1-4 Introduction

1.9 S2-900 Series Features

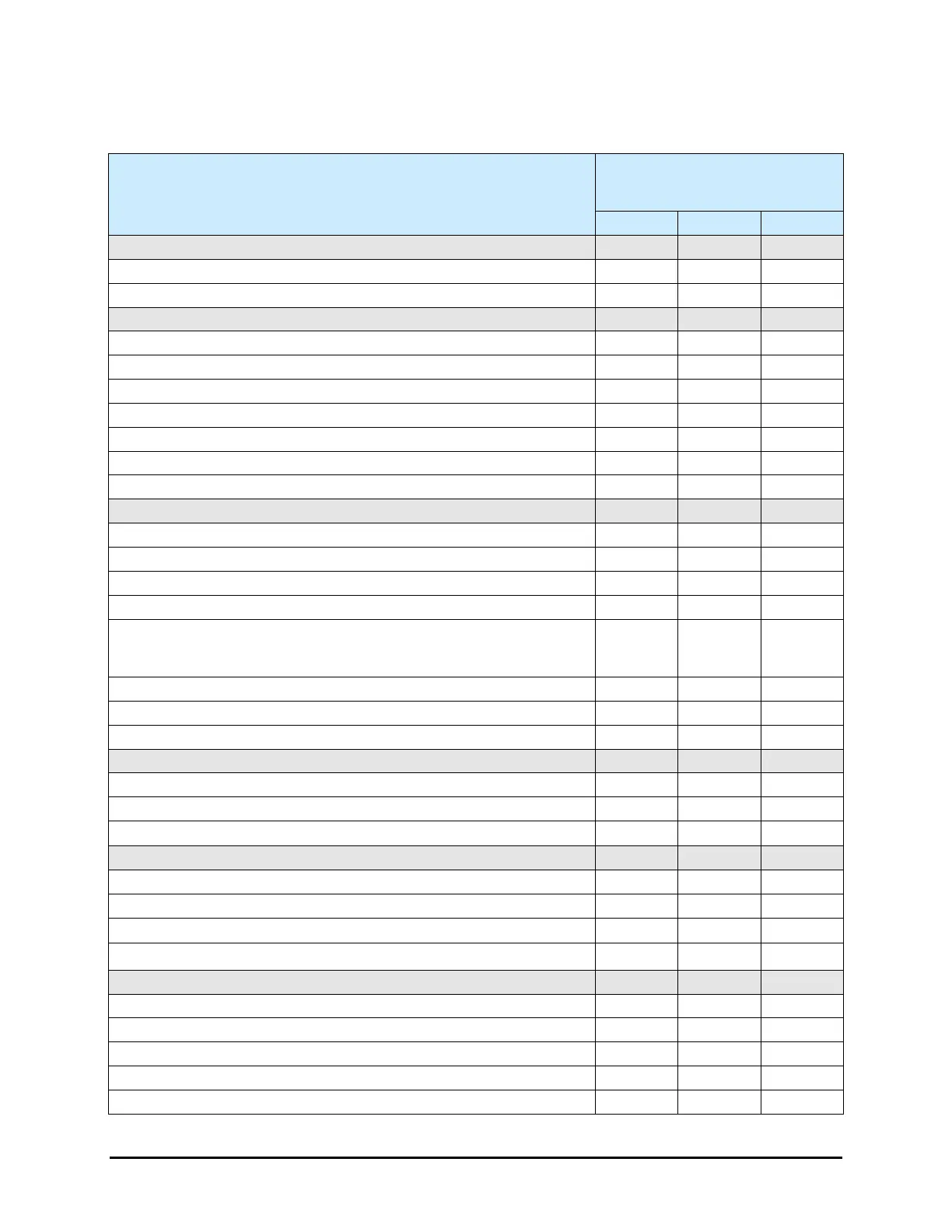

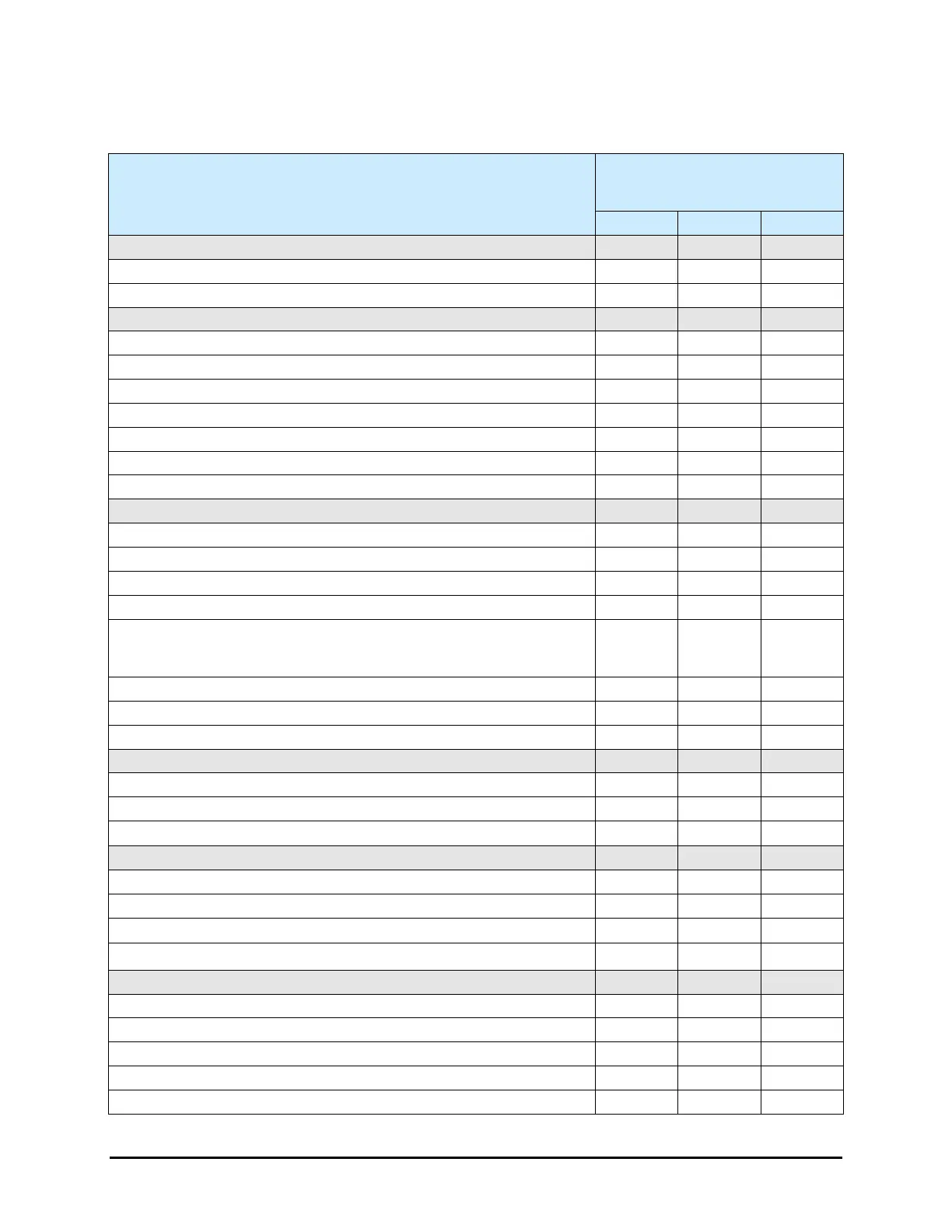

Table 1-2 Standard/Optional Features

System Features

= Standard

= Option

NA = Not Available

Computer and Software

Laptop with Windows Operating System

Fluidmove

6.X or later

Standalone / In-Line Conveyor

Stations per lane: 1 (2 or 3 stations are options)

Rail Clamps

NA NA

Lift Table

Multimove Conveyor Capability

Conveyor Belts (6-mm flat belt, 4-mm flat belt, 3-mm O-ring)

Dispense Tip Position and Maintenance

Service Station: Dispense Tile, Tactile Z Sensor, Vacuum Purge Station

Integrated Weight Scale for closed-loop process controls

Mass Flow Calibration (MFC) for needle dispensing

Calibrated Process Jetting (CPJ) for jet dispensing

Laser Height Sensor

High-accuracy: 200µm diameter circle (small dot)

Highest accuracy: 700 x 200µm oval

Laser Height Sensor for Transparent, Reflective Surfaces

Tactile Height Sensor

Programmable Tilt and Rotate

ESR

IntelliJet

NA

Jet Valves (DispenseJet, NexJet)

DV-Series Valves (See 1.10.7 Dispensing Valves)

Heater Options and Control

Needle Heater

Substrate Heating: contact or impingement

Controlled Process Heat (CpH™)

Process Development Hot Plate (requires large lift table)

Vision: Auto Pattern Recognition/Digital Camera

Monocle™ Vision Package with 5-axis On/Off axis lighting

Part Illumination: Red/Blue/Green

Low-Angle Off-Axis Red Light

™

Loading...

Loading...