Introduction 1-3

1.7 S2-900 Series Overview

With its flexible, scalable configuration, the S2-900 Series features technologically advanced software

and hardware control and can be customized to your needs. All S2-900 models have the same base

structure which simplifies operator training, maintenance, and spares when customers own different

models.

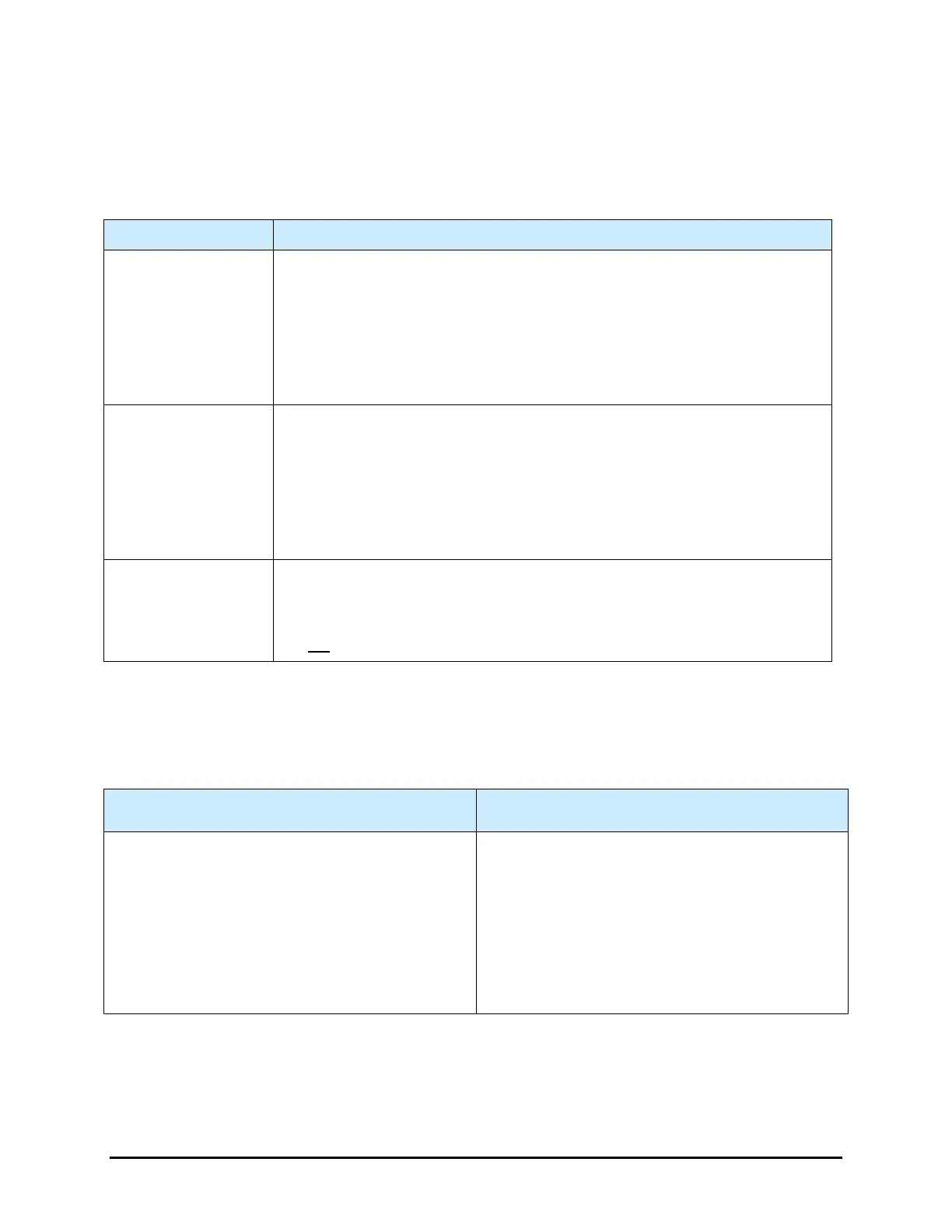

Model Number Overview

S2-900

(single / dual lane)

The S2-900 base model, is fully configurable for your target application. Pre-

and post-queue stations can be added for higher throughput or as buffer

stations. Substrate heating and lift tables can be added as an option. Systems

come standard with a single-lane conveyor or can be upgraded for dual-lane

operation. The S2-900 is pre-configured to allow for operation of the IntelliJet

®

Jetting System with a simple piezo driver kit upgrade option. Additional options

can be added to enhance throughput and process control, such as Mass Flow

Calibration (includes scale) and Programmable Fluid and Valve Pressure.

S2-900P

(single / dual lane)

The Spectrum II Premier, S2-900P, is a premium, pre-configured dispensing

platform. The S2-900P comes standard with the IntelliJet

®

Jetting System,

substrate heating, mass flow calibration scale, programmable fluid and valve

pressure regulators, Fids-on-the-Fly™, and the Monocle™ Vision Package.

The system can be configured with 1, 2, or 3 heat stations depending on

application requirements. Dual-lane operation is an additional option to expand

substrate heating to up to 6 stations. Additional options can be added that

enhance throughput and process control.

S2-9XXC

(cleanroom system)

The S2-9XXC models are equipped with a stainless steel enclosure, and the

high-flex electrical cables are enclosed in a cleanroom-certified jacket to

reduce particle generation and outgassing. An ULPA filter provides a

downward particle-free air column within the dispense area. S2-9XXC systems

are not compatible with the IntelliJet

®

Jetting System.

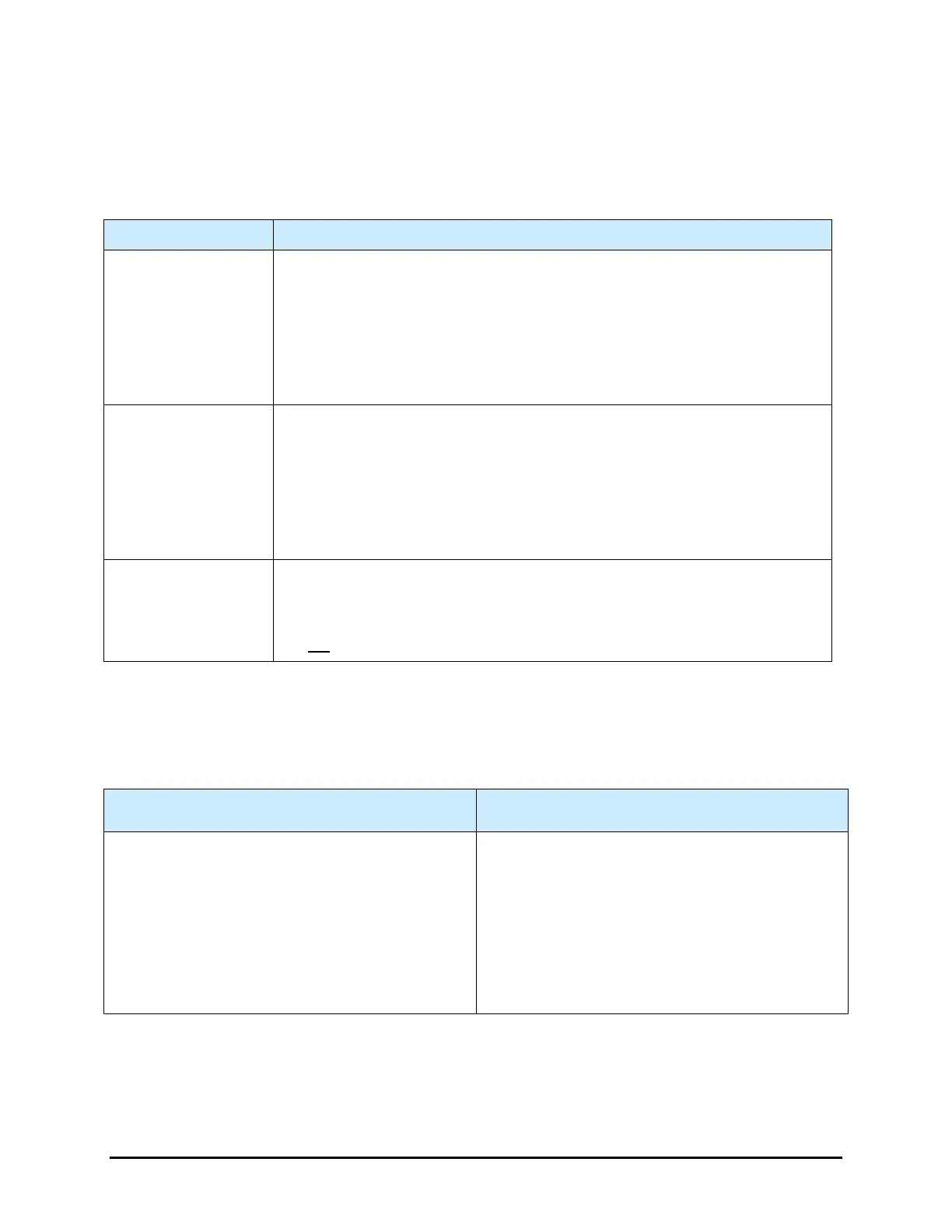

1.8 Supported Applications

Contact Nordson ASYMTEK for applications not listed.

Table 1-1 Recommended Applications

S2-900

S2-900P

• 2

nd

Level Underfill

• Encapsulation

– Silicone

– Epoxy

• Corner/Edge Bond

• Precise Coating

• Emerging PCBA

• Solder Paste Sealing Lines

• Emerging ASPA

– 3D IC

– Chip on Wafer

– Chip on Strip

• Emerging EMA

– Camera Modules

• Life Science

• Precision Volume Dispensing

Loading...

Loading...