Section 26: XLII SLIDE-OUT

PA1553

5

1 SLIDE-OUT

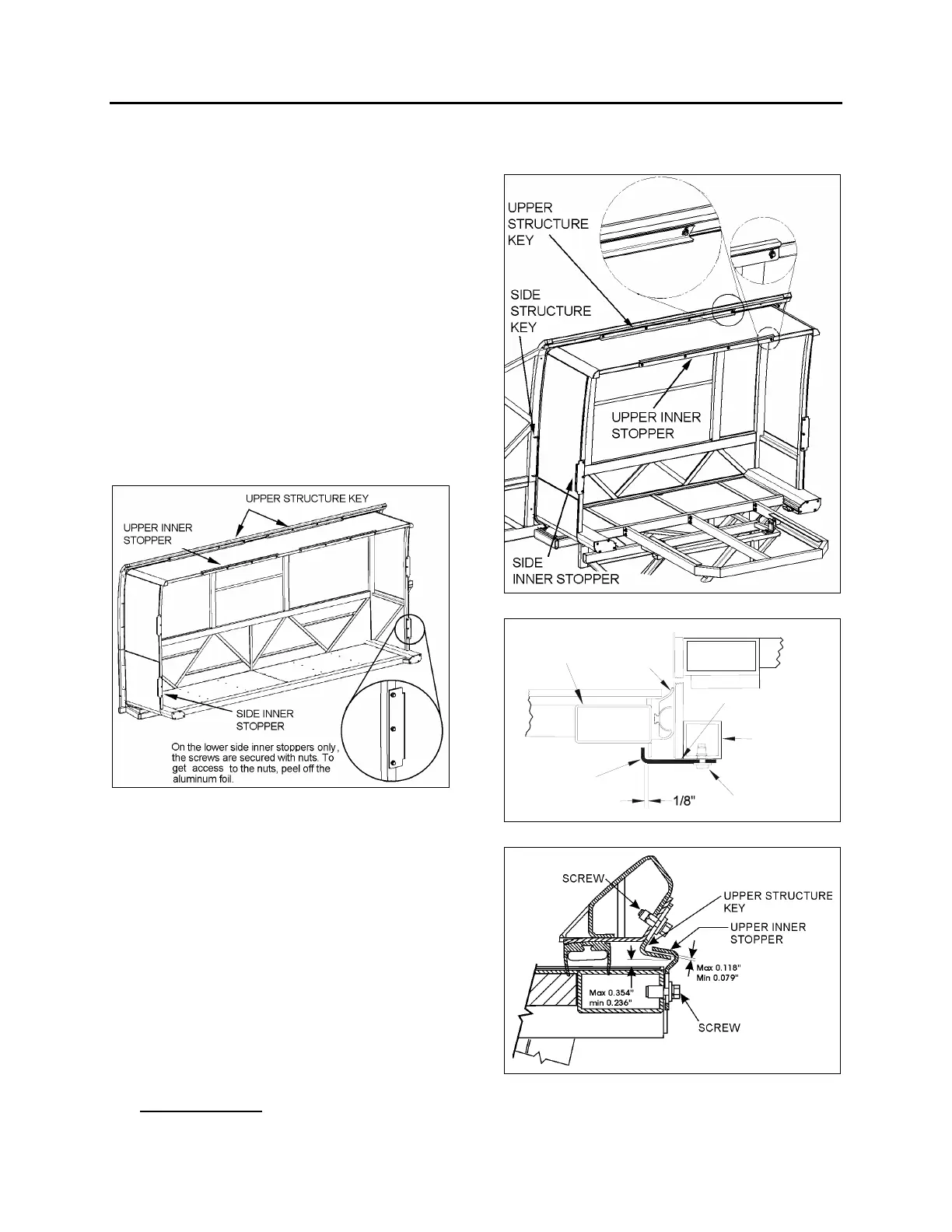

1.1 INNER STOPPER

The front slide-out is equipped with six inner

stoppers laid out in the following way: two

stoppers on the top horizontal member of the

slide-out, and two stoppers on each vertical

upright, while the rear slide-out is equipped with

only three stoppers (figure 1 and figure 2). The

upper inner stoppers are used to provide a

support to position perpendicularly the slide-out

with the vehicle structure.

The side inner stoppers are used to block the

extension of the slide-out. They act as ultimate

physical limits but take note that when the “out

limit” sensors are properly adjusted, the slide-out

extension stops before the side inner stoppers

reach the side structure keys (figure 1 & 2).

FIGURE 1 : FRONT SLIDE-OUT

1.1.1 Maintenance

Check that the inner stopper screws are tight

and that no damage or deformation has taken

place for both the side and the upper stoppers.

1.1.2 Adjustment

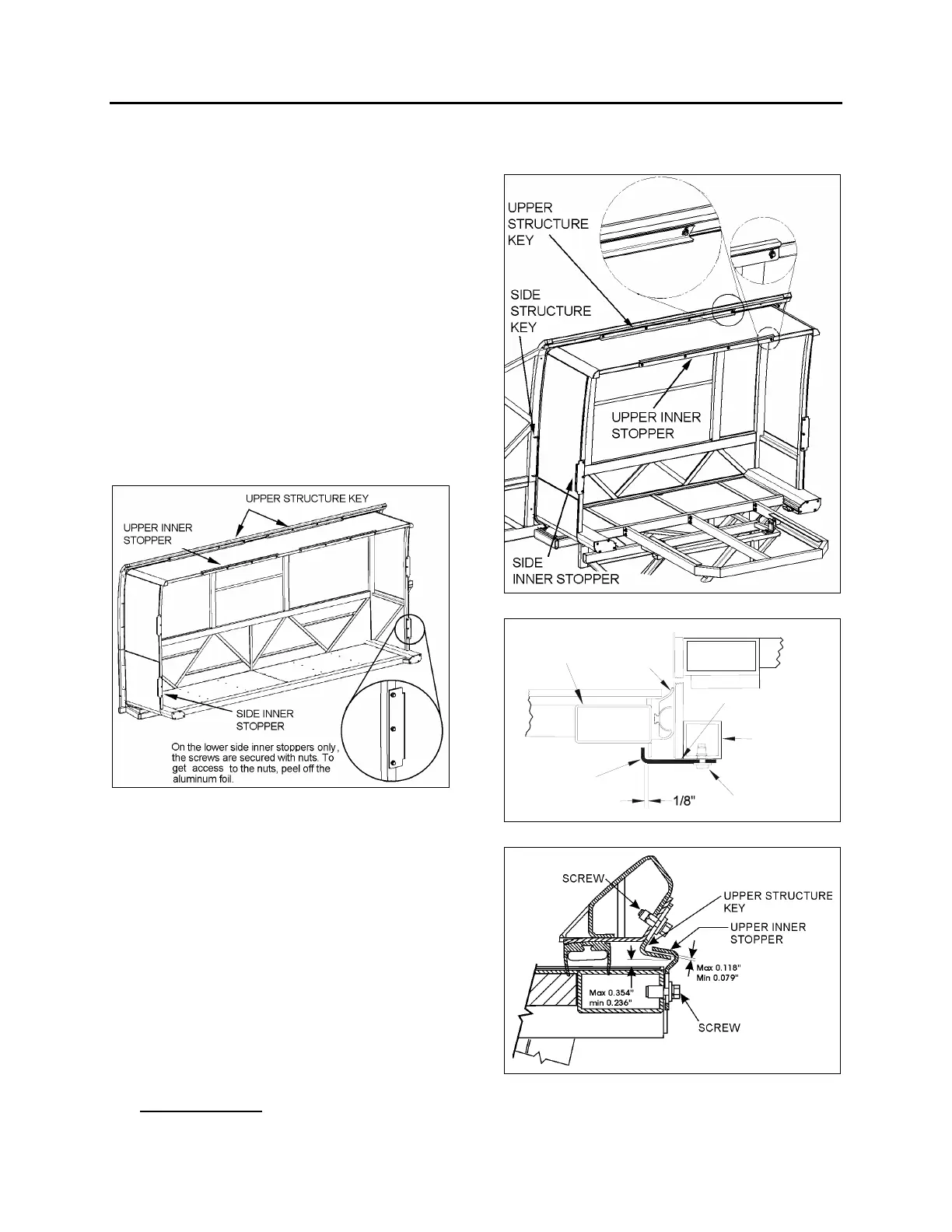

1. Adjust the side inner stoppers at 1/8" from

the vehicle side structure keys, and tighten

the screws. Make sure there is a minimum

gap of 2mm (0.079”) between the side inner

stopper and the side window pane (figure 3).

Use shim as required.

2. Adjust the upper structure key and the upper

inner stoppers according to FIGURE 4 with

the seal deflated

. When inflating, the seal

presses the roof structure upward and at

that moment, the upper inner stopper comes

into contact with the upper structure key

FIGURE 2 : REAR SLIDE-OUT

SCREW

SLIDE-OUT

STRUCTURE

SEAL

VEHICLE

STRUCTURE

SIDE INNER

STOPPER

2mm (0.079in)

MINIMUM GAP

FIGURE 3 : SIDE INNER STOPPER ADJUSTMENT

FIGURE 4: UPPER INNER STOPPERS ADJUSTMENT

Loading...

Loading...