892-0000010B OM

234

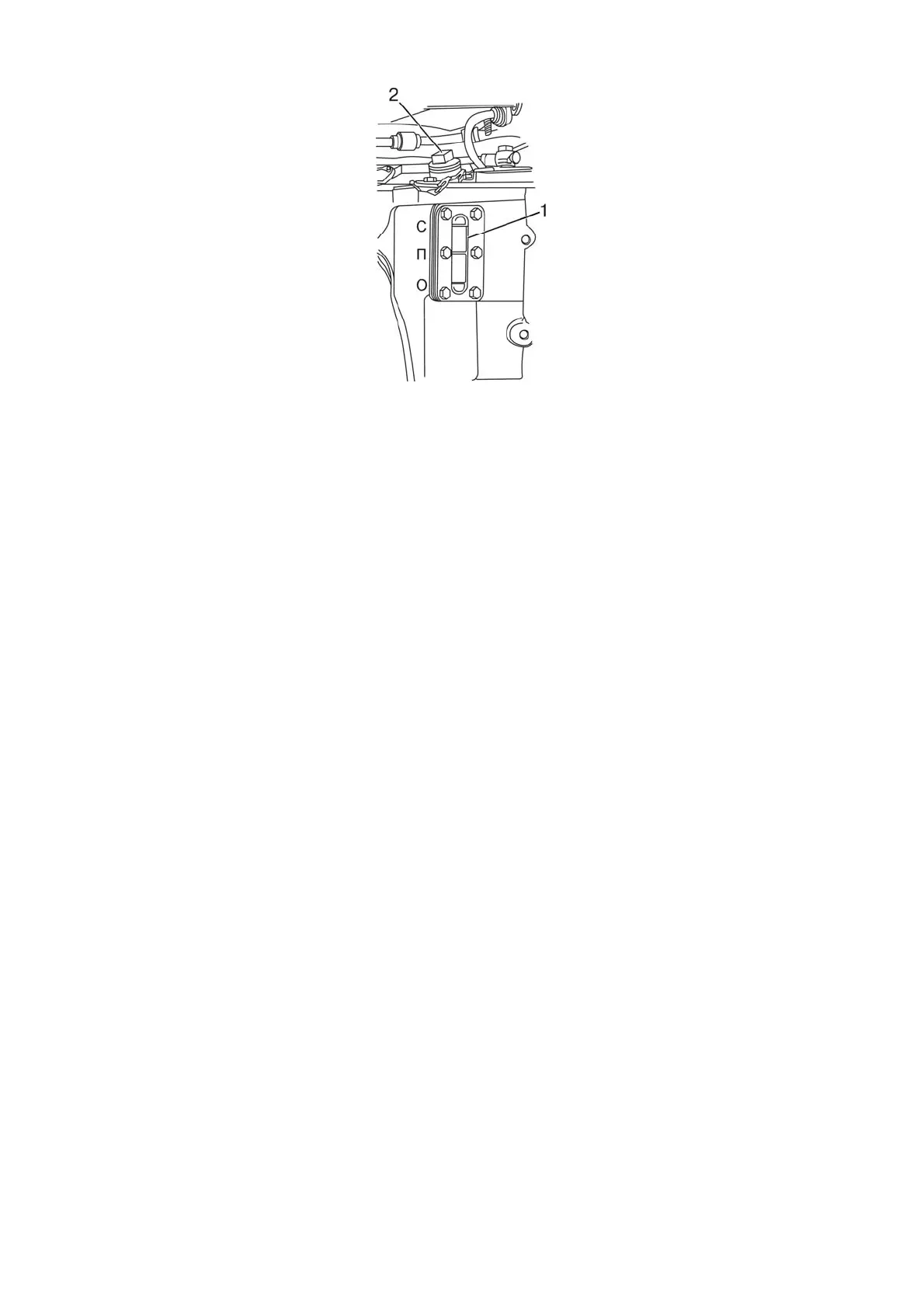

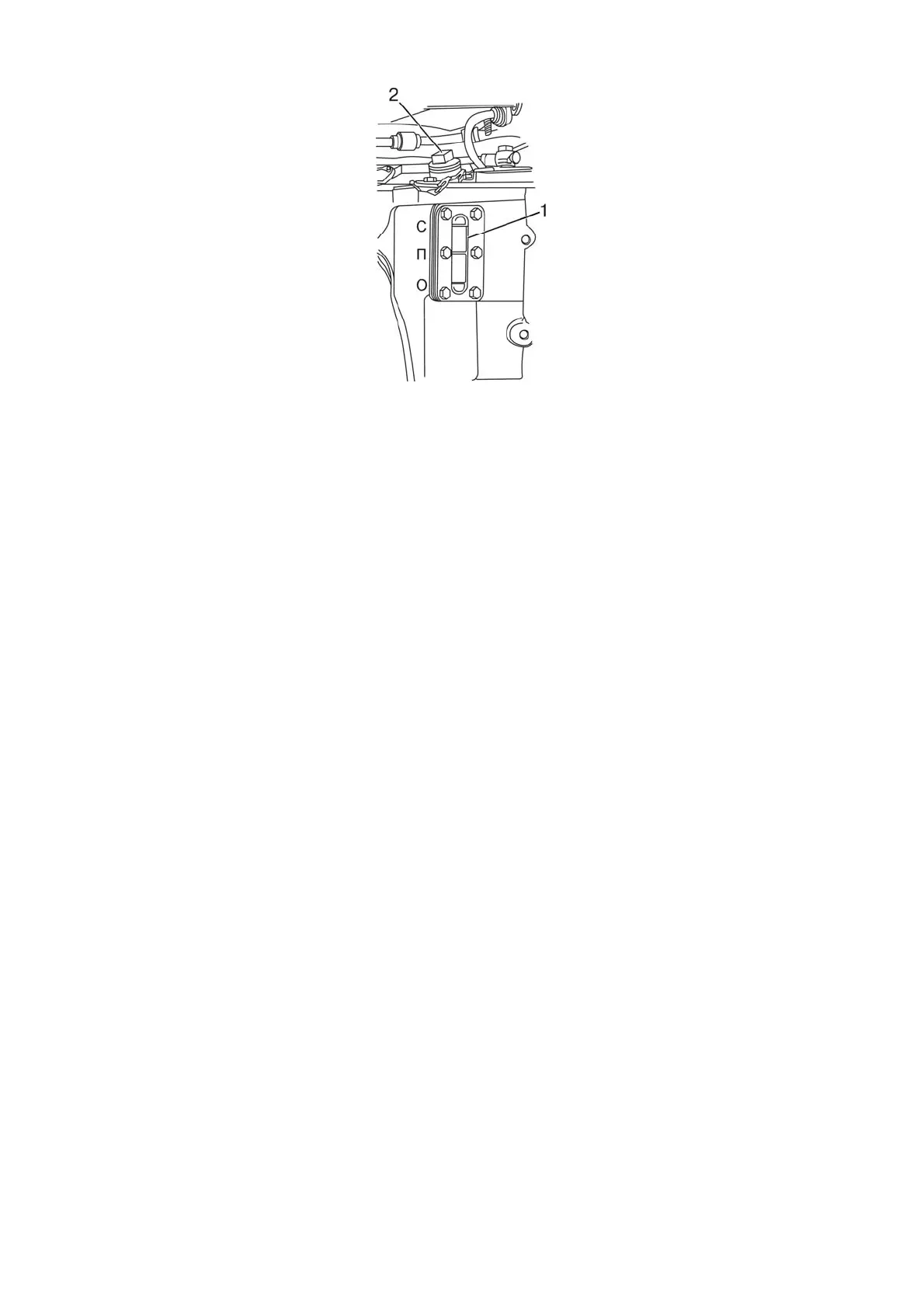

1 – mark of oil level; 2 – plug of oil filler outlet.

Figure 6.4.3 – Check of oil level in HLL and HSC integrated tank

ATTENTION: OIL LEVEL CHECKING OPERATIONS IN THE COMBINED TANK OF

HLL AND HSC SHALL BE CARRIED OUT ONLY WITH THE RETRACKED RODS OF RLL

HYDRAULIK CYLINDERS, AND CYLINDERS OF THE IMPLEMENTS COUPLED WITH

THE TRACTOR!

6.4.1.5 Operation 4. Check of tires state

Carry out inspection of outside appearance and conditions of the tires in order to

detect faults or objects getting stuck in the tires (tacks, rocks and etc.,). If necessary clear

the tires of the foreign objects. In case the tires have defects going up to the tire fabric or

cracks, going through the whole tire thickness, dismount the tire and send it to the special

repair workshop for retreading. If the tires have defects is beyond repair, replace the tire. De-

fective tire shall be sent to recycling.

6.4.1.6 Operation 5. Inspection of hydraulic system components

Carry out inspection of the tractor hydraulic system components, when the conden-

sation and downflows are detected eliminate them by means of threaded joints retorque.

Change failed hoses and high pressure hoses.

6.4.1.7 Operation 6. Check of the condition of the wires in the engine compartment

Review the condition of the wiring, wire bundles in the engine compartment and the

condition of visible parts for abrasion, melt or damage of outer insulation.

Should the above faults be discovered, proceed as follows:

- restore the damaged areas using insulation tape;

- eliminate the cause that has lead to insulation damage;

6.4.1.8 Operation 7. Inspect/clean the engine water radiator

Check cleanness of hood mask and water radiator core. In case they are clogged

clean them with soft brush and blow with compressed air. Direct an air flow in direction

shown with arrow from top downward.

In case of severe water radiator clogging rinse it with hot water under pressure not

more than 0.2 MPa and blow it off with compressed air or clean the radiatore core with a

help of washing device. radiator cores must be cleaned both from the hood mask side and

from the engine fan side.

ALKALINE SOLUTIONS AND CORROSIVE DETERGENT COMPOSITION MUST

NOT BE USED!

Loading...

Loading...