Section 22: HEATING AND AIR CONDITIONING

PA1553

25

Replace the brushes if less than ¾ inch (19

mm). New brush length is 1-¼ inch.

To replace brushes, proceed as follows:

1. Set ignition key switch to the “OFF” position.

2. Remove the protective screen band from the

motor housing by pulling down the spring

loaded fastener.

3. Lift the spring, remove and replace brushes

as per the following procedure: “SEATING

BRUSHES”.

4. Reverse installation procedure.

9.3.5 Seating Brushes

Grinding consists in giving to the seating face of

a new brush the exact same curvature of the

commutator so that good mechanical and

electric contact of the brush is made.

For best results, remove oil and grease from

commutator before applying brush seater.

NOTE

The new motor brushes are provided with a

preformed seating face which is approximately

the same curvature as the commutator.

Grinding/honing will give an exact match in

curvature. The advantage of preforming is to

appreciably shorten the time required for

grinding.

Grinding is generally done on the machine itself,

in accordance with various processes' and

conformably to the importance and the type of

machines:

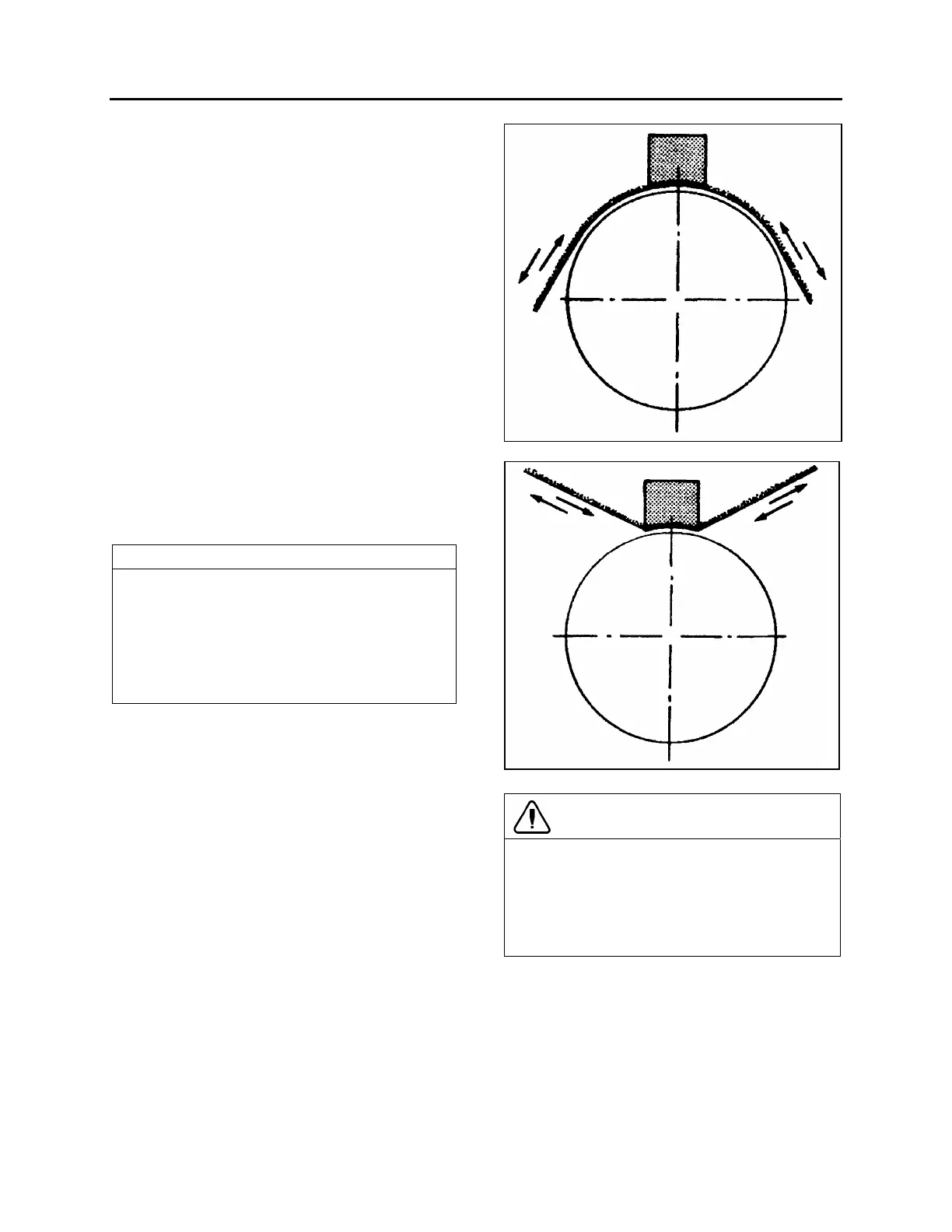

a) Grinding with abrasive cloth (60 grit

sandpaper) applied to the commutator must

be done by hand. With the new brushes

installed in brush holders and pressing

against the abrasive cloth, rotate the

armature (by hand) until satisfactory seating

of each brush is achieved (Refer to figure

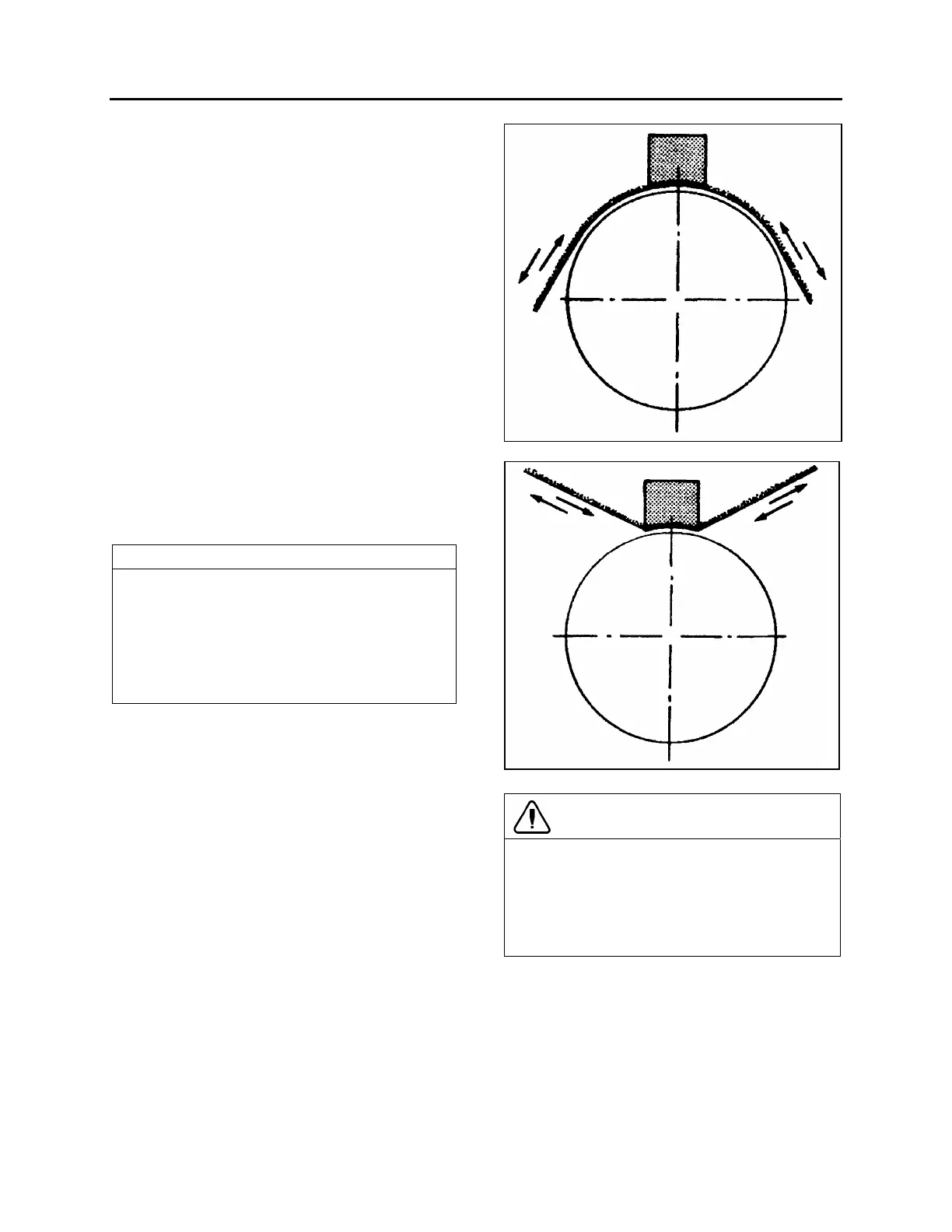

25). It is necessary to avoid raising the cloth

under the brushes otherwise it would result,

after grinding, to reduce and badly definite

surfaces (Refer to figure 26).

FIGURE 25: PROPER GRINDING TECHNIQUE 22317

FIGURE 26: IMPROPER GRINDING TECHNIQUE 22318

CAUTION

If grinding with a honing stone, you must

disconnect the time delay in order to keep the

motor in 1

st

speed. If you prefer, you may also

install a jumper on the evaporator motor

between terminal E2 and A1 to bypass relay

R60 and keep the motor in 1

st

speed as well.

b) Grinding with the honing stone is always

done under reduced voltage. Dust particles

act like abrasive and wear down the brushes

exactly with the profile of the commutator.

Caution is advised here as prolonged

honing could wear the brushes and

commutator prematurely.

Loading...

Loading...