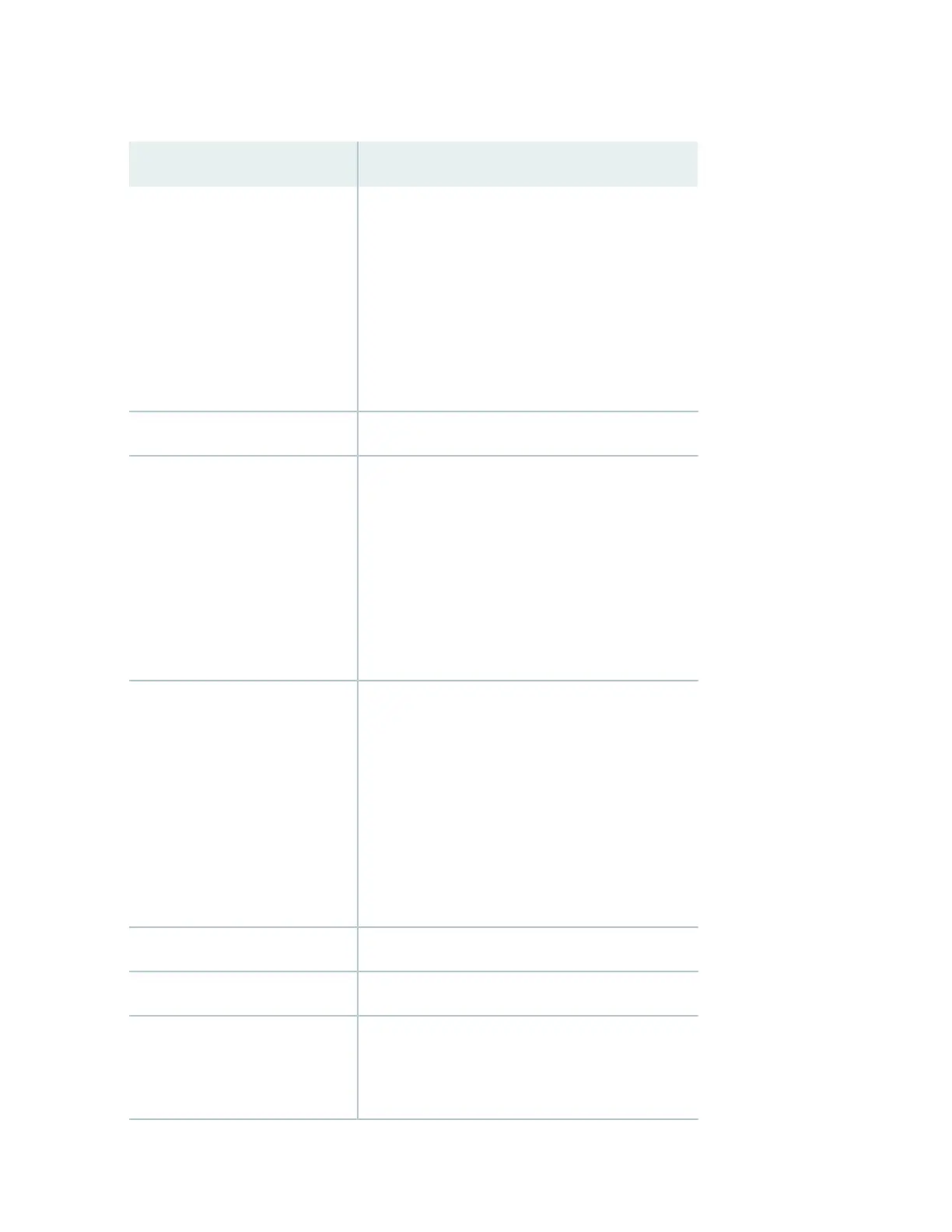

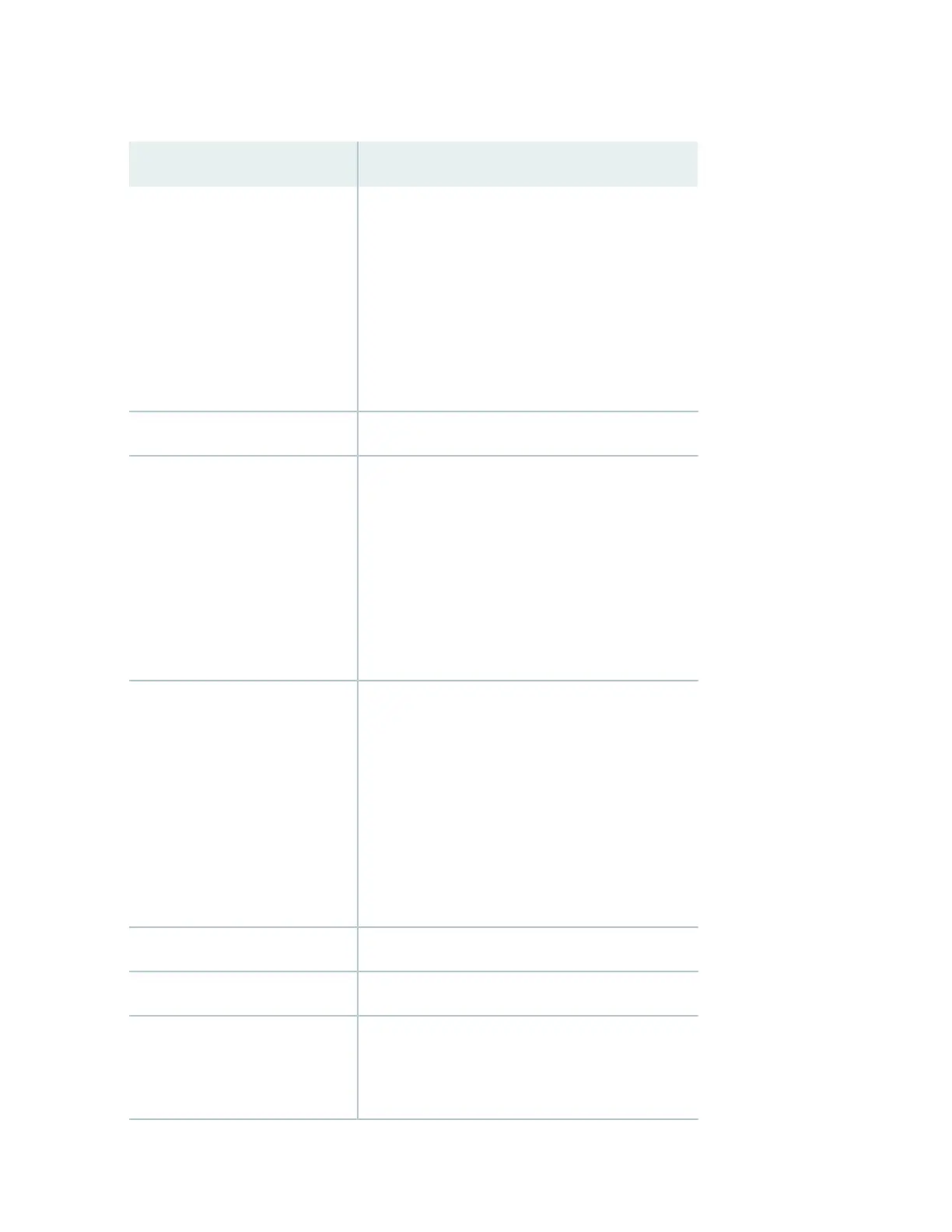

Table 98: Tools and Parts Required for Component Replacement (continued)

Tool or PartComponents

Phillips (+) screwdrivers, numbers 1 and 2

7/16-in. (11 mm) hexagonal-head external drive socket

wrench, or nut driver, with a torque range between

23 lb-in. (2.6 Nm) and 25 lb-in. (2.8 Nm) tightening

torque to attach the ground wire.

1/4-in. slotted screwdriver and 5/32-in. (4-mm) Allen

wrench to attach input terminal wires of the AC power

cord.

AC power cord

Phillips (+) screwdrivers, numbers 1 and 2Craft interface

Phillips (+) screwdrivers, numbers 1 and 2

7/16-in. (11-mm) hexagonal-head external drive socket

wrench, or nut driver, with a torque range between

23 lb-in. (2.6-Nm) and 25 lb-in. (2.8-Nm) tightening

torque to attach the ground wire.

1/4-in. slotted screwdriver and 5/32-in. (4-mm) Allen

wrench to attach input terminal wires of the AC power

cord.

DC power distribution module

7/16-in. (11 mm) nut driver or socket wrench

CAUTION: You must use an appropriate

torque-controlled tool to tighten the nuts. Apply

excessive torque damages the terminal studs and the

PDM. The absolute maximum that may be applied to

this nut is between 23 lb-in. (2.6 Nm) and 25 lb-in.

(2.8 Nm).

NOTE: This does not apply to the DC PDM (240 V

China).

DC power supply cable

Phillips (+) screwdrivers, numbers 1 and 2Fan trays (upper and lower

Phillips (+) screwdrivers, numbers 1 and 2Air baffle

Phillips (+) screwdrivers, numbers 1 and 2

Blank panels (if component is not reinstalled)

Electrostatic bag or antistatic mat

MPC

356

Loading...

Loading...