Maintenance 6-3

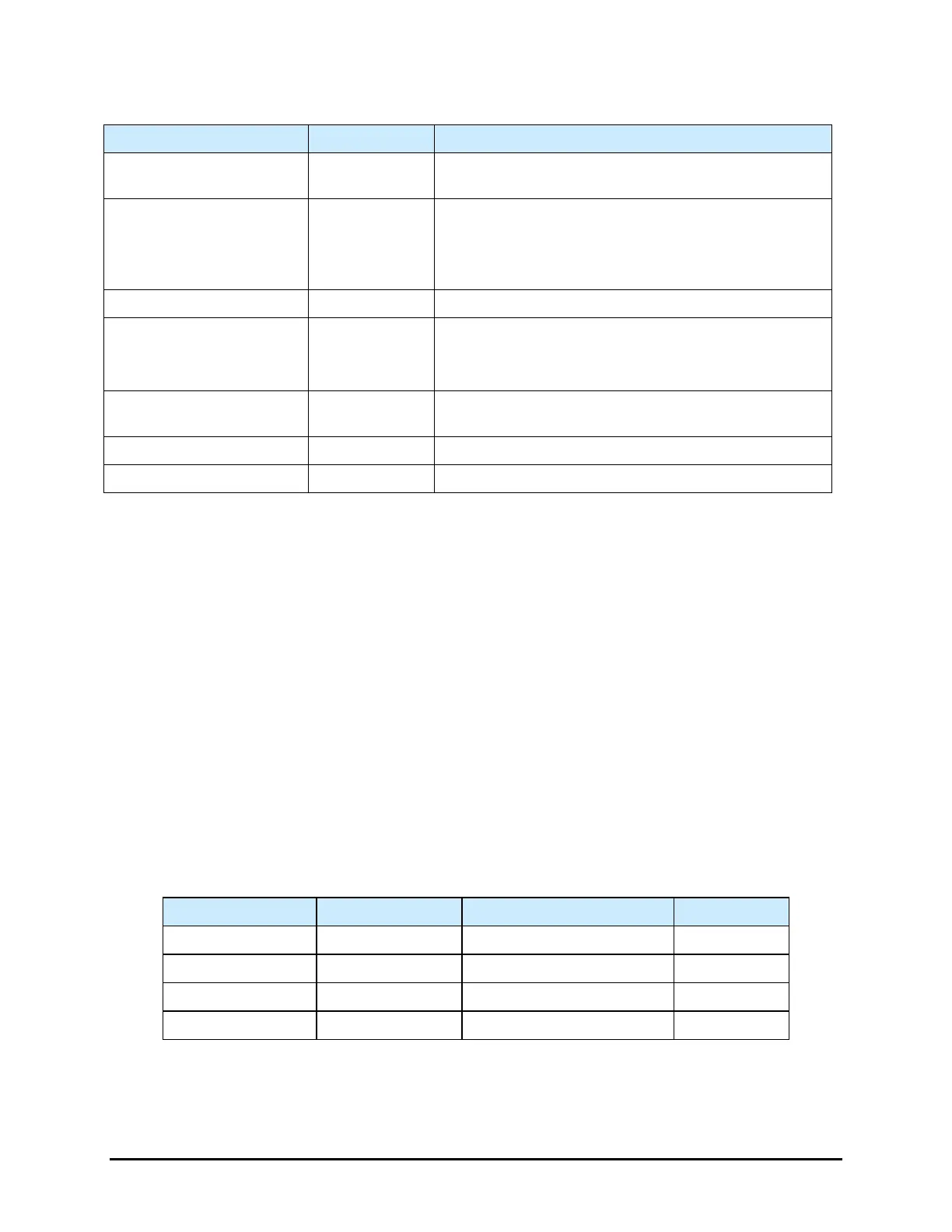

Table 6-1 Routine Maintenance Procedures (Continued)

Task Frequency* Instructions

Lubricate XY Axes Linear

Guides

Every 3 months See 6.10.2 Lubricating the Linear Guides.

Clean Encoder Strips and

Read Heads

Every 3 months

Using lint-free cotton pads or swabs wetted with

alcohol, wipe the full length of the encoder strips and

inspect for damage. Similarly, clean the read heads to

remove dirt, dust, or foreign material.

Reset Laptop Battery Every 6 months See 6.8 Computer Battery Reset.

Lubricate the Cables and

Linear Guides

Every 6 months

Every 3 months

for 24/7 use

See 6.10 Lubricating the Cables and Linear Guides.

Tension Mechanical Drive

Cables

Every 6-12

months

See 6.11 Tensioning the Cables.

Tension Conveyor Belts As Needed See 6.13 Tensioning the Conveyor Belts.

Replace Conveyor Belts As Needed See 8.10 Replacing the Conveyor Belts.

* Frequency is based on average use. High use 24/7 customers may need to perform maintenance procedures more frequently.

6.5 Replacing Consumables

Consumables are items that are discarded and replaced on a regular basis. The following items are

common consumables and should be replaced at the intervals recommended in Table 6-1.

Tools and Materials Needed

• Replacement Purge Boot (See Table 6-2)

• Replacement 1 oz. (29 ml) Plastic Cups (P/N 58-0030)

• Personal Protective Equipment (as required)

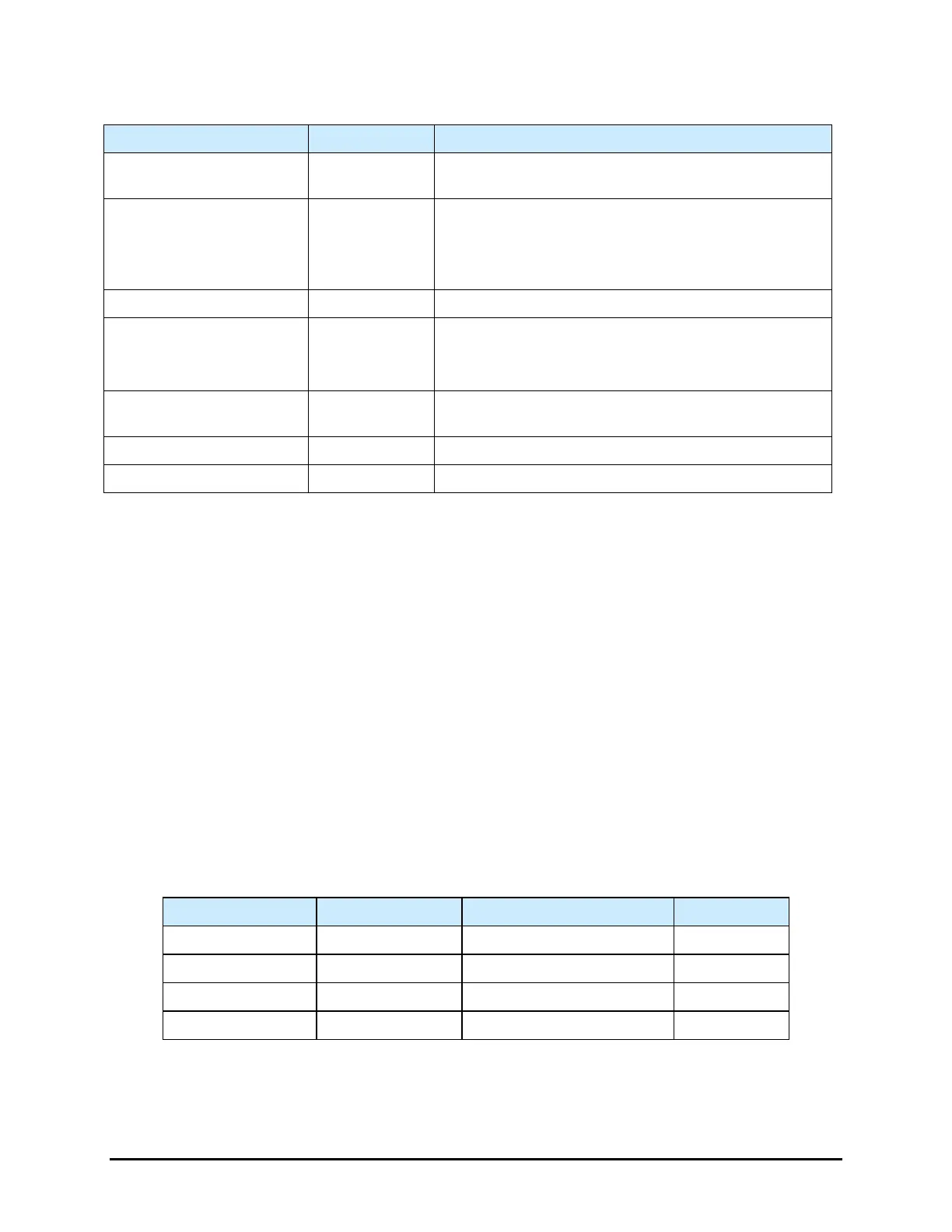

Table 6-2 Purge Boot Colors, Sizes, and Compatible Needles

Purge Boot Color Inside Diameter Compatible Needle Gages Part Number

Orange 0.5 mm (0.020-in.) 26, 27, 30, 32 01-0019-00

Pink 0.8 mm (0.031-in.) 22, 23, 24, 25 01-0021-00

Green 1.1 mm (0.045-in.) 19, 20, 21 01-0018-00

Olive* 3.0 mm (0.120-in.) 14, 15, 16, 18 01-0022-00

*Recommended size for nozzles on DJ-2000 and DJ-9000 Series Dispensing Valves.

Loading...

Loading...