Section 26: XLII SLIDE-OUT

PA1553

6

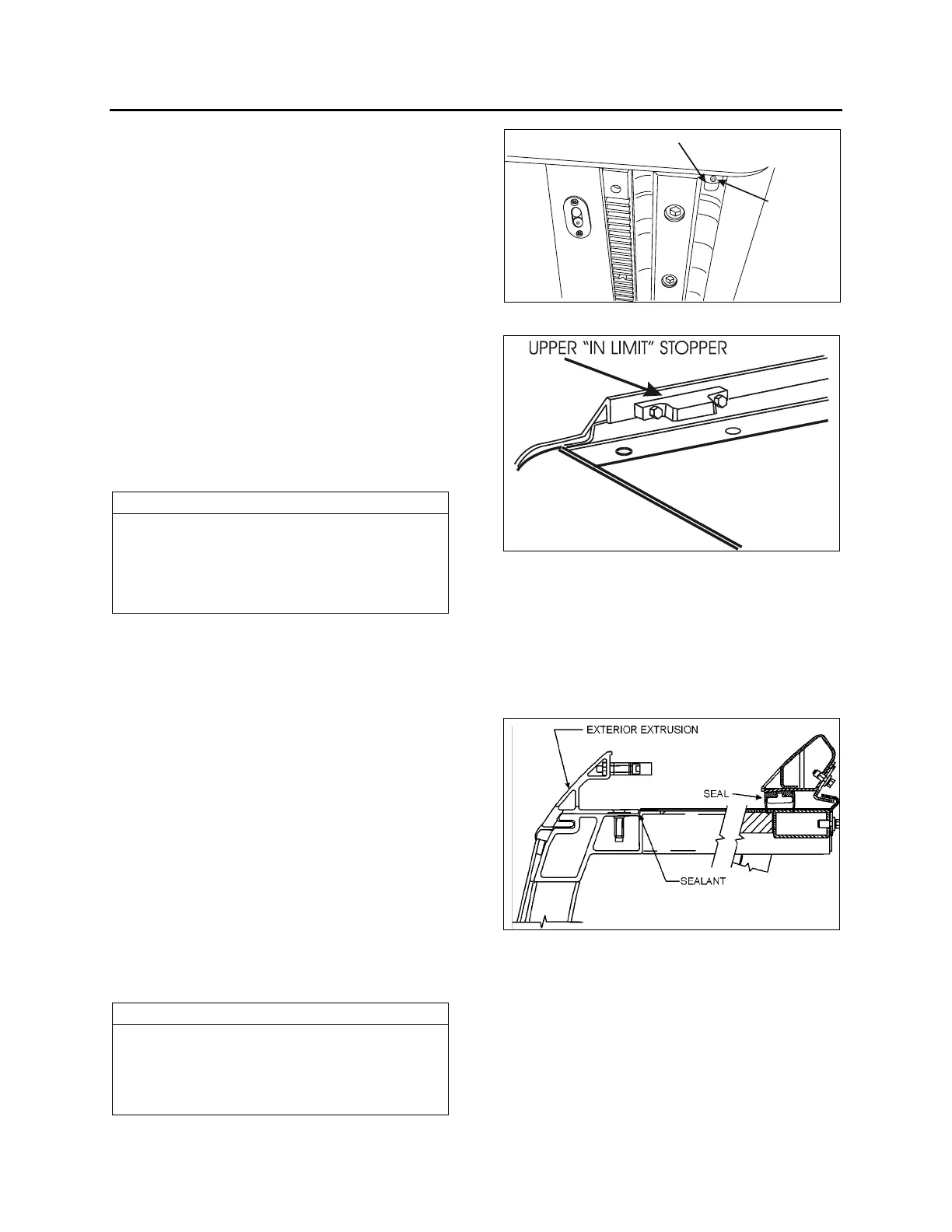

1.2 "IN LIMIT" STOPPER

Each slide-out has four "in limit" stoppers. Two

"in limit" stoppers are mounted on the exterior

extrusion at the top of the slide-out (FIGURE 6)

and two other "in limit" stoppers are mounted

under the slide-out, next to the rail (Figure 5).

These stoppers are use to position the outer

face of the slide-out flush with the vehicle body

when retracted.

1.2.1 Maintenance

Check that the "in limit" stoppers are clean and

that there is no foreign matter accumulated

between the stopper and their bearing surface.

Check that the screws and set screws (where

applicable) locking the stoppers in proper

position are tight.

1.2.2 Adjustment

NOTE

To properly adjust the “in limit” stoppers, the

slide-out system must be turned off to prevent

the “in limit” sensors from stopping the slide-

out movement before having the “in limit”

stoppers contacting their bearing surface.

1. Extend the slide-out partially.

2. Set the ignition switch to the OFF position.

3. To adjust the lower "in limit" stoppers,

loosen the set screw and then rotate the

stopper CW or CCW to move it back or

forward depending on the required

adjustment. To adjust the upper plastic "in

limit" stoppers, add or remove shims as

required between the stopper and the

extrusion.

4. Using the manual override procedure

(section 18), move the slide-out up to its full

"in" position.

5. Using a straight edge, check if the outer face

of the slide-out is flush with the vehicle body

with the stoppers contacting their bearing

surface. Readjust the stoppers if necessary.

6. Readjust the “in limit” sensor.

NOTE

To make sure that the lower “in limit” stoppers are

contacting their bearing surface (the acetal plastic

blocks) when the slide-out is closed, put white paint

on the “in limit” stopper before and check if the

acetal plastic blocks are marked with paint.

LOWER “IN LIMIT” STOPPER

SET

SCREW

FIGURE 5: LOWER "IN LIMIT" STOPPER

FIGURE 6: UPPER "IN LIMIT" STOPPER

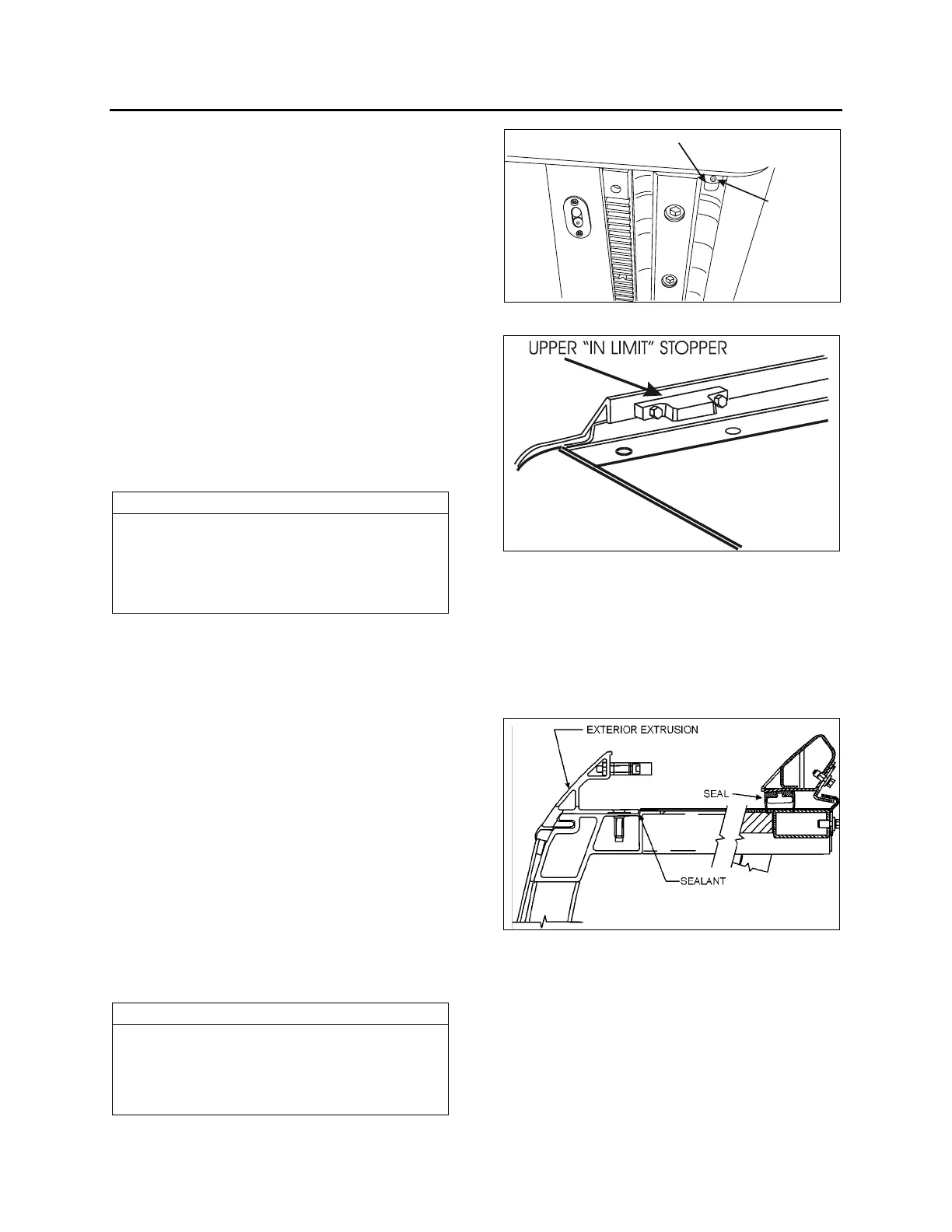

1.3 EXTERIOR EXTRUSION

The exterior extrusion function is to provide a

leaning surface for the inflatable seal. When

inflating, the seal leans against the extrusion and

presses the roof structure upward until it rests on

the inner side of the extrusion.

FIGURE 7 : EXTERIOR EXTRUSION

Maintenance

Inspect the exterior extrusion for any

deformation or deterioration. Check that the

screws are tight. Inspect the sealant condition on

screw head and between the extrusion and the

vehicle structure, and also at both ends of the

extrusion. If needed, clean old sealant and

replace with Sika 221 sealant or equivalent

product.

Loading...

Loading...