Maintenance 6-23

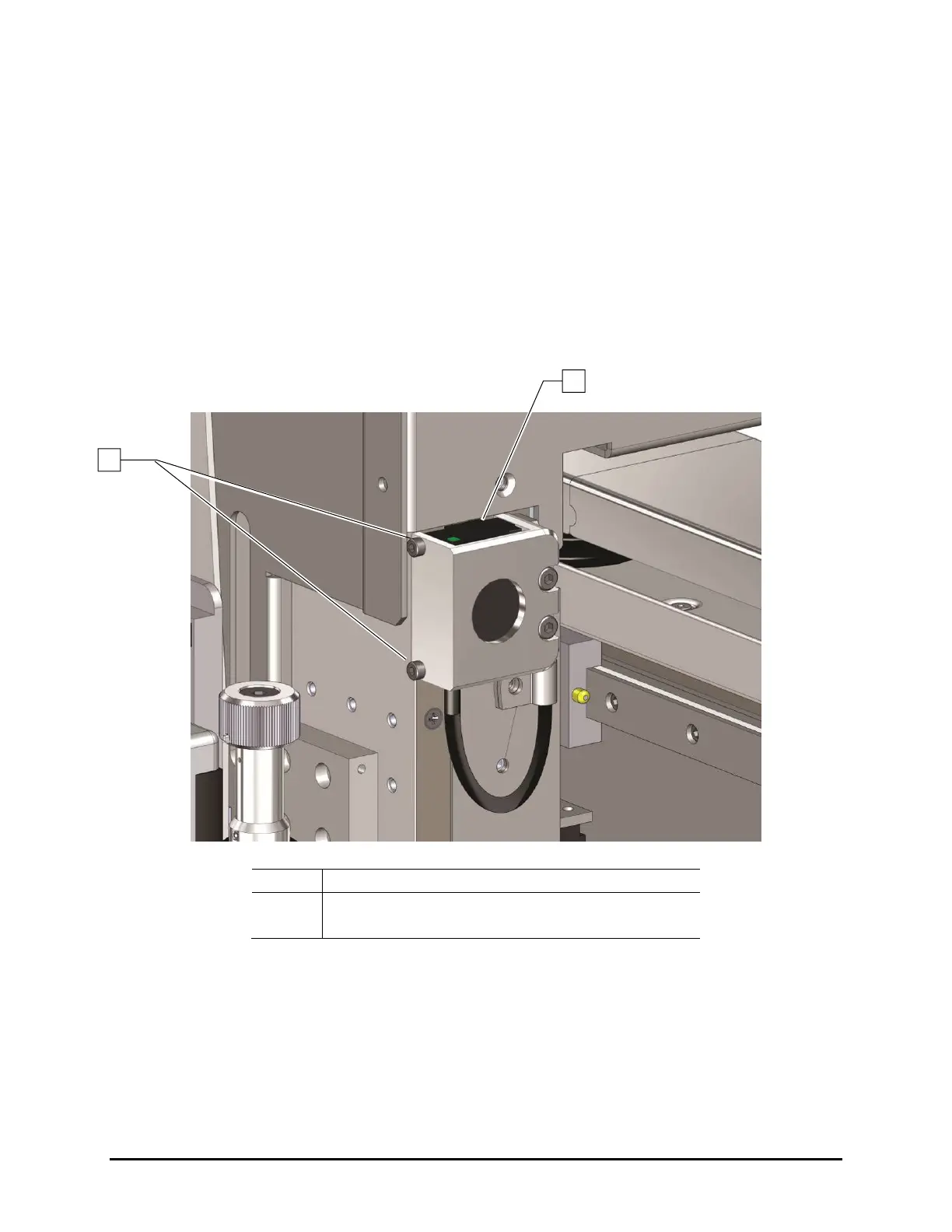

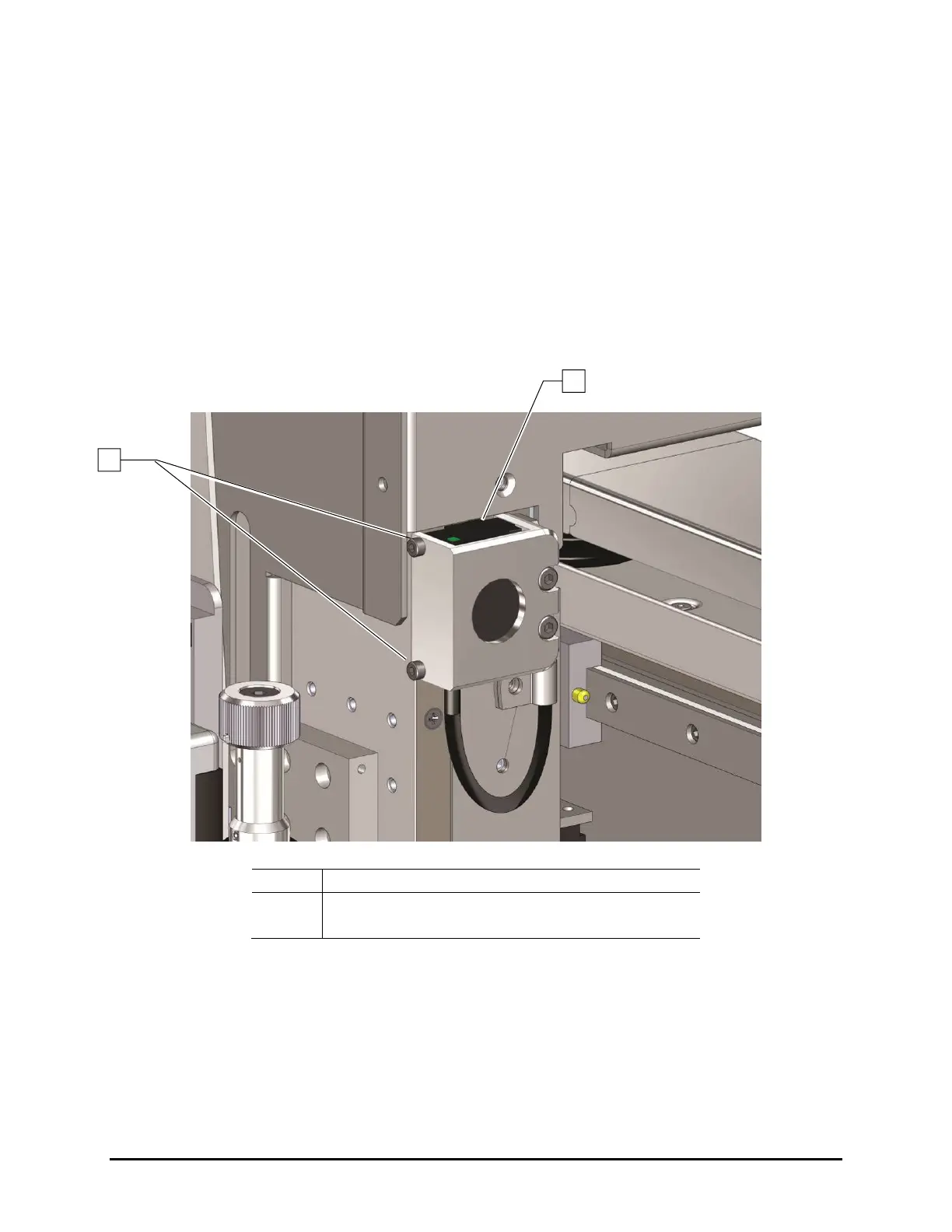

6.12.3 Adjusting the Z-Axis Linear Encoder Gap

To adjust the Z-Axis Linear Encoder gap:

1. If necessary, power ON the dispensing system.

2. Exit Fluidmove.

3. Open the dispensing system hatch.

4. Verify that the light beacon is yellow and that all axes move freely by hand.

5. Place the 0.8 mm gauge in the space between the linear encoder head and the linear encoder

strip.

6. To adjust the Z-axis linear encoder gap, use the 3 mm hex key to loosen the two mounting

screws on the encoder bracket.

Item Description

1 Linear Encoder

2 Encoder Mounting Screws (2)

Figure 6-17 Adjusting the Linear Encoder Height

7. Apply Loctite thread locker to the hex bolt threads.

8. Press the encoder against the gauge. Make sure that the encoder is level and not pinching

the gauge.

You should be able to slide the gauge up and down beneath the encoder. If the gauge

slides too easily, the gap may be too wide.

1

2

Loading...

Loading...