306 Rockwell Automation Publication 2198-UM002L-EN-P - October 2021

Chapter 9 Kinetix 5700 Safe Torque-off Function

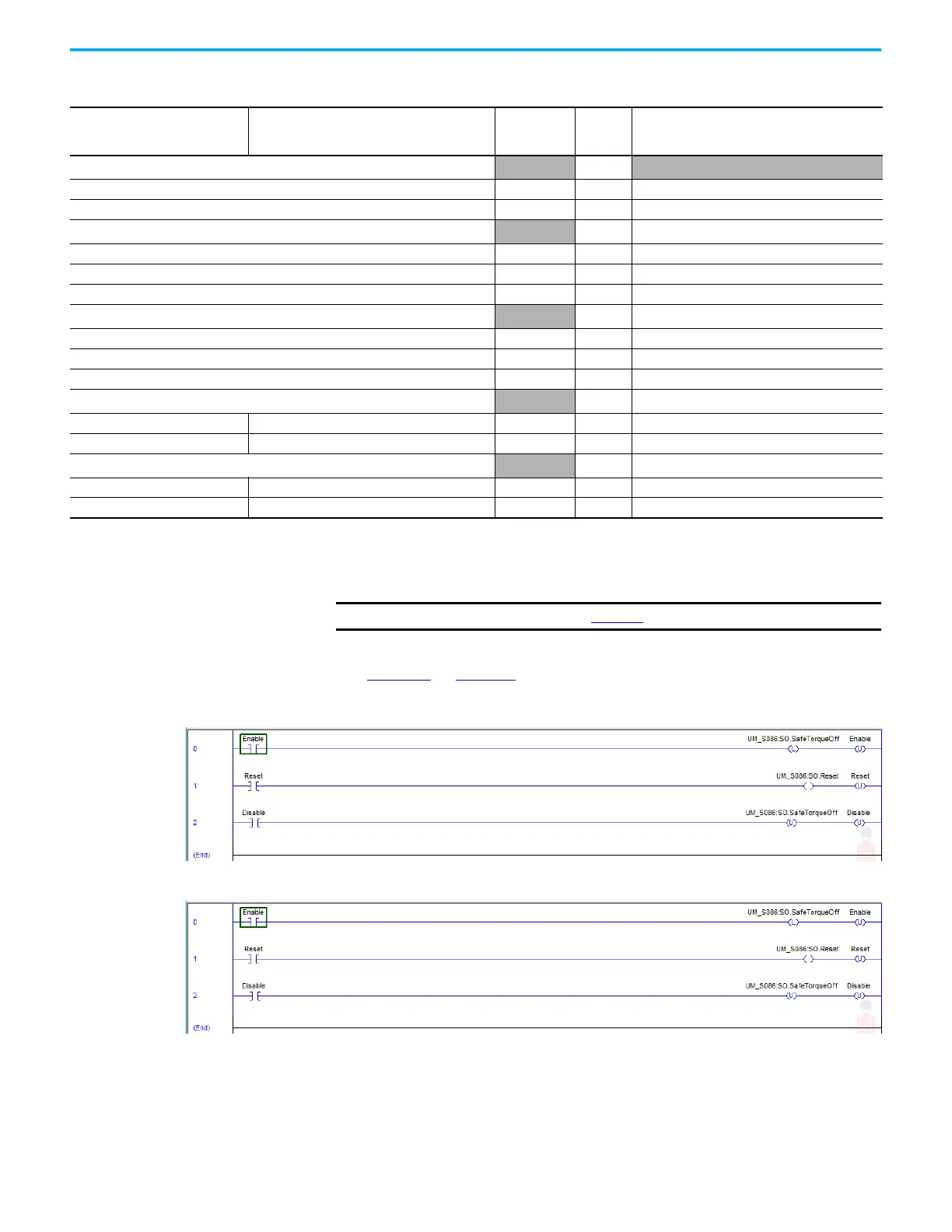

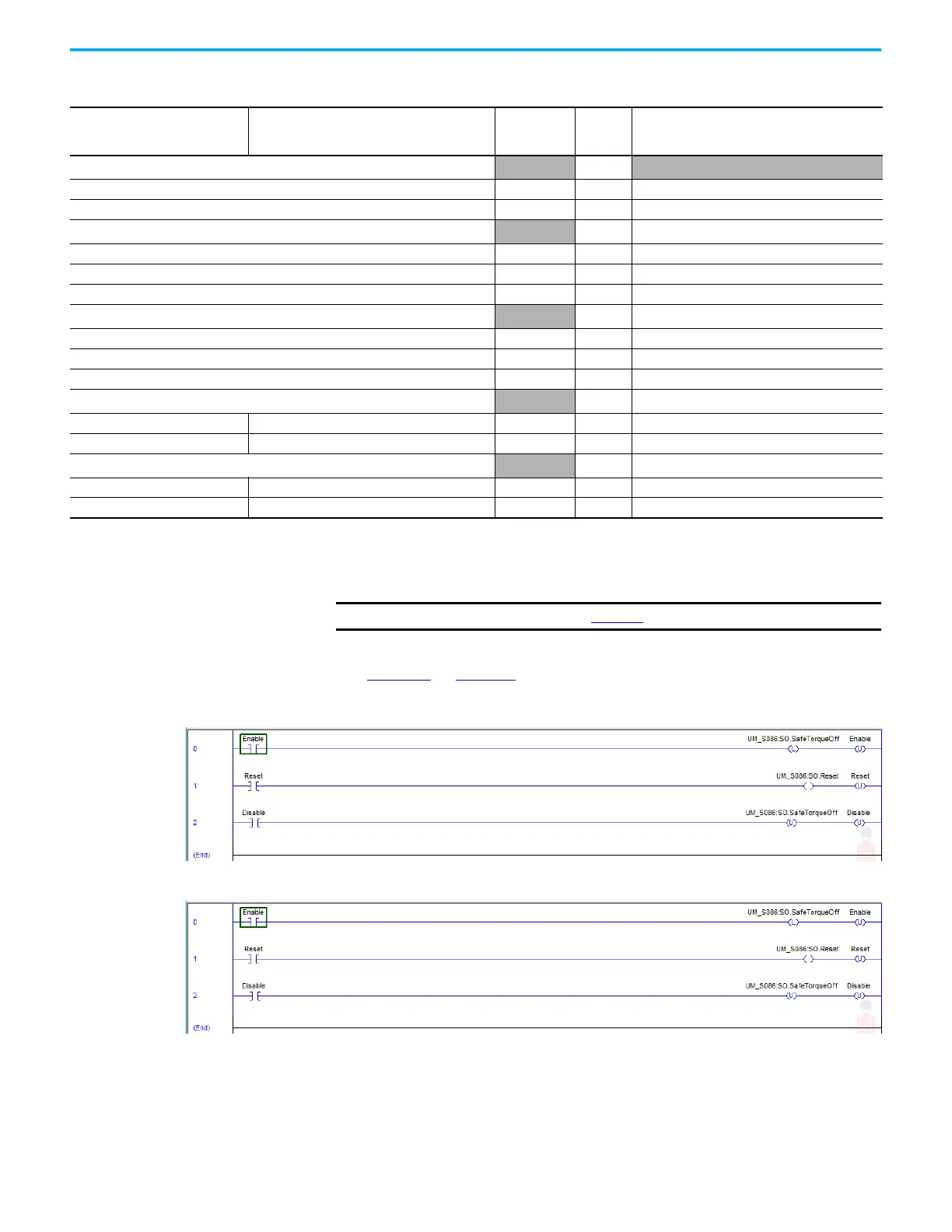

In these examples, the appropriate STO bit permits torque when the bit is high

(see Table 170

on page 304 for changes in STO tag names).

Figure 146 - STO Function (Logix Designer, version 30 or earlier)

Figure 147 - STO Function with STO Only (Logix Designer, version 31 or later)

Table 172 - Dual-axis Inverter Integrated STO Specifications

Logix Designer Tag Name

Safe Stop Only - No Feedback Tag Names

Studio 5000 Logix Designer

(version 31 and later)

Attribute

[bit]

Type Description

SI.ConnectionStatus

(1)

(2)

DINT

SI.RunMode [0] BOOL Combinations of the RunMode and

SI.ConnectionFaulted [1] BOOL ConnectionFaulted states

SI.Status1

(1)

(3)

SINT Motion Safety 1

SI.TorqueDisabled1 [0] BOOL 0 = Torque Permitted; 1 = Torque Disabled

SI.SafetyFault1 [6] BOOL 1 = STO Fault present

SI.ResetRequired1 [7] BOOL 1 = A reset is required

SI.Status2

(1)

(3)

SINT Motion Safety 2

SI.TorqueDisabled2 [0] BOOL 0 = Torque Permitted; 1 = Torque Disabled

SI.SafetyFault2 [6] BOOL 1 = STO Fault present

SI.ResetRequired2 [7] BOOL 1 = A reset is required

SO.Command1

(1)

(4)

SINT Motion Safety 1

SO.SafeTorqueOff1 SO.STOOutput1 [0] BOOL 0 = Disable Permit; 1 = Permit Torque

SO.Reset1 SO.ResetRequest1 [7] BOOL 0-->1 = Reset STO Fault

SO.Command2

(1)

(4)

SINT Motion Safety 2

SO.SafeTorqueOff2 SO.STOOutput2 [0] BOOL 0 = Disable Permit; 1 = Permit Torque

SO.Reset2 SO.ResetRequest2 [7] BOOL 0-->1 = Reset STO Fault

(1) Bits not listed are always zero.

(2) ConnectionStatus is determined by the Safety Validator in the GuardLogix controller.

(3) Status is sent from the drive to the controller using integrated safety protocol.

(4) The Command is sent from the controller to the drive using integrated safety protocol.

IMPORTANT

Only the data listed in Table 172 is communicated with SIL 3 integrity.

Loading...

Loading...