Introduction 1-19

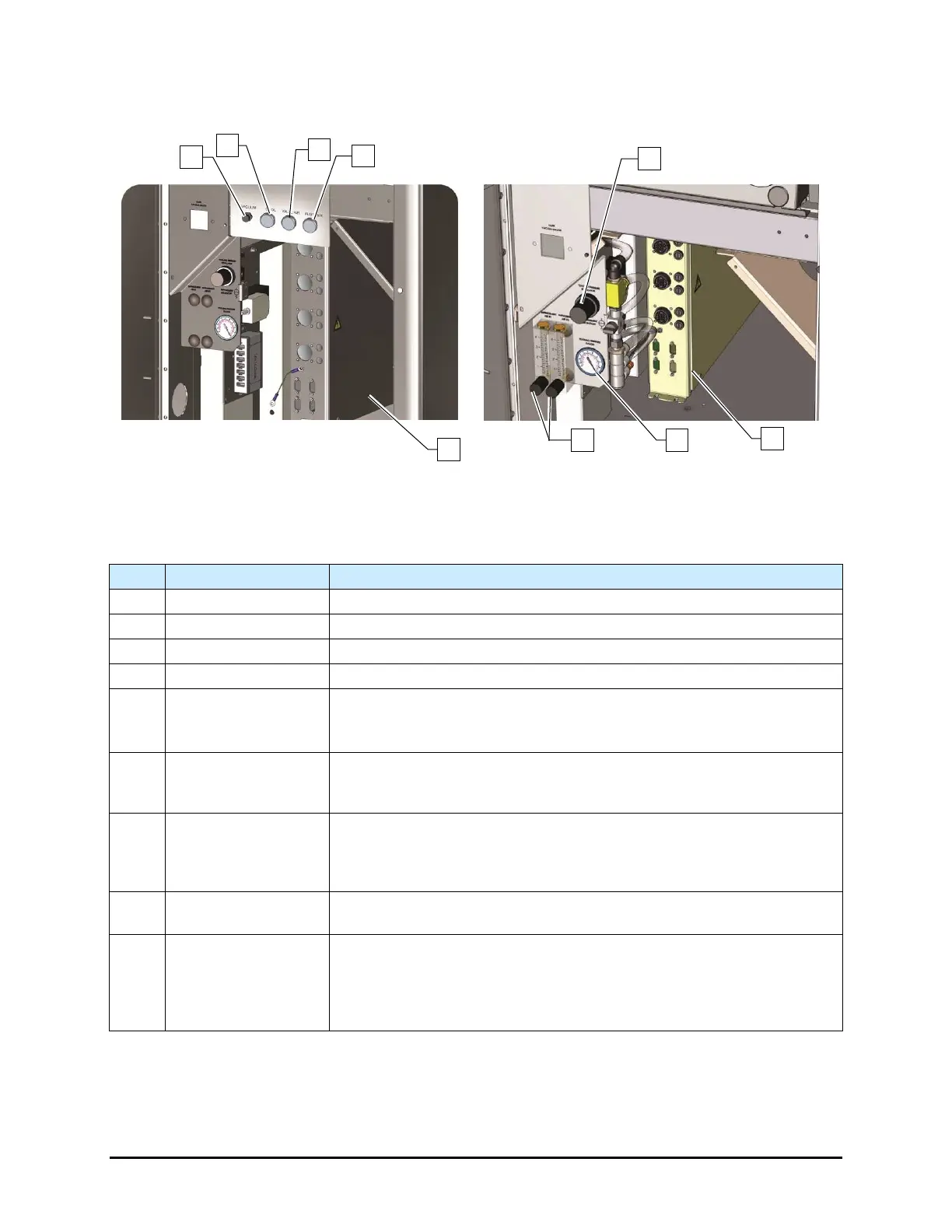

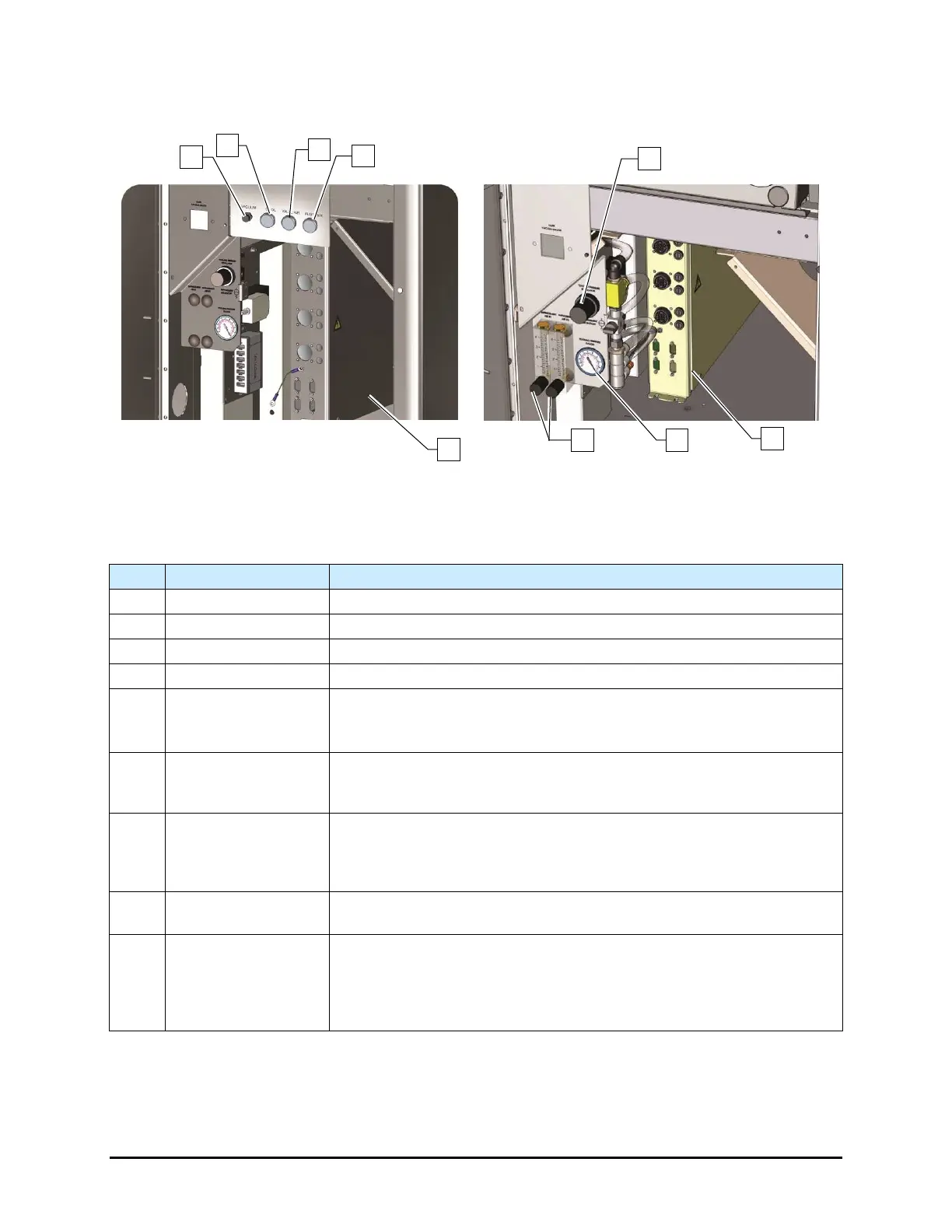

1.11.6 Front Cabinet

NOTE The S2-900P Series features programmable fluid and valve pressure. Air pressure is set

through the Fluidmove software. This feature is an option on the S2-900 Series Systems.

Controls the air pressure supplied to the vacuum air.

2 Cooling Air Regulator Controls the air pressure supplied to the cooling air.

Controls the air pressure supplied to the valve air.

Controls the air pressure supplied to the fluid air.

5

Conveyor Controller

Module (systems

without heat)

Controls all conveyor functions (motors, sensors, pneumatics, etc.). If

your system is equipped with dual conveyors, two Conveyor Controller

Modules are required.

6

Tooling Pressure

Regulator

Controls the air pressure supplied to the stop pins and lift tables. The

regulator receives air from the main air regulator located on the back of

the dispensing system.

7

Conveyor/Heater

Module (systems with

heat)

Controls all conveyor functions (motors, sensors, pneumatics, etc.). It

receives power from the Power Manager and supplies AC power to the

substrate heaters in the dispensing area. If your system is equipped with

dual conveyors, two Conveyor/Heater Modules are required.

8

Tooling Pressure

Gauge

Displays the air pressure supplied to the stop pins and lift tables.

9

Impingement

Flowmeters*

(S2-900P)

Not on S2-9XXC

Controls the airflow through the impingement heaters in the dispensing

chamber. A manual shut-off valve controls the air going to the

flowmeters. Note: Depending on system configuration, a dispensing

system may have up to six (6) flowmeters (pre-dispense, dispense, and

post-dispense for Conveyor 1 and Conveyor 2).

Figure 1-7 Front Cabinet

*Impingement flowmeters are standard on the S2-900P. The flowmeters may be optionally replaced by

Controlled Process Heat (CpH) software. See 5.15 Controlled Process Heat.

Loading...

Loading...