation or lifting of

the implement coupled.

Figure 5.6.4 – Choice of the cardan shaft length

Loading...

Loading...